What is a metal 3D printer? : A Comprehensive Guide to the Differences and Features of Each Method

Compared to conventional metalworking methods, metal 3D printers can fabricate complex shapes and have various other advantages such as reduced material loss and shorter construction periods, and their practical application is expanding. In this column, we will explain in detail the fundamental mechanism of metal 3D printers and their main manufacturing methods.

What is a metal 3D printer (additive manufacturing machine)?

A metal 3D printer is a device to mold a 3D shape by melting metal powders or metal wires as material with a laser or electron beam, and layering them one layer at a time, according to 3D CAD data. The metal working methods include cutting, casting, forging, sheet metal working, pressing, powder metallurgy, and bonding. The metal 3D printer can be called a new machine tool.

History of Metal 3D printers

The development of metal 3D printer goes back to 1980s. In 1987, Chuck Hull in the U.S.A. developed the first commercial 3D printer "SLA-1" by using stereolithography. This method uses resin as a material. Then, a technique to melt metal powders with a laser was developed, and in 1990s, a commercial metal 3D printer appeared. After the State of the Union Address - made by President Obama in 2013, metal 3D printers began to attract attention worldwide. Projects for development were launched in the U.S.A., Europe, China, and other countries. Also in Japan, the Technology Research Association for Future Additive Manufacturing; TRAFAM was established in 2014 and various projects on 3D printers have been implemented including metal 3D printers.

Comparison of conventional metalworking methods and metal 3D printers

The process of building up layer by layer to create a 3D modeling object is called "Additive Manufacturing"(AM). AM has the following features compared to conventional metalworking methods.

