3D Printing of Copper: Technical Challenges and Solutions

Copper is used in various fields such as heat exchangers and power lines due to

their superior physical properties. By using 3D printers for additive manufacturing of copper, it is now

possible to produce complex shapes that were not achievable with traditional processing methods, which has

recently attracted significant attention.

This column provides an easy-to understand explanation on manufacturing of copper using 3D printers.

1. The reason why 3D printing of copper is attracting attention

Copper is an essential material in the modern industry, because of its physical properties such as high

thermal conductivities, high electric conductivities, and excellent ductility. For example, heat exchangers

use copper pipes for internal piping to obtain high heat exchange efficiency. Also, copper is used for

patterns of printed circuit boards and power cables as they have excellent electric conductivities.

In addition, recently, as represented by SDGs, the idea of giving importance on sustainability of businesses

has been spreading. Therefore, it is considered that 3D printers play active parts. Many companies and

research institutes are paying attention to the additive manufacturing for copper as they think that 3D

printer will help make heat exchangers and electrical conductivity more efficient. 3D printers can make

shape freely. It is possible to obtain a shape that was not possible before with conventional processing

methods such as machining, cutting and pressing. For example, many companies are considering the possibility

of producing more efficient motors by producing hair-pin parts in coils which are used in electric vehicles

by using 3D printers. If the efficiency of motors improves, the cruising distance of electric vehicles will

improve. In addition, the capability of highly efficient use of energy will lead to a reduction of carbon

dioxide emitted from thermal power station. This can be the exact approach to sustainable businesses that

are outlined in the SDGs. The same applies to heat exchangers. Emergence of highly efficient products

utilizing free shapes result in the reduction of primary energy, leading to a realization of industries that

are environmentally-friendly.

2. Types of 3D printers that can manufacture copper

The types of 3D printers that can use copper or copper alloys as raw material powders are categorized below.

- Powder Bed Fusion (PBF) methods (laser beam/electron beam)

- Directed Energy Deposition (DED) method

- Fused Deposition Modeling (FDM) method

- Binder jet method

The features of each printing method are explained in the column below. Please refer to it.

Generally, for printing copper, 3D printers applying the powder bed method are mostly employed. For copper alloys, laser-based powder bed fusion (LB-PBF), which utilizes a fiber laser as the heat source, is predominantly adopted. In contrast, pure copper absorbs only approximately 5% of the laser energy within the relevant wavelength range of fiber lasers, resulting in limited processing efficiency. Consequently, electron beam powder bed fusion (EB-PBF), which uses an electron beam as the heat source, tends to be employed for the 3D print of pure copper.

3. Comparison of copper material for 3D printers

3-1. Comparison of pure copper and copper alloy

| Comparison items | Pure copper | Copper alloys |

|---|---|---|

| Electrical conductivity | High (second highest after silver) | High, but lower than pure copper |

| Thermal conductivity | High (second highest after silver) | High, but lower than pure copper |

| Mechanical strength | Low | Mostly higher than pure copper |

| Heat-resistance | Relatively low | Mostly higher than pure copper |

| Printing by 3D printers | Difficult (printing by electron beam and high power laser beam, green or blue laser is required. | Mostly easily printed |

The copper materials used with metal 3D printers are largely divided into "pure copper" and "copper alloy". Each has its own characteristics, and a material that is suitable for the purpose is chosen.

Pure copper has extremely high electrical and thermal conductivity, making it suitable for high-current applications such as busbars and electrodes, as well as heat sinks that require excellent heat dissipation. For these applications, it is required to efficiently pass electricity or heat, so the nature of pure copper is utilized. However, the strength of pure copper tend to decline in high temperature and oxidization advances when the temperature exceeds about 300℃. So, attention is needed for use in a high temperature. In addition, printing by the laser beam method is difficult and the electron beam method is better for reliable printing. On the other hand, copper alloys have improved mechanical strength and heat-resistance compared to pure copper and they are suitable for parts to be used in high-temperature environments or parts requiring abrasion resistance. For example, CuCrZr alloys tend to maintain strength at high temperatures and are used for rocket nozzles and automotive engine parts. Cu-Ni alloys have high anti-oxidization and are often used for sea environment. Copper alloys do not have as much thermal conductivity nor electrical conductivity as pure copper, but are used in a wide range of applications due to the improvement of strength and heat-resistance. Copper alloys are easier to fabricate than pure copper when production by 3D printers is considered.

