JSX-1000S

X-ray fluorescence

spectrometer (XRF)

The JSX-1000S is an X-ray fluorescence spectrometer that provides quick, easy elemental analysis using touch screen operation. It is equipped with functions for conventional qualitative and quantitative analysis (FP method, calibration curve method), as well as screening for RoHS elements. With a variety of both hardware and software options available, it is customizable to cover a wide range of analysis needs.

Features

JSX-1000S in motion

Click the "replay" button in the box above, and the movie will start(for 4 minutes)

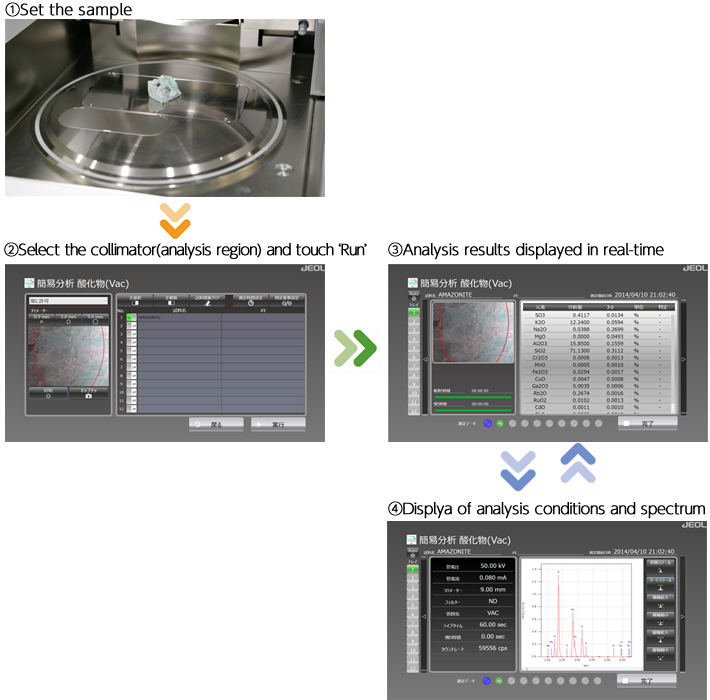

Simple Operation

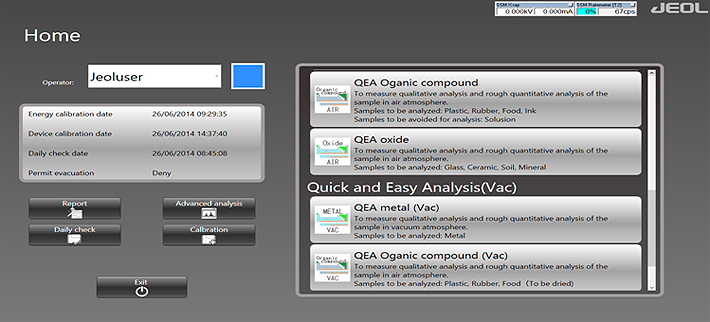

Simply set the sample and touch the screen; that’s how easy it is to operate. Another touch of the screen is all it takes to switch between analysis results and spectrum display. It is as easy to operate as a tablet PC or a smart phone. (Operation using a keyboard and a mouse is also supported.)

Set & Touch simple operation

A simple, intuitive operation GUI

High Sensitivity & High Throughput

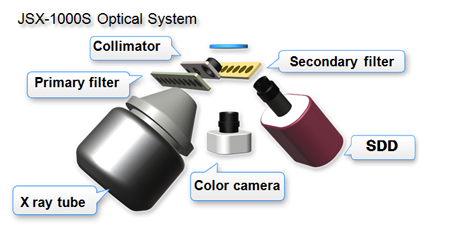

JEOL’s own SDD (silicon drift detector) and newly-developed optical system, in combination with filters designed to handle the entire energy range, make it possible to achieve high-sensitivity analysis.

The sample chamber vacuum unit (option) further increases detection sensitivity for lighter elements.