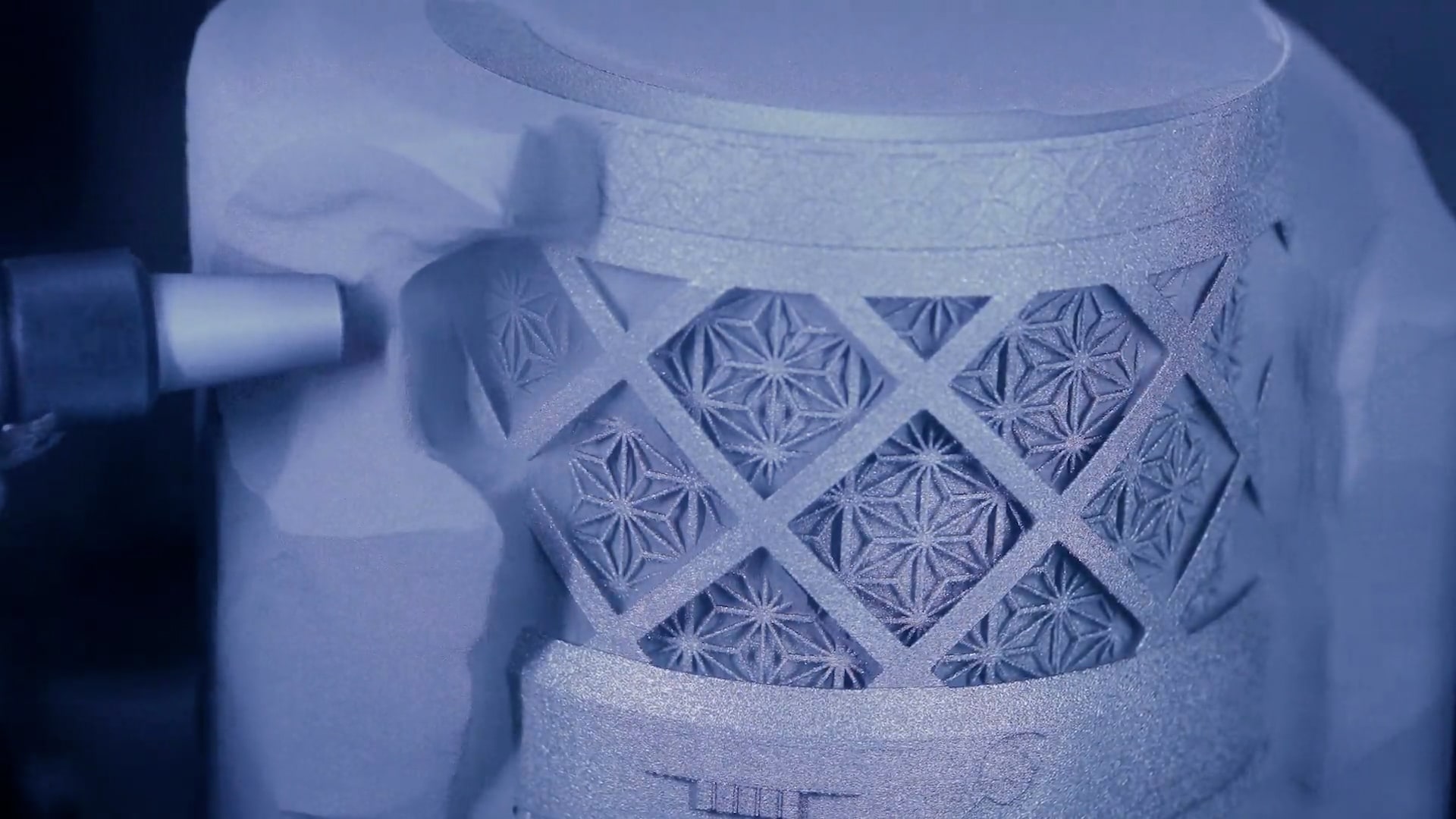

- Complex shapes can be fabricated such as mesh, lattice structures and hollow structures.

- Optimizing the structure enables weight reduction of parts while maintaining strength.

- By integrating multiple parts, the number of parts can be reduced, and welding, brazing, and fasteners can be eliminated. It also leads to a reduction in assembly work and a shorter construction period.

- Molds and jigs are not required, and there is no need to store molds.

- Compared to machining, there is less waste of materials.

- Production with a short lead time is possible, as production can start as soon as the 3D data and metal materials are available. As on-demand production is possible, there is no need to keep inventory, and production volume can be adjusted according to demand.

- Direct manufacturing from CAD data makes it suitable for prototyping, development, and customized manufacturing involving design changes.

- Production that does not rely on craftsmanship is possible thanks to digitalization. Metal 3D printers are one of the tools to realize DX.

As each of the conventional metalworking methods has advantages and disadvantages, the metal 3D printer has the issues below:

- There are limitations on the sizes, shapes, and metal materials for manufacturing. (This depends on the type of metal 3D printer and the model of the manufacturer).

- Not every shape can be molded with high accuracy. There are certain shapes and arrangements that are suitable for manufacturing.

- Machining and other processing are superior in terms of dimensional accuracy and surface roughness.

- The possibility is high not to obtain the cost advantages if mass production of products that can be manufactured by conventional methods is implemented. Costs of equipment and materials such as metal powders tend to be higher than those of conventional methods.

- Normally, post-processing is required. Removing supporting material (supporting part of the hollow part), heating treatment, blast processing, and surface polishing can be necessary, depending on the type of metal 3D printer and the model of the manufacturers.