3-2. Comparison of powder and wire materials

| Comparison items | Powder | Wire |

|---|---|---|

| Main printing method | Powder bed method DED method | DED method |

| Printing accuracy | High | Slightly low |

| Printing speed | Relatively slow | Fast |

| Material management | Appropriate dust measures and maintenance of dry environment are necessary. | Measures against oxidation and humidity is required, but management as strict as powders is not necessary. |

| Material losses | A certain amount of unused powder is left | Little or no unused material remains. |

When categorized by the shape of materials, "powder" and "wire" are typical.

The copper powders are used with the powder bed fusion method, DED method, and binder jet method. In

particular, when used in powder bed fusion, they are characterized by the ability to produce high-density

parts with fine and complex geometries. Powder materials can secure uniform product quality and can optimize

the features of pure copper and copper alloy. However, the printing speed is slightly slow and handling and

managing the powders can be difficult. Moreover, re-use and storage of powders need attention and

environment management and safety measures are also required.

On the other hand, wire materials are used with the DED method. In particular, when it is printed by arc

discharge as a heat source, it is called wire arc additive manufacturing (WAAM).

When wires are used, printing speed is faster than that for powder materials and so it is suitable for

production of large parts and for repair works. The material supply of wires is stable and wires offer

excellent cost performance. When printing of large parts and quick production is needed, it is a great

advantage. Other than these, there is a method called fused deposition modeling (FDM) which uses filament

mixed with copper particles as raw materials.

4. Issues and solution for 3D printing of copper

Printing of copper materials using metal 3D printers has several issues. Here, three issues are addressed and their solutions by the laser method and electron beam method are shown.

Issue 1: High reflection rate of pure copper

Pure copper has a high reflection rate at the surface, melting with the commonly used fiber laser is

difficult due to its low energy absorption rate.

To resolve this issue, three approaches are introduced: "change the laser wavelength" "increase laser

power", and "use of the electron beam method".

・Change laser wavelength

The laser absorption rate of copper changes greatly due to wavelength.

The absorption rate of an infrared laser is 5% or so, but both the green laser and blue laser of short

wavelength have high energy absorption rate, promoting melting.

However, it is difficult to obtain high power with a green laser or blue laser.

There are not many models of 3D printers using them.

・Increase laser power

By increasing the laser power and increasing energy density, melting of copper locally is possible even for cases when most of lasers are reflected.

・Use of the electron beam method

Because energy conversion efficiency of an electron beam is as high as 80% or higher, it is more suitable than a laser to mold pure copper. Pure copper has high thermal conductivity and even if it melts, it cools and solidifies quickly, making it difficult to achieve high density with a laser. In contrast, the electron beam method has high power and efficiency and it is a hot process with pre-heating, high density molding is possible.

Issue 2: Quality deterioration by oxidization

Copper easily reacts with oxygen and when copper oxide is produced during printing, mechanical strength and electrical conductivity decrease. Countermeasures for oxidization during printing with laser beam method, are to print under an inert gas environment such as argon and nitrogen and to use powder material after surface treatment.

On the other hand, electron beam method performs printing in vacuum and it can minimize the impact of oxidization.

Issue 3: Curving and cracking due to residual stress

The residual stress means the stresses remaining inside of materials after the removal of external force.

When printing a metal by 3D printer, the material expands and contracts by repeating heating and cooling.

During this process, even if one part cools and tries to contract earlier, the surrounding areas prevent

this movement, resulting in internal tensile and compressive forces. This is the residual stress.

When residual stress accumulates in a printed product, it will cause a curve and crack.

The resolution measures to reduce deformation by residual stress include reducing the temperature gap between melting and cooling stages through pre-heating. Another approach is to control overall deformation by designing the shape of the printing target, adjusting the printing angle, and determining how to attach support materials. Additionally, the local anisotropy of residual stress can be utilized by adjusting the scanning direction of the lasers.

Reference:

School of Fundamental Science and Engineering, Waseda University.

"Reduction of the thermal distortion caused by the fabrication process of metal additive

manufacturing".

Waseda University.2022-10-17.

https://www.waseda.jp/top/news/84340

In the electron beam method, the entire powder bed surface can be preheated by rapidly scanning with a high-power electron beam. As a result, residual stress inside the printed parts can be mitigated, reducing distortion and cracking.

