silicon-drift detector

silicon-drift detector

The silicon-drift detector (SDD) is an EDS (energy dispersive X-ray spectroscopy) detector, which is composed of a detector element made of a silicon (Si) single crystal, a disc-shaped cathode, annular electrodes and a very small collector electrode (anode).

The detector is attached to an electron microscope and is used to identify constituent elements in a specimen by detecting the characteristic X-rays generated from the specimen with electron-beam irradiation onto it. Compared with the conventional Si(Li) detector (SSD), the SDD has enabled high-speed processing of electric signals and has achieved a high count rate of more than two orders of magnitudes (>105 cps). As a result, analysis speed of the constituent elements has become much faster than that of the SSD.

Furthermore, since the SDD is operated with Peltier cooling (not with liquid-nitrogen cooling), the detector is compact and light-weighted. Now the SDD is the mainstream of EDS detectors. The energy resolution of the SDD (128 to 135 eV for Mn Kα (5.9 eV)) is a little better than that of the Si(Li) detector (130 to 140 eV).

The measurement principle of the SDD and the Si(Li) detector is the same. That is, when characteristic X-rays are incident onto a Si single crystal, electron-hole pairs are generated. Electrons (charge Q) move to the anode and holes move to the cathode.

Then, a voltage V is generated between the cathode and the anode. By measuring the voltage, finally the constituent elements are identified.

In the Si(Li) detector, since the anode size is the same as that of the incident plane (cathode) of the X-rays, the capacitance C of the detector (condenser) is large. Thus, the ratio of the signal S (∝voltage V, V= Q/C) to the noise N (S/N ratio) is low. To improve the S/N ratio, thermal noise (main noise) has to be reduced by cooling the detector with liquid nitrogen and by a long signal acquisition time.

Thus, it is not practical to use a large Si(Li) detector with a size of 10 mm2 or more, because it requires a very long signal-acquisition time for improving the S/N ratio.

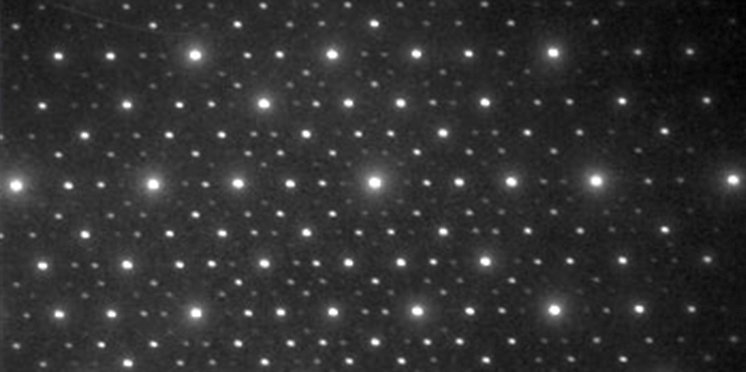

In the SDD, in order to decrease the capacitance C of the detector, the electrodes have a unique structure as shown in Fig. 1. A very small anode (ii) of 10-4 mm2 (width of ~10 µm) or less is placed at the center on the opposite side of the incident plane (cathode (i)), and the annular electrodes (iii) are surrounding the anode (ii). The electrons that reach the annular electrodes (iii) are collected to the anode by applying the voltage which increases stepwise from the outside to the inside to the annular electrodes.

Then, the capacitance C of the detector becomes small and the signal S becomes large. As a result, a sufficient S/N ratio is obtained even by Peltier cooling (about –several 10 °C) and even by a short signal acquisition time. The count rate of characteristic X-rays has greatly improved, more than two orders of magnitudes (>105 cps) compared with the Si(Li) detector. Finally, short-time elemental analysis is achieved. Furthermore, a large size detector can be manufactured for further improvement of the count rate because the SDD can maintain a high S/N ratio irrespective of the incident plane size thanks to the small anode. Nowadays, an SDD with an incident plane of 100 mm2 or more is developed for practical use.

Owing to the high speed of elemental analysis, SEM image observation with real-time elemental analysis or live elemental mapping is now being possible using a large probe current. Elemental analysis at low accelerating voltages using the SDD has also become possible at which the generation of characteristic X-rays is small.

Action of SDD

Fig. 1 shows the action of the SDD until characteristic X-rays enter the detector and finally the constituent elements are identified.

A negative potential is applied to the cathode (i) and a positive potential is to the anode (ii). Negative potentials to increase stepwise from the outside to the inside are applied to the annular electrodes (iii) so that the electrons reached them are collected to the anode (ii).

When the characteristic X-ray with an energy of hν (h: Planck’s constant, ν: frequency of the X-ray) is incident on Si, electron-hole pairs are generated in proportion to the X-ray energy. Since the energy needed to generate one electron-hole pair is 3.6 eV, one photon of Mn Kα (5.9 keV) creates approximately 1600 electron-hole pairs. The electrons in those electron-hole pairs move to both the anode (ii) and the annular electrodes (iii). The electrons which reached the annular electrodes are collected to the anode by the stepwise potential. On the other hand, the holes move to the cathode (i). A condenser with capacitance C is formed between the cathode (i) and the anode (ii). The voltage V across the condenser is measured. Then, the electric charge Q accumulated in the condenser is obtained using the relation V = Q/C. The number of the generated electrons is calculated by dividing the charge Q by the charge of one electron. Then, the energy of the characteristic X-ray is obtained from the number of the electrons generated by one photon. Finally, the constituent element is identified from the obtained X-ray energy. In the actual measurement, the X-ray energy is obtained from the measured voltage V by a calibration method using a standard specimen.

Fig. 1 Characteristic X-rays are incident onto the Si single crystal of the detector element from the left side.

① Electron-hole pairs are created.

② The electrons move to the anode (ii) and annular electrodes (iii) due to the difference in the potential applied between the cathode (i) and the anode (ii) + annular electrodes (iii). The electrons which reached the annular electrodes are collected to the anode (i) by a stepwise potential applied between the annular electrodes and the anode.

The holes move to the cathode (i). The voltage V, which is generated by the electric charge Q accumulated in the condenser of Si, is measured. The electric charge Q is obtained using the relation V = Q/C. The number of the electrons generated per one photon of the characteristic X-rays is calculated. Then, the energy of the characteristic X-rays is obtained and finally the constituent element is identified from the energy.

Term(s) with "silicon-drift detector" in the description

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.