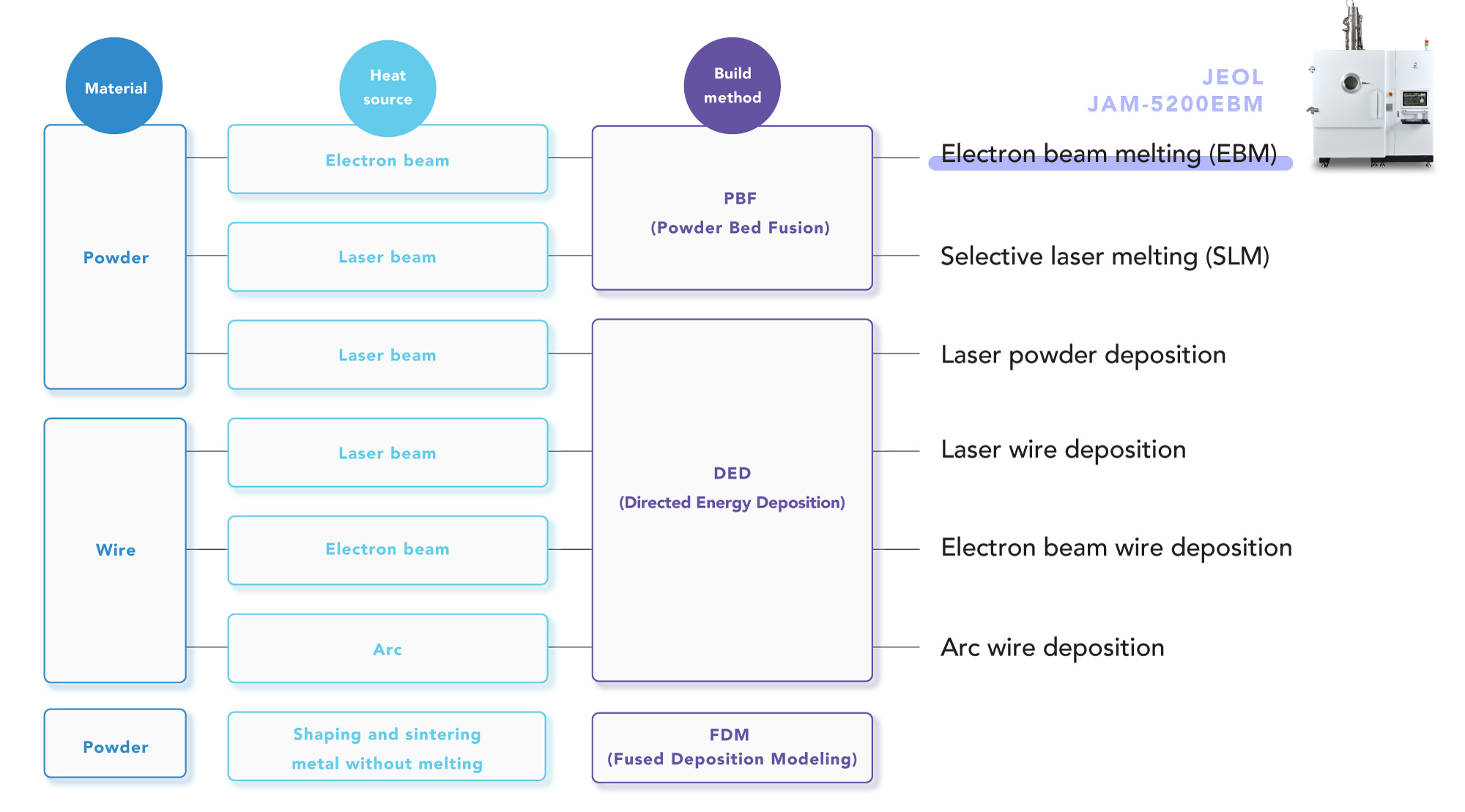

Types of Metal 3D printers (manufacturing method)

Metal 3D printers can be classified into several types according to their manufacturing methods. First, let's take a look at what types of methods are available and their characteristics.

1.PBF (Powder Bed Fusion)

The Powder Bed Fusion is the most mainstream method among metal 3D printers and is widely used around the world. The powder bed with metal powders evenly-spread is selectively scanned with a laser or electron beam of heat source. By repeating the melting and solidifying, the desired shape is molded by adding a layer at a time. Once the manufacturing is completed, the surrounding powders are removed, and the completed build is taken out. The removed powders are collected and reused for another manufacturing after sieving.

