IB-19530CP

CROSS SECTION POLISHER™

The IB-19530CP features an innovatively designed, multi-purpose stage to fulfill increasingly diversified market needs and realize multi-functionality by different kinds of functional holders. The multi-purpose stage combined with specialized functional holders allows the user to perform various functions such as planar surface milling and polishing, sputter coating as well as more traditional cross-section ion milling.

Features

High throughput

The high-speed ion source and auto start function deliver milling results quickly.

Auto processing program

High-speed processing and finishing can be programmed to prepare high quality cross sections in a short period of time. Intermittent processing can also be programmed to enhance preparation of materials of low melting temperature and susceptible to ion beam irradiation.

Ease of setup

The modularized holder allows accurately milling area adjustment either inside the IB-19530CP or by utilizing an external optical microscope.

Multi-purpose stage

Additional functions including planar surface milling and ion beam sputter coating can be utilized via a variety of holders.

Long life shielding plate

The life of shielding plate is about three times as durable as that of conventional products, which allows for a higher processing rate and longer lifetime.

Specifications

| Ion accelerating voltage | 2 to 8kV |

|---|---|

| Milling speed | 500μm/h or more |

| Max. specimen size | 11mm (W) x 10mm (L) x 2mm (T) |

| Specimen swing function | Automatic swing of specimen during milling by ± 30° |

| Auto start mode | The milling operation is automatically started once a preset pressure value is reached |

| Intermittent mode | Pulse-controlled ion beam irradiation reduces ion beam specimen exposure during milling |

| Finishing mode | Fine surface finish milling is automatically started once processing is completed |

Catalogue Download

IB-19530CP CROSS SECTION POLISHER(TM)

Related Products

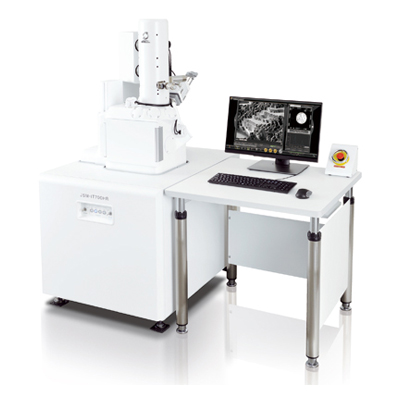

JSM-IT800 Schottky Field Emission Scanning Electron Microscope

The JSM-IT800 incorporates our "In-lens Schottky Plus field emission electron gun" for high resolution imaging to fast elemental mapping, and an innovative electron optical control system "Neo Engine", as well as a system of seamless GUI "SEM Center" for fast elemental mapping with a fully embedded JEOL energy dispersive X-ray spectrometer (EDS), as a common platform.

The JSM-IT800 allows for the replacement of the objective lens of the SEM as a module, offering different versions to satisfy various users requirements. With the JSM-IT800, five versions are available with different objective lenses: a hybrid lens version (HL), which is a general-purpose FE-SEM; a super hybrid lens version (SHL/SHLs, two versions with different functions), which enables higher resolution observation and analysis; and the newly-developed semi-in-lens version (i/is, two versions with different functions), which is suited for the observation of semiconductor devices.

Furthermore, the JSM-IT800 can also be equipped with a new Scintillator Backscattered Electron Detector (SBED) and a Versatile Backscattered Electron Detector (VBED). The SBED enables the acquisition of images with high responsiveness and produces sharp material contrast even at a low accelerating voltage, while the VBED can help obtain images of 3D, topography and material contrasts. Thus, the JSM-IT800 can help users to obtain information that was not obtainable and to solve problems in measurement.

IB-19520CCP CROSS SECTION POLISHER™

Thermal damage can be reduced by cooling the specimen with liquid nitrogen during processing.

Designed to suppress the consumption of liquid nitrogen, allowing long cooling periods.

Rapid cooling of the specimen while immersed in liquid nitrogen. Return to room temperature. Designed to allow parts to be detached.

Incorporates a mechanism to allow the process from polishing to observation to be performed without exposing the sample to the air.

JSM-IT700HR InTouchScope™ Scanning Electron Microscope

SEM- Essential in Daily Lab Operation JSM-IT700HR Makes it Easy.

Nano-scaled materials are driving the current technological breakthroughs and their observation and analysis is facilitated by a new and innovative SEM, JSM-IT700HR.

Its new electron gun with spatial resolution of 1 nm and the largest probe current of 300 nA, combined with an exceptionally userfriendly software interface significantly simplifies observation and analysis in SEM.

The compact instrument design also features a large specimen chamber with multiple accessory ports as well as EDS integration.

JSM-IT700HR Advanced SEM, Powerful and Simple to Use.

JSM-IT510 InTouchScope™ Scanning Electron Microscope

Easy to acquire data for all specimen types

Scanning electron microscopes (SEMs) are indispensable tools not only for research but also for quality assurance and manufacturing sites.

At those scenes, the same observation processes need to be performed repeatedly and there has been a need to improve the efficiency of the process.

With the JSM-IT510, the newly added Simple SEM function allows users to "leave the manual repetitive operation to it", required for SEM observation, making SEM observation more efficient and easier.

JCM-7000 NeoScope™ Benchtop SEM

Benchtop scanning electron microscopes are used in a wide range of fields, such as electrical, electronics, automobiles, machinery, chemical, and pharmaceutical industries. In addition, SEM applications are expanding to not only cover research and development, but also address quality control and product inspection at manufacturing sites. With this, demands for further improved work efficiency, much faster and easier operation, and a higher degree of analytical and measurement capabilities, are increasing.

The JCM-7000 Benchtop Scanning Electron Microscope is designed based on a key concept of "Easy-to-use SEM with seamless navigation and live analysis". The JCM-7000 incorporates three innovative functions; "Zeromag" for smooth transition from optical to SEM imaging, "Live Analysis" for finding constituent elements for an image observation area, and "Live 3D" for displaying a reconstructed live 3D image during SEM observation.

When you place the JCM-7000 next to an optical microscope, further-faster and more-detailed foreign material analysis and quality control can be made.

More Info

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.