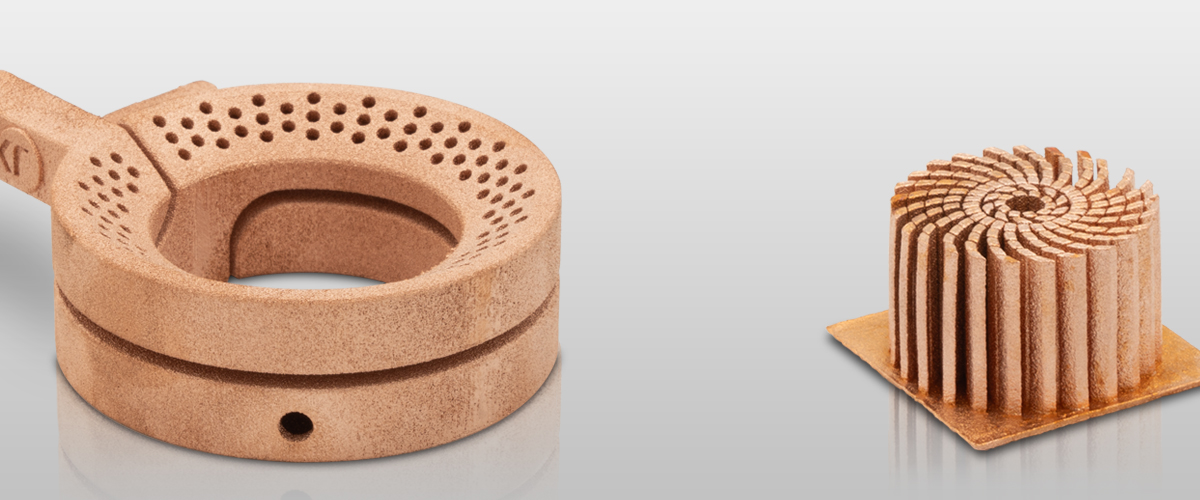

5. Example of 3D printing for copper

Here is the introduction case of NDK Inc. who sticks to pure copper instead of copper alloys and introduced the electron beam method metal 3D printer.

NDK Inc.~Metal 3D Printer supporting advancement of induction hardening technology

NDK Inc. has a long proven history in the field of induction hardening technology and is aiming for

further advancement by adopting metal additive manufacturing technology.

In this interview, we asked NDK in detail about how NDK introduced the metal 3D printer, its future

perspective, and its expectations for JEOL Ltd.

6. Conclusion

Copper is utilized in a wide range of fields due to its excellent characteristics. Recently, copper parts printed by metal 3D printers began to be used. However, the printing of copper has many technical issues and an appropriate printing method and selection of material shape are needed.

Each of methods: laser beam method and electron beam method has its own advantages. It is recommended to consider the difference between pure copper and copper alloy, powder and wire materials and select the optimal printing method.

Related products

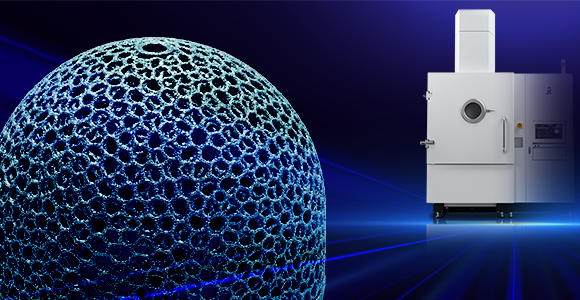

JAM-5200EBM Electron Beam Metal 3D Printer

We have developed the "JAM-5200EBM", an electron beam powder fusion (EB-PBF) metal 3D printer, by

applying the electron beam technology we have cultivated in electron microscopes and electron beam

lithography systems for semiconductor production.

The powder bed fusion method can produce a mold with higher density and strength compared to other metal

3D printer methods, and can mold complex shapes with high precision. The JAM-5200EBM does not require

the introduction of inert gas during molding, is equipped with a long-life cathode, and uses

high-definition automatic beam correction technology to ensure highly reproducible production. The

JAM-5200EBM is capable of molding high-melting-point metals and pure copper, which are difficult to mold

with laser printers.