As the Powder Bed Fusion allows for manufacturing with higher accuracy and reproducibility than other methods and can produce parts of high density and strength, it has an excellent record in aerospace as well as medical fields.

The powder bed fusion has two types of heating sources, laser and electron beam. Each has its own characteristics, which are explained in detail in the next section.

【Major Manufacturers】

・Laser: EOS, 3D systems, Nikon SLM Solutions, Colibrium Additive (former Concept Laser), Matsuura Machinery Corporation, Sodick Co., Ltd.

・Electron Beam: Colibrium Additive(fomer Aram), Mitsubishi Electric Corporation, JEOL Ltd.

Comparison of laser and electron beam in Powder Bed Fusion

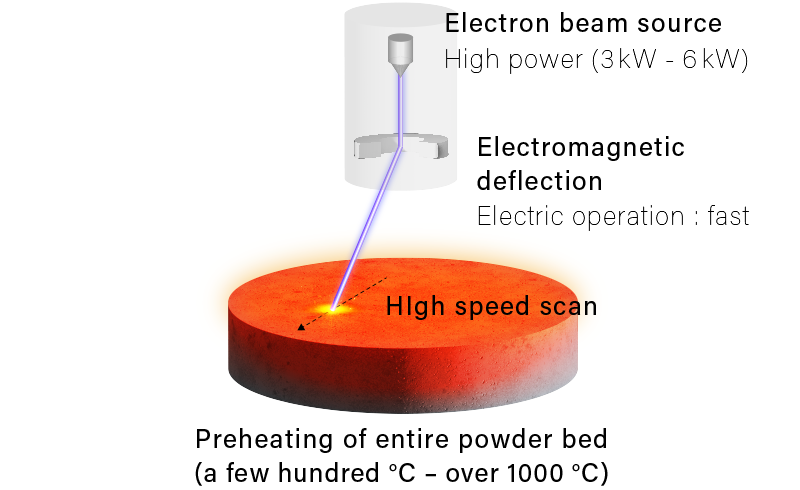

The Powder Bed Fusion described earlier uses metal powders for manufacturing by melting the powders. Lasers and electron beams are used as the heating source. The main differences are as follows:

| Laser Powder Bed Fusion | Electron Beam Powder Bed Fusion | |

|---|---|---|

| Maximum output | Typical fiber lasers range from 400 W to 1 kW. There are many instruments with more than one laser source. | 3kW to 6kW |

| Beam deflection | Mechanical (Galvanometer mirror-drive) | Electromagnetic deflection |

| Beam scan speed | Low speed (msec order) | High speed(μsec order) |

| Heat input efficiency | Largely depends on the metal material and laser type. Generally, 5-40% for common fiber lasers (65% for titanium). | 80% or better for almost all metal materials |

| Manufacturing atmosphere | Inactive gas | Vacuum |

| Pre-heating function | None or up to about 200°C | Available(up to about 1100°C) |

| Others | Mainstream in metal 3D printer. Wide variety of equipment models. Relatively compact equipment. | Vacuum chamber is required. |

The above are general comparisons. Specifications of laser systems vary widely depending on the output power and number of lasers installed, as well as the equipment manufacturer's model.

Now let's specifically look at the advantages and disadvantages of laser and electron beam methods.

Advantages of the laser powder bed fusion

First, we will discuss the advantages of the laser method.

The laser beam's high light-collecting ability allows for high-precision manufacturing of fine shapes and parts with complex internal structures. The surface after manufacturing is relatively smooth,reducing the need for post-processing, which is a positive feature of this method. The instruments can be relatively compact and space-saving compared to electron beam metal 3D printers, which is an advantage. Also, as this is widely used around the world, there are many materials with manufacturing records and examples of practical applications, which is a positive feature of this method.

