Lithium Ion Battery

The liquid-based lithium-ion batteries currently in use are referred to as

"LIBs."

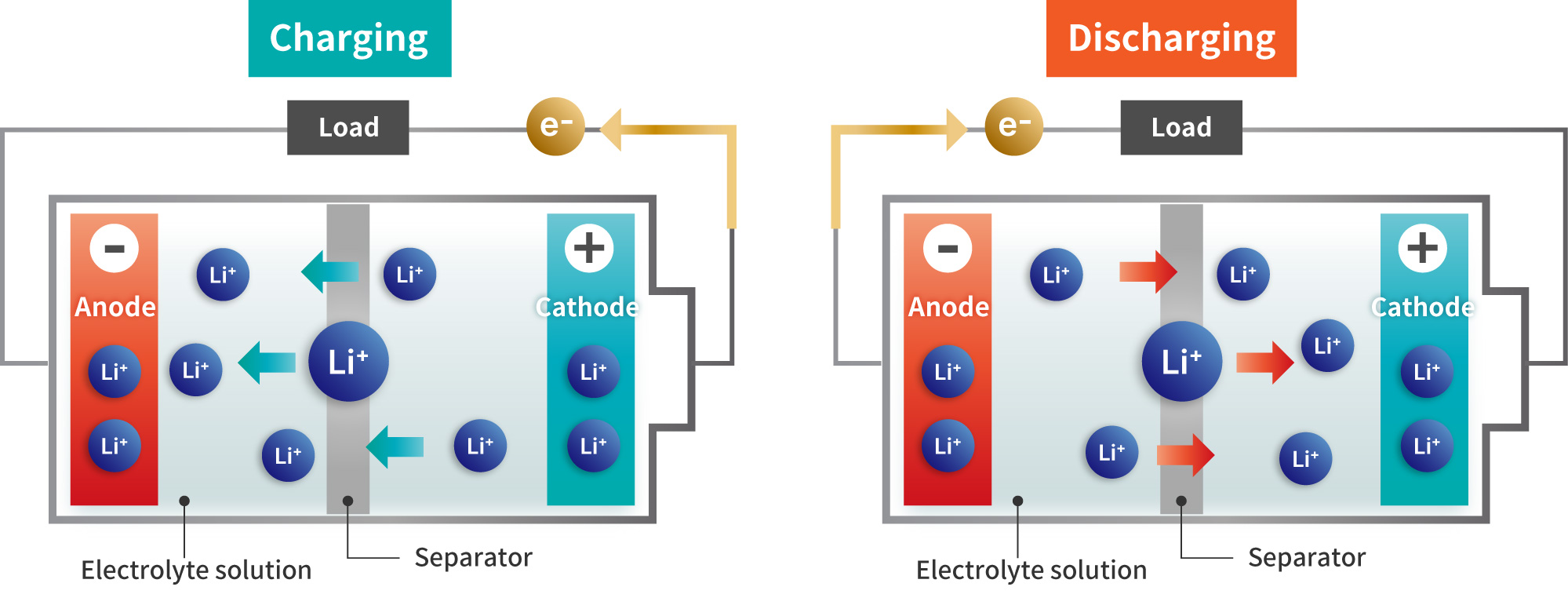

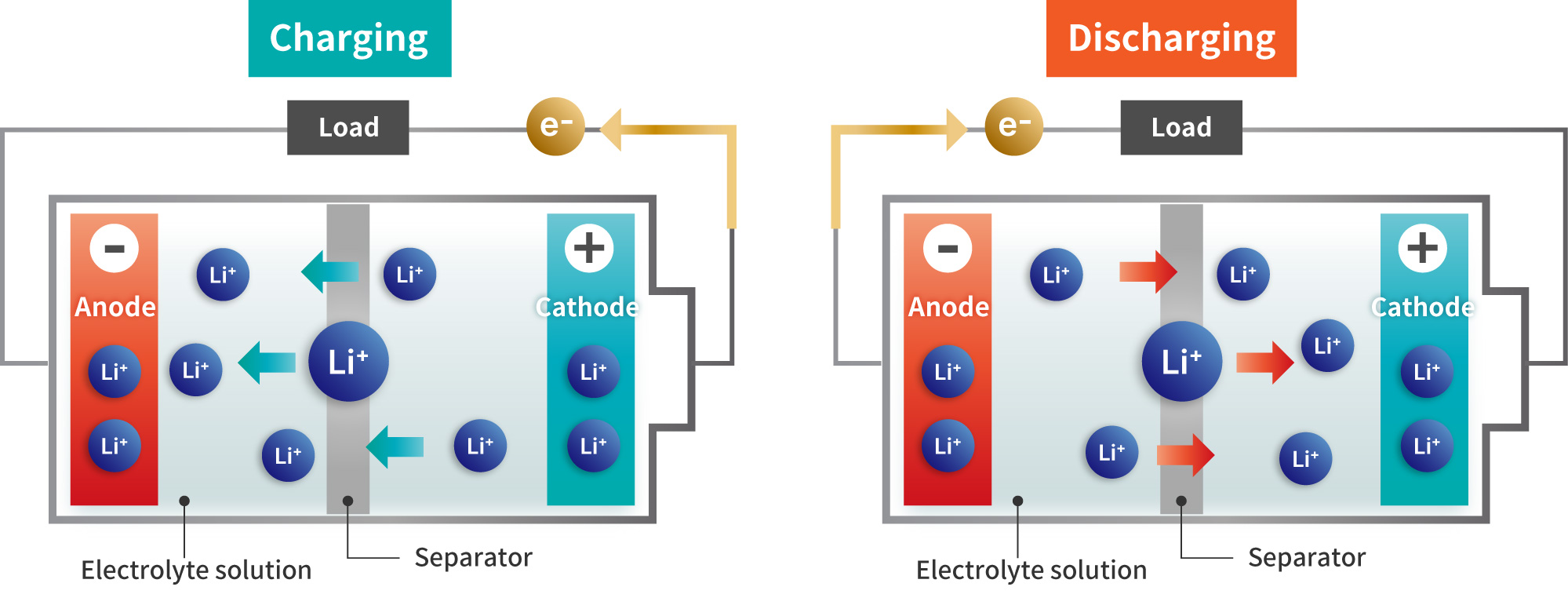

LIBs charge and discharge by moving lithium ions between the cathode and anode through an

electrolyte solution.

A polymer separator is placed between the cathode and anode to prevent short circuits, and an

organic solvent-based electrolyte is used to facilitate ion conduction.