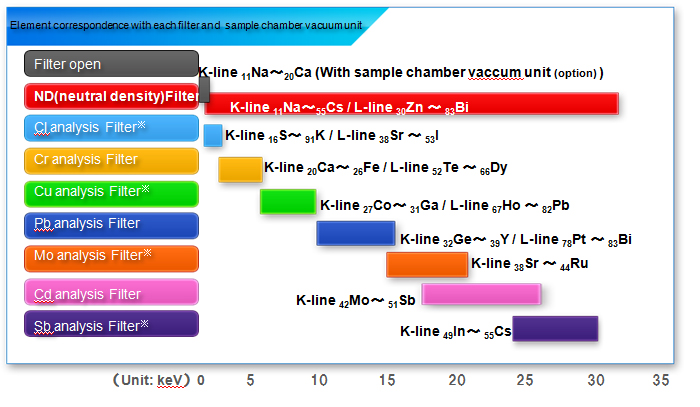

Sensitive analysis throughout the entire energy range

High-sensitivity analysis can be performed across the entire energy range using a maximum of 9 types of filters and a sample chamber vacuum unit.

Cl, Cu, Mo and Sb are options

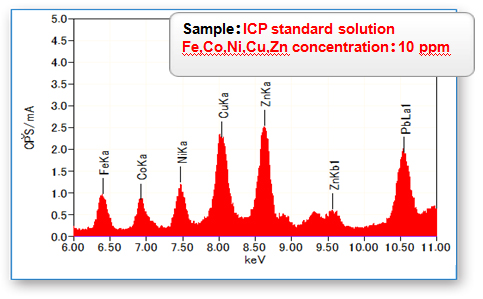

Example: trace element detection (10 ppm or less)

Providing Solutions

With solution based applications, the desired analysis can be executed automatically according to pre-recorded recipes. Simply select the desired solution icon from the solution application list for automated analysis and display of results. Solution applications offer simplified analysis in a wide range of fields.

The new Smart FP (Fundamental Parameter) method makes it possible to obtain highly-accurate quantitative results without the need to prepare a standard sample, and includes automatic correction for thickness and residual ingredient balance.

(The residual balance correction and thickness correction functions are only applicable to organic samples.)

| Thickness | Crrection | Cr | Zn | Cd | Pb | Automatic balance |

|---|---|---|---|---|---|---|

| 0.5mm | No | 0.008 | 0.037 | 0.001 | 0.002 | 99.76 |

| 3.8mm | 0.012 | 0.109 | 0.004 | 0.006 | 99.64 | |

| 0.5mm | Yes | 0.011 | 0.137 | 0.015 | 0.010 | 99.54 |

| 3.8mm | 0.011 | 0.134 | 0.016 | 0.011 | 99.55 | |

| Standard value | 0.010 | 0.125 | 0.014 | 0.010 | ||

Specifications

| Analysis element range | Mg to U |

|---|---|

| F to U (Option) | |

| X-ray generator | 5 to 50 kV, 1 mA |

| Target | Rh |

| Primary filter: 9 types, Automatic exchange | Standard:OPEN, ND, Cr, Pb, Cd |

| Option:Cl, Cu, Mo, Sb | |

| Collimator: 3 types, Automatic exchange | 0.9mm, 2mm, 9mm |

| Detector | Silicon drift detector (SDD) |

| Specimen chamber size | 300mm(D)×80mm(H) |

| Specimen chamber atmosphere | AIR / VAC (Option) |

| Chamber observation mechanism | Color camera |

| Operation computer | Windows ® Desktop PC with touch panel |

| Analysis software (Standard) | Qualitative analysis (Automatic, KLM marker, Sum peak display, Spectrum search)

Quantitative analysis (Bulk FP method, Calibration curve method) RoHS analysis solution (Cd, Pb,Cr, Br, Hg) Simplified analysis solution Report creation software |

| Software for daily check (Standard) | Tube bulb aging, Energy check, Intensity check |

Windows® is either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Major options

SAMPLE CHAMBER VACCUM UNIT

AUTO SAMPLE CHANGER

FILTER SET

FILTER FP METHOD ANALYSIS SOFTWARE

THIN FILM FP METHOD ANALYSIS SOFTWARE

SUM PEAK REMOVAL SOFTWARE

Ni plating screening solution

Sn plating screening solution

Halogen screening solution

Related information

Application

Application JSX-1000S

Film Thickness by Thin Film FP Method

Quantitative and Qualitative Analysis of Inorganic Elements in Plastic by FP Method

Quantitative Analysis of Oxides using the FP Method

Qualitative and Quantitative Analysis of Metal Alloys by FP Method

Analysis with separation of As and Pb in Iron and Steel is possible.

Analysis of Cracks in Brass Piping Parts

Test /Analysis of Foreign Substances on Resin surface by X-ray analysis

Gallery

More Info

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.