Disadvantages of the laser powder bed fusion

One disadvantage is that it is difficult to preheat uniformly, so residual stress tends to accumulate. Depending on the metal material and shape, deformation or cracking may occur. Therefore, the heating processing is often performed after manufacturing to alleviate internal stress.

Also, since the output power is slightly lower than that of an electron beam source and the heat input efficiency is lower, the manufacturing speed is relatively slow. It inevitably takes longer to produce large parts or large quantities of parts. Multi-laser types with multiple lasers can produce large parts, but it takes several days to complete the process.

Advantages of electron beam powder bed fusion

Next, let's look at electron beam 3D metal printers.

The electron beam 3D printers can scan the entire surface of a powder bed at high speed with an electron beam before melting, and preheat it to several hundred to a thousand degree Celsius in a short time. As the hot process(electron beam pre-heating) can suppress residual stress, distortion and cracking of the build can be reduced. Another advantage is that it requires fewer supporting materials than the laser method. Electron beams have higher output power and thermal energy conversion efficiency than lasers, resulting in faster manufacturing speeds, which is an advantage when manufacturing large parts or mass-producing large batches at a time. In addition, with the electron beam method, manufacturing is performed in a vacuum, and the effects of oxygen and moisture can be suppressed, thus it is suitable for manufacturing active metals such as titanium alloy. It is also suitable for the materials with low absorption rates for fiber lasers. including high-melting-point metals such as tungsten and molybdenum, and pure copper.

Disadvantages of the electron beam powder bed fusion

On the other hand, electron beam metal printers also have their challenges.

First of all, the electron beam method requires blasting to remove the temporarily sintered powders after manufacturing because the powders around the build are lightly combined together during preheating. If the manufacturing object has internal channels or a complex interior, it is difficult to remove the temporarily sintered powders by blasting. So, this method is not good at manufacturing a mold with complicated water pipes.

Since the diameter of the metal powders used is greater than that of the laser method, the accuracy and surface roughness of the fine shape is slightly superior with the laser method.

In addition, compared to laser systems, there are not many equipment manufacturers, and the number of materials that have been molded is still limited. Future expansion of the material that can be used is expected.

2.DED (Directed Energy Deposition)

The DED (Directed Energy Deposition) is a manufacturing method to melt the metal powders and metal wires which are continuously supplied, with laser or electron beam or arc discharge energy, and to deposit them.

The manufacturing speed is faster than the other methods and larger parts can be molded, which is a positive feature.

On the other hand, the powder bed fusion is generally superior in terms of dimensional accuracy and surface roughness. As the shape to be molded is limited, this method is not good at manufacturing a fine part and a part of complicated shape.

As this method is to deposit materials from the nozzle like an overlay, it can add a shape on different types of metals or parts. It is widely used for repairing parts. Depending on the instrument, it is also possible to mold different types of metals during manufacturing by switching the metals to be supplied.

【Major Manufacturers】

・Laser(Powder):DMG MORI CO., Ltd. , NIDEC MACHINETOOL CORPORATION, Nikon Corporation, Shibaura Machine Co., Ltd.

・Laser (Wire): Mitsubishi Electric Corporation, Meltio

・Arc(Wire): WAAM3D Ltd.

・Electron Beam (Wire): Sciaky Inc., pro-beam

3.FDM (Fused Deposition Modeling)

This principle is the same as that of a general resin 3D printer. The manufacturing is to extrude materials, so it is also called the material extrusion (MEX) method. Filaments of metal powders mixed with a thermoplastic resin material as a binder (binding agent) are melted by heat and extruded through a nozzle to form layers. After forming, the filaments undergo a degreasing process to remove the binder and are then sintered in a furnace. Since the volume shrinks by approximately 20% during sintering, the manufacturing must be done in a size that allows for this shrinkage. Material losses are low and the metal powders are easy to handle. Compared to other methods, it is inexpensive and easy to operate, making it suitable for prototyping and small-lot production, but it has some issues with density.

