resin embedding

resin embedding

Resin embedding is a method used to embed a specimen in a resin prior to specimen processing, such as cutting, fracturing and polishing. Even brittle specimens (e.g. porous materials, tablets) and soft materials which are easily deformed by stress (e.g. polymers, biological specimens) can be reinforced by the resin to suppress deformation due to the processing. Small-sized metal specimens or powder specimens can be molded into a size or shape suitable for the processing by embedding them in a resin.

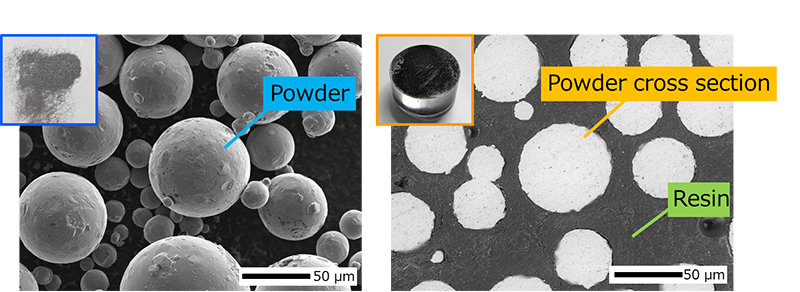

Fig. 1 shows an example of SEM images taken from Ti alloy powders used for a metal 3D printer, and from a cross section of the powders cut and polished after resin embedding. The SEM image of the cross section to the right shows no large voids and no impurities, confirming sufficiently high quality of the Ti alloy powders. It is difficult to cut and polish powders of a diameter of several 10 μm directly, but this example shows that the powders can be cut and polished by embedding the powders in the resin.

Fig. 1. Secondary electron image of Ti alloy powders (left) and Backscattered electron image of the cross section of the powders cut and polished after resin embedding (right).

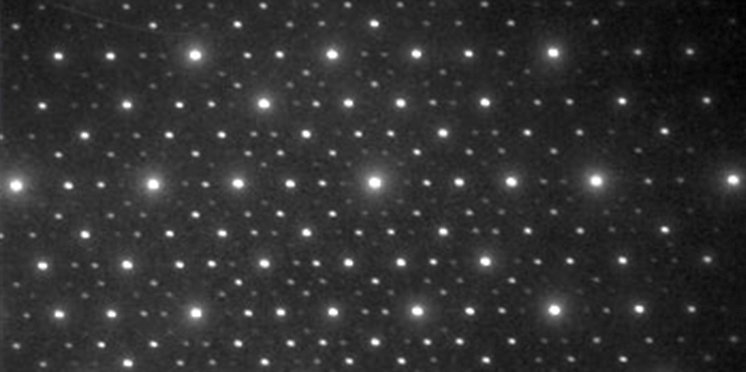

Fig. 2 illustrates the embedding procedure of a powder specimen in a cold resin. The resin is gently poured to a container housing the specimen until the resin entirely embeds the specimen. Then, using a vacuum debubbling machine, air bubbles are removed to attain close contact between the specimen and resin. After sufficient removal of air bubbles, the resin containing the specimen is left still to harden the resin firmly.

Fig. 2. General procedure of resin embedding

The specimen is embedded in the resin. Air bubbles are removed to get close contact between the specimen and resin. The resin containing the specimen is left still to harden the resin firmly.

Resins used for embedding in SEM are classified into four types depending on the hardening method; cold resin, heated and pressurized resin, thermohardening resin and light curing resin (Table 1). Since each resin has different characteristics, it is needed to choose a suitable resin according to the properties or shape of the specimen.

Table 1. Resins used to embed a specimen for SEM

1) The cold resin is the most basic resin because it hardens simply by leaving it still at room temperature though it requires half a day for hardening. During hardening, the cold resin warms up to about 40 °C due to reaction heat. The cold resin is used for all types of specimens, including small-sized metals or ceramics, powder specimens, brittle specimens (g. porous materials, tablets), composite materials, electronic circuit boards, and soft materials (e.g. polymers, biological specimens). The cold resin is recommended to use when trying resin embedding for the first time.

2) The heated and pressurized resin is used for specimens which do not deform by heat or pressure (e.g. metals, ceramics, minerals). It hardens in several minutes when a pressure of several MPa is applied at about 200 °C. Owing to its short hardening time, this resin enables specimen preparation in a short time. Thus, the heated and pressurized resin is suited to resin embedding of many specimens.

3) The thermo-hardening resin offers a good balance between a short hardening time and variety of specimens that can be applied to. Thus, this resin is most widely used as it has an intermediate characteristic between those of the cold resin and the heated and pressurized resin. That is, by applying a heat of about 100 °C, this resin hardens in several 10 minutes (much shorter than in the cold resin). However, plastic specimens and biological specimens cannot be embedded by this resin because they are deformed by heat. Porous materials are also unsuitable because this resin hardens before it reaches to the holes of the materials.

4) The light-hardening resin hardens in several minutes by irradiation of visible or ultraviolet light onto the resin. It hardens at room temperature like the cold resin. Thus, this resin is used for soft materials (e.g. polymers, biological specimens) which are deformed by heat or pressure. Like in the heated and pressurized resin, as the hardening time is short, specimens are prepared in a short time.

However, the specimens with a shape or color which doesnot allow light to reach this resin, are not possible to embed. The light-hardening resin is least frequently used among the four types of resins 1) to 4) due to the limited variety of applicable specimens.

When the resin-embedded specimens are observed and analyzed by SEM, attention should be paid to that the resin part can be charged and the elements originating from the resin may be detected.

Related Term(s)

Term(s) with "resin embedding" in the description

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.