segregation

segregation

A phenomenon where a part of the constituent elements in a material (metals, ceramics, high polymers, etc.) aggregates unevenly. In the case of a metal, segregation often occurs at a cooling process after a heat treatment or at an aging treatment. Segregation affects the mechanical strength and electrical properties of materials.

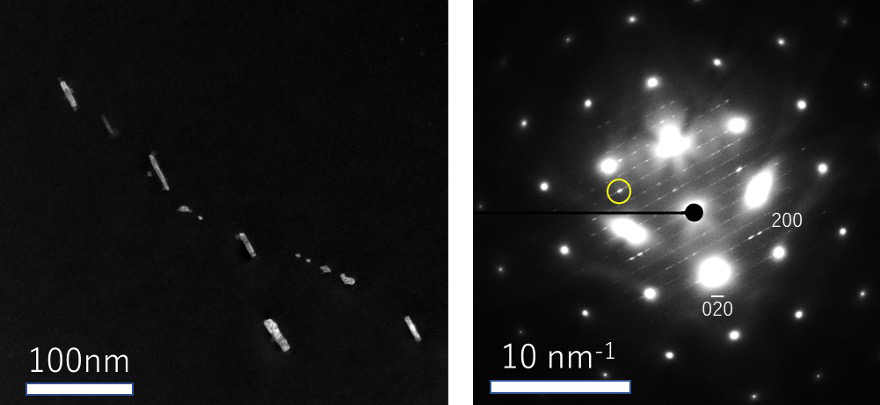

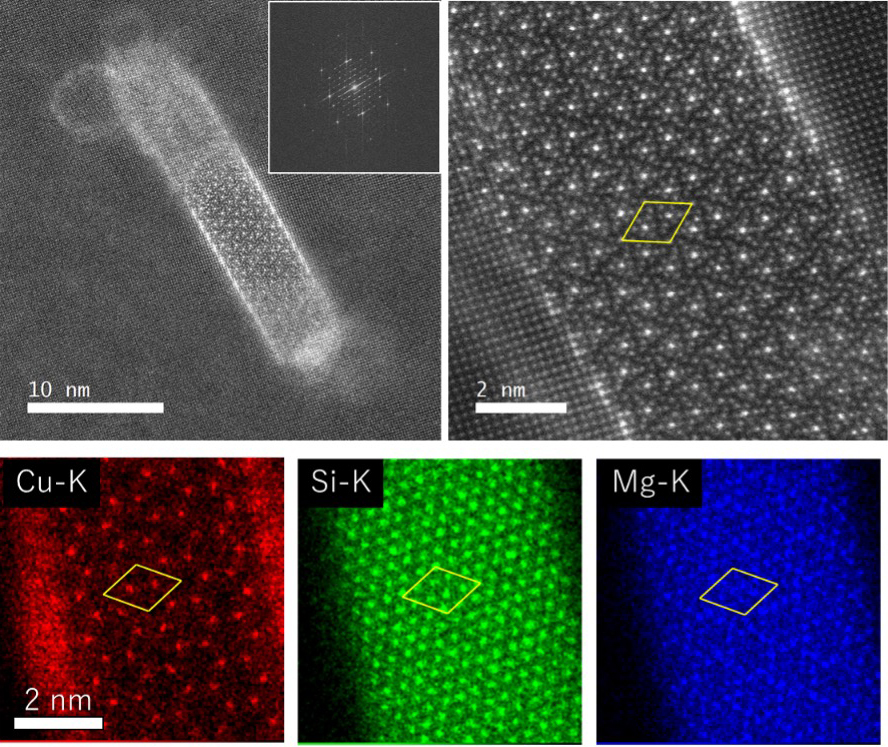

Figs 1 and 2 show an example of the segregation (Q' phase) of an Al-Mg-Si-Cu alloy analyzed by a TEM dark-field image, a selected-area diffraction (SAD) pattern, HAADF-STEM mages and EDS elemental-mapping images. In the TEM dark-field image, the distribution of the precipitates is visualized by selecting a diffraction spot originated from the precipitates. In the SAD pattern, the reflections originated from segregation are identified. The strong spots seen in the pattern correspond to the reflections from Al in the matrix phase while the weak spots around the strong spots correspond to the reflections due to the segregation of the added elements. In the HAADF-STEM images, the structure of the Q' phase is directly seen. From the EDS elemental-mapping images, the distribution of the added elements of Si, Mg and Cu are revealed.

Fig. 1 TEM dark-field image (left) of an Al-Mg-Si-Cu alloy (taken from a spot indicated by a yellow circle in the right electron diffraction pattern) and the selected-area diffraction (SAD) pattern (right). The distribution state of the segregation is revealed.

Accelerating voltage: 200 kV, [001] incidence.

Fig. 2 (Top) HAADF-STEM images of the Q' phase of an Al-Mg-Si-Cu alloy (left: whole image and the FFT pattern, right: partially enlarged).

(Bottom) EDS elemental-mapping images (elemental distribution of Cu (red), Si (green) and Mg (blue), from left to right).

Instrument for taking images: JEM-ARM200F. Instrument for thin-film preparation: JIB-4700F.

Related Term(s)

Term(s) with "segregation" in the description

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.