【Major Manufacturer】

Stratasys, Nano Dimension Ltd. (former Desktop Metal Inc. )

4.Binder Jetting

The spread metal powders are solidified layer by layer while a liquid binder is selectively sprayed through a nozzle. Similar to the FDM, the binder is removed during the degreasing process and the build is sintered in a furnace. During sintering, the volume shrinks by about 20%. This method does not require a heat source of high temperature during manufacturing or the support material. Similar to the powder bed fusion, the unused metal powders can be reused. With its high throughput, it is likely to be suitable for mass production. However, its density and strength are lower than that of the powder bed fusion. These are the challenges when applying to practical parts. This method is mainly good at manufacturing of small parts with fine shapes.

【Major Manufacturer】

Nano Dimension (former Desktop Metal Inc.), Markforged (former Digital Metal), Hewlett Packard

Other than these, there are methods such as the supersonic deposition method (metal powders are sprayed at high speed through a nozzle to bond metal particles) and the liquid metal deposition method (a metal version of the inkjet method. A suspension of metal particles is sprayed and bonded at high temperatures for deposition).

Metal 3D printer parts

There are several types of metals that can be processed with a metal 3D printer.Depending on the field -- such as aerospace, energy, electronics, or medical devices -- materials are selected based on the specific properties required for each application.In this section, we introduce the key characteristics and application examples of representative metal 3D printing materials.

Copper 3D printing

3D Printing of Copper: Technical Challenges and Solutions

By using 3D printers for additive manufacturing of copper, it is now possible to produce complex shapes that were not achievable with traditional processing methods, which has recently attracted significant attention.

This column provides an easy-to understand explanation on manufacturing of copper using 3D printers.

Titanium alloy 3D printing

Printing Titanium Alloys with Metal 3D Printer|Explanation of the Difference and Utilization of Laser/Electron Beam

In this column, we will explain the basic knowledge of titanium alloy 3D printing, the difference between LB-PBF and EB-PBF, and examples of utilization in an easy-to-understand manner.

JEOL JAM-5200EBM Features and Specifications

Finally, we will introduce JEOL's JAM-5200EBM, a metal 3D printer of the electron beam powder bed fusion.

The JAM-5200EBM is equipped with a high power 6kW electron beam source to realize high production efficiency. Employing a long life cathode, the electron beam automatic correction function, and powder dispersal prevention system, the JAM-5200EBM ensures reproducible production with stable electron beam irradiation over a long period of time.

For those who are planning to introduce a metal 3D printer or wish to find the most suitable implementation approach for their needs, we invite you to contact us for a consultation.

Related products

JAM-5200EBM Electron Beam Metal 3D Printer

We have developed the "JAM-5200EBM", an electron beam powder fusion (EB-PBF) metal 3D printer, by applying the electron beam technology we have cultivated in electron microscopes and electron beam lithography systems for semiconductor production.

The powder bed fusion method can produce a mold with higher density and strength compared to other metal 3D printer methods, and can mold complex shapes with high precision. The JAM-5200EBM does not require the introduction of inert gas during molding, is equipped with a long-life cathode, and uses high-definition automatic beam correction technology to ensure highly reproducible production. The JAM-5200EBM is capable of molding high-melting-point metals and pure copper, which are difficult to mold with laser printers.

Development secrets

The JAM-5200EBM Development Trajectory - The future of electron beam metal 3D printers

This report introduces the development background, difficulties, and the hope and future prospects of the product by interviewing the member of the development team including the project leader of Hironobu Manabe.

JEOL Ltd.

Since its foundation in 1949, JEOL has been committed to the development of cutting-edge scientific and metrology instruments, industrial and medical equipment.

Today, many of our products are used throughout the world and we are highly regarded as a truly global company.

Aiming to be a 'top niche company that supports science and technology around the world', we will continue to respond precisely to the increasingly sophisticated and diverse needs of our customers.