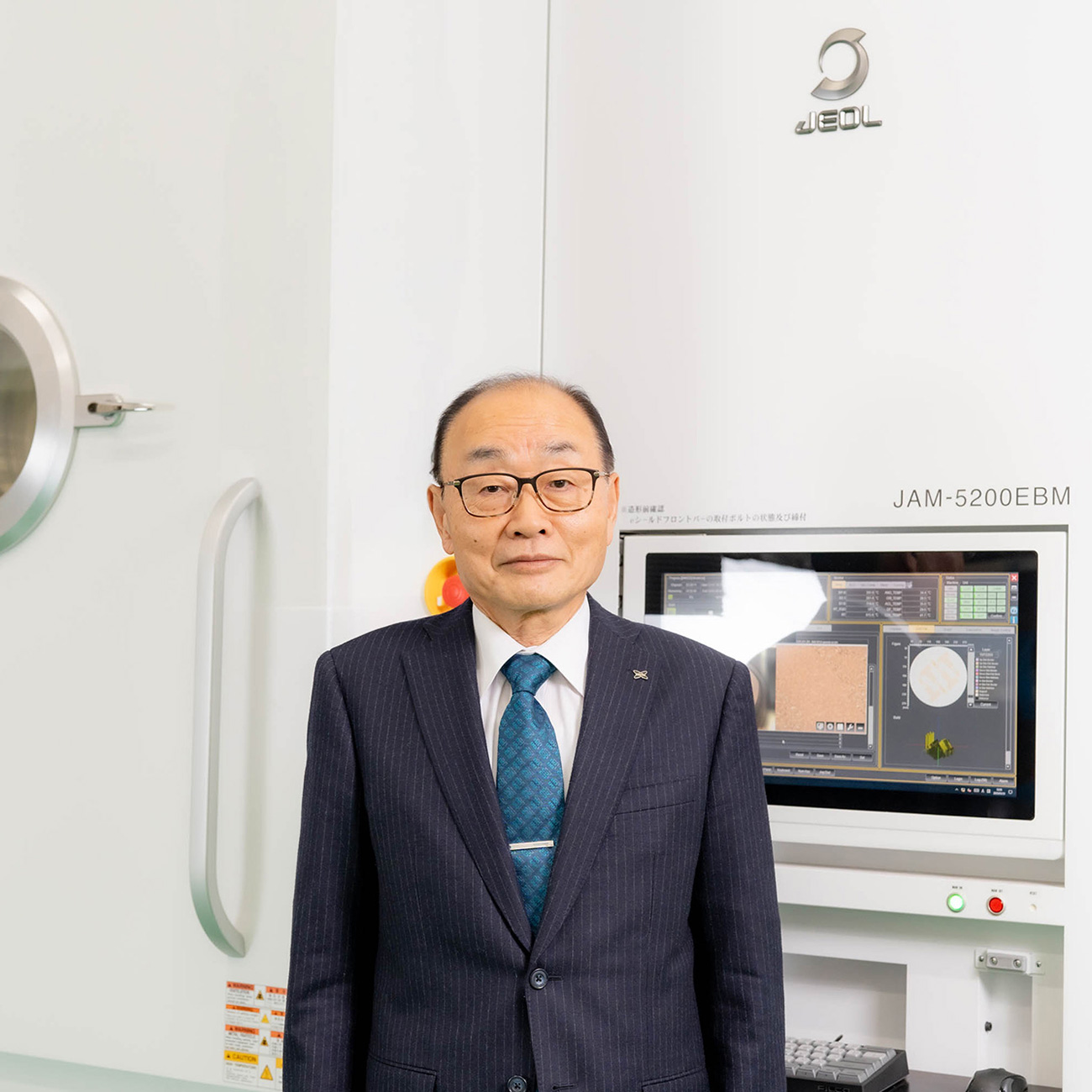

Development secrets

The JAM-5200EBM Development Trajectory - The future of electron beam metal 3D printers

This report introduces the development background, difficulties, and the hope and future prospects of the product by interviewing the member of the development team including the project leader of Hironobu Manabe.

JEOL Ltd.

Since its foundation in 1949, JEOL has been committed to the development

of cutting-edge scientific and metrology instruments, industrial and medical equipment.

Today,

many of our products are used throughout the world and we are highly regarded as a truly global

company.

Aiming to be a 'top niche company that supports science and technology around the

world', we will continue to respond precisely to the increasingly sophisticated and diverse needs

of our customers.