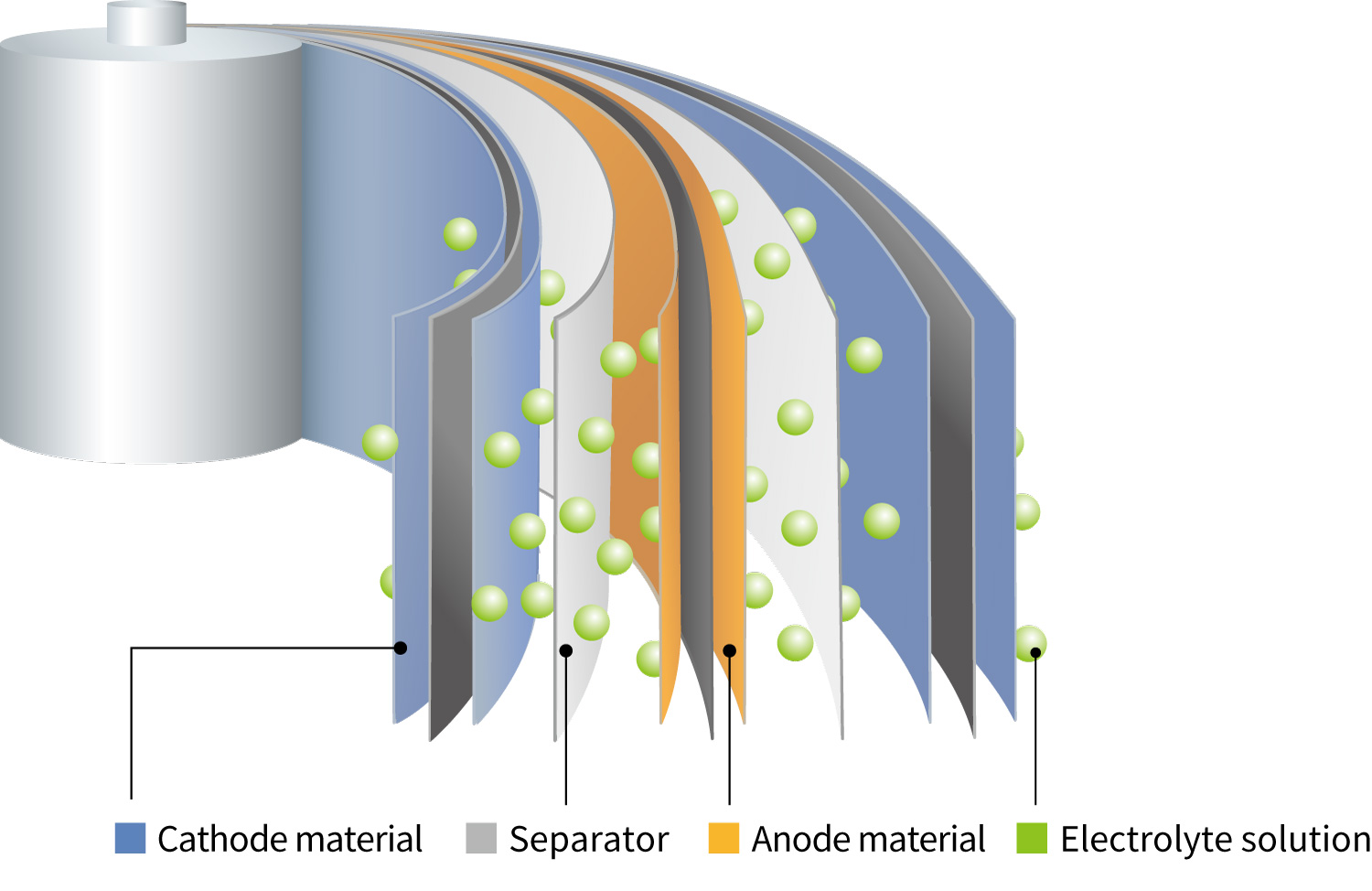

Composition and Shape of Lithium Ion Battery (LIB)

The basic structure of LIBs consists of components shown in the

figure on the right.

For the cathode, composite oxides containing lithium are used as the main active

materials. These are produced by mixing carbon materials as conductive additives with

polymer binders.

For the anode, graphite carbon capable of intercalating lithium is used and is similarly

prepared using polymer binders.

Separator films for LIBs are made of porous polymers with fine pores.

These separators serve a safety function by closing their pores in the event of thermal

runaway, thereby preventing short circuits caused by contact between the cathode and

anode.

The electrolyte solution is prepared by dissolving lithium-containing electrolytes in an

organic solvent.

For both the cathode and anode, electrode sheets are prepared by coating the respective active

materials onto a metal current collector foil.

The main battery formats are cylindrical, prismatic (rectangular), and pouch (laminated)

types.

In cylindrical and prismatic batteries, a separator is placed between the cathode and anode

sheets, which are then wound together using the winding method to form the cell.

In pouch-type batteries, in addition to the winding method, the stacking method is also used, in

which the cathode sheet, separator, and anode sheet are layered sequentially.

Cylindrical battery

Rectangular battery

Laminated battery

Since the materials used contain highly reactive lithium, manufacturing must be conducted in an

air-isolated environment, such as a dry room.

Similarly, material analysis requires specimen preparation, observation, and analysis to be

performed under air-isolated conditions.

Therefore, air-isolated instruments and integrated systems that connect them are highly

effective for the analysis of lithium-ion batteries.

Lithium Ion Battery Note

The applications of lithium-ion batteries are expanding from mobile phones and PCs to automobiles and large energy storage systems, requiring higher performance (output, stability, etc...) and safety. Various evaluation instruments are required to improve the performance and quality of lithium-ion batteries. This LIB note introduces the features and application functions of each instrument for the material evaluation of lithium-ion batteries.

Cathode

Cathode Materials:

Active

Components in Lithium-Ion Rechargeable Batteries

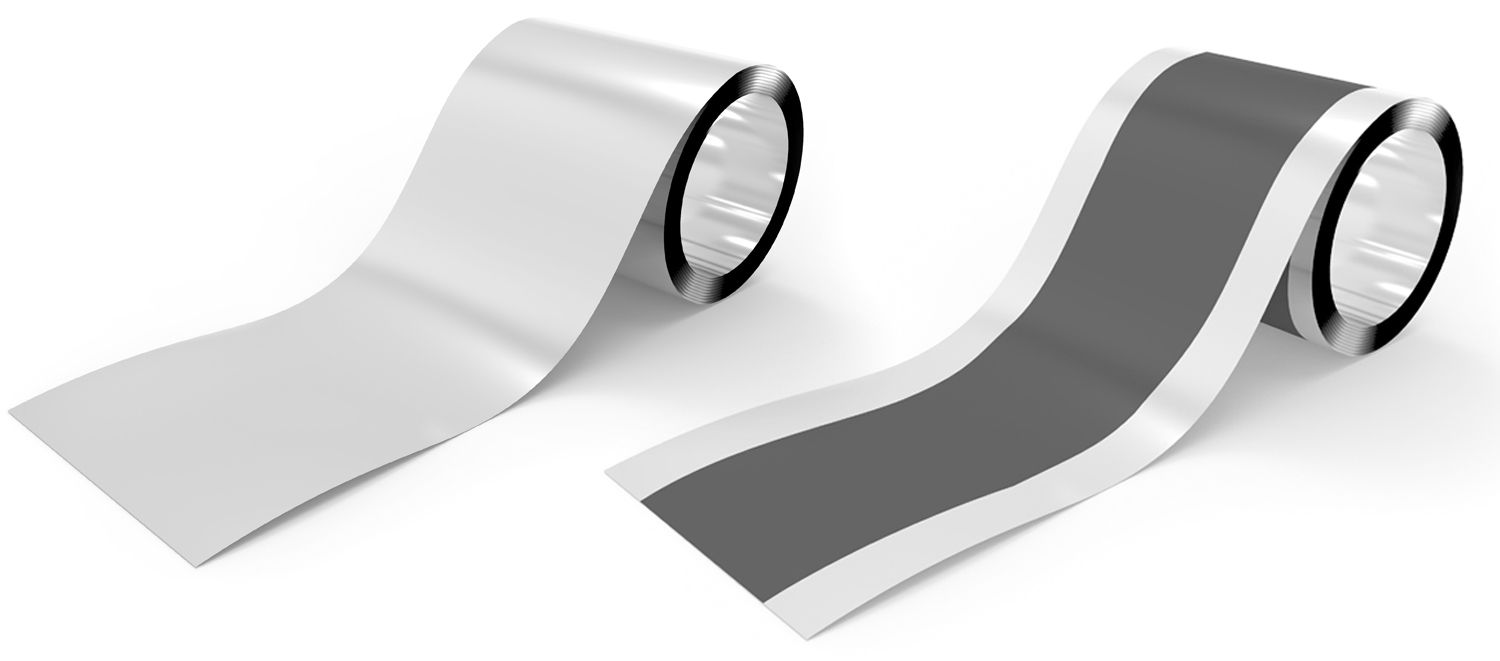

Aluminum foil (left) and Aluminum foil with cathode material (right)

The cathode of a typical lithium-ion battery consists of a current

collector, cathode active material, conductive additive, and binder.

Aluminum foil is used as the current collector, and a slurry made by dissolving and

kneading the cathode active material, conductive additive, and binder in a solution is

coated onto it.

The figure on the left shows the aluminum foil current collector before the cathode

material is applied.

The figure on the right shows the aluminum foil after the cathode material has been

coated, where the black region in the center represents the applied electrode material.

Cathode material powder (left)

Cathode material NMC811

SEM image(right)

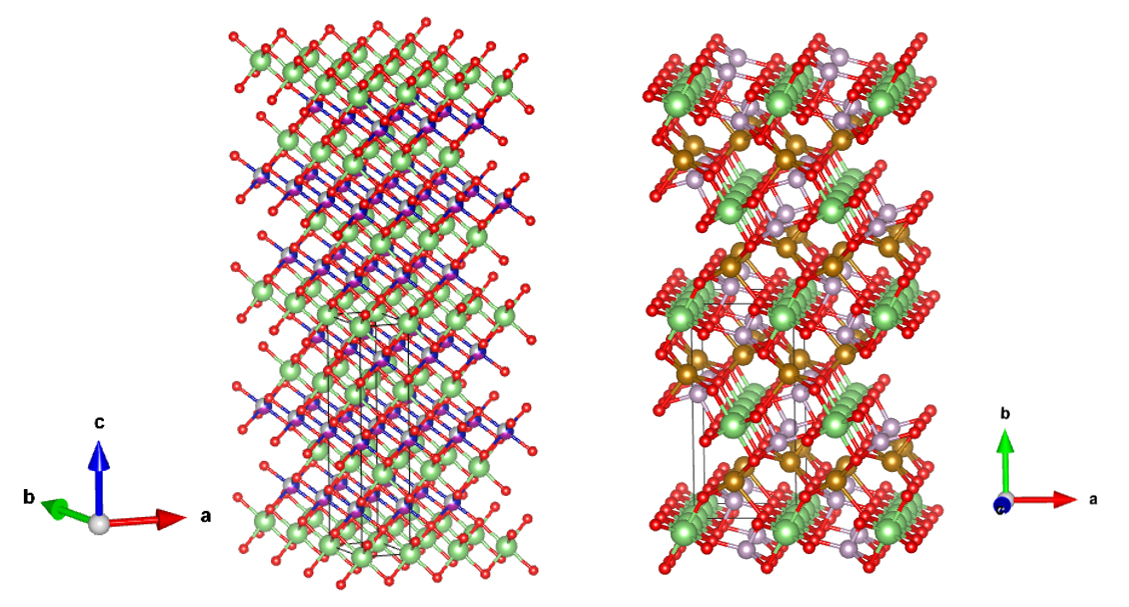

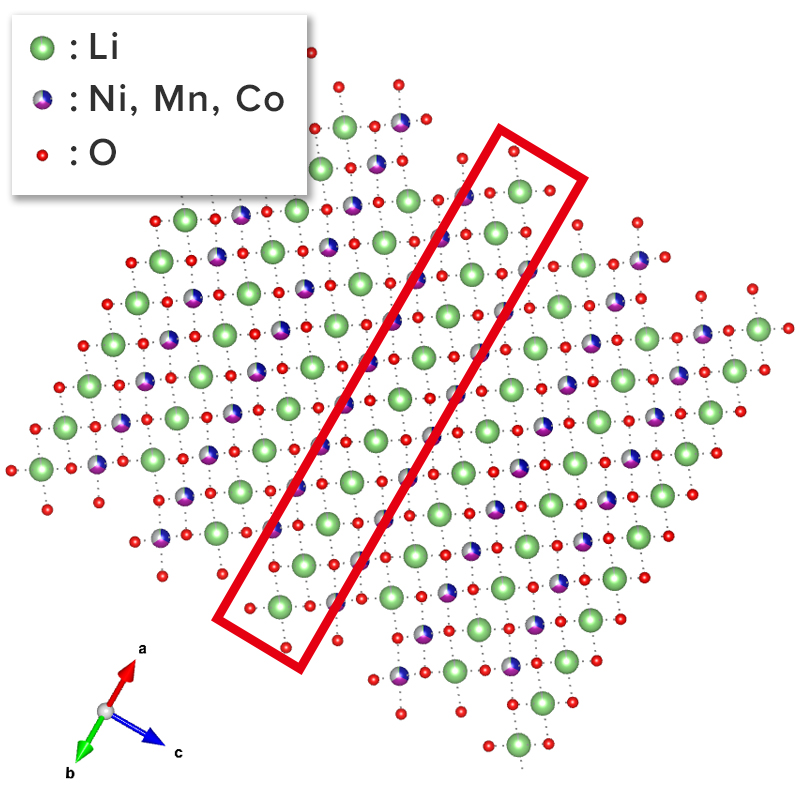

Transition metal oxides containing lithium are used as cathode active materials.

Common materials include lithium cobalt oxide (LCO), and ternary cathode materials such

as NMC

(Li(Ni1/3Mn1/3Co1/3)O2),

where part of the cobalt is replaced with nickel and manganese. The name "NMC" comes

from the initials of the transition metals: Ni, Mn, and Co.

Another common material is NCA, composed of nickel, cobalt, and aluminum. These

materials are widely used in batteries for electric vehicles, including automobiles.

In addition, LFP (LiFePO4), which uses lithium iron phosphate as the cathode

active material, is frequently employed. Iron phosphate-based materials are known for

their high safety due to their stable crystal structure, which is resistant to collapse

even under internal heating. This minimizes the risk of thermal runaway, making them

highly suitable for automotive applications.

Moreover, since iron is less expensive than other transition metals, LFP offers

advantages in terms of production cost.

Crystal structure of cathode material

NMC/NCA Layered

Rock Salt Structure (left)

LFP Olivine Structure (right)

refer to :

J.Appl.Cryst.(2011).44,1272-1276

Each cathode active material has a theoretical capacity, which represents the amount of

electric charge corresponding to the lithium content.

However, full optimization to achieve the maximum capacity has not yet been

realized.

Development efforts are underway to create cathode materials with even higher

capacity.

In research and development, substituted versions of transition metals and materials

with modified lithium content are being actively investigated.

For evaluation during R&D, various analyses are required in addition to basic battery

performance--such as the stability of the crystal structure during lithium insertion and

extraction reactions, and the thickness and composition of surface coating layers.

| Cathode material | Average voltage [V] | Theoretical Capacity [mAh/g] | Actual Capacity [mAh/g] | Cycle characteristics | Feature |

|---|---|---|---|---|---|

| LiCoO2 | 3.7 | 274 | 148 | 500~1,000 | Expensive raw material/Relatively low thermal stability |

| NMC | 3.6 | 280 | 160 | 1,000~2,000 | Potential changes are gradual |

| NCA | 3.6 | 279 | 199 | 500~1,000 | High energy density/Relatively tolerant to low temperatures |

| LiFePO4 | 3.2 | 170 | 165 | 1,000~2,000 | Less expensive raw material/Flat potential change/Relatively high stability |

Cathode current collector foil

Aluminum foil is considered the ideal material for the cathode current collector, as it holds

the cathode active material and facilitates the transfer of electrons to enable current

flow.

It is highly conductive, corrosion-resistant, and remains unaffected by lithium-ion doping.

Its surface is naturally covered with an oxide layer, and during charging, a more

corrosion-resistant aluminum fluoride (AlF3) layer forms, allowing the cathode to

support high electric currents.

Analysis example of cathode

material

Structural

evaluation of

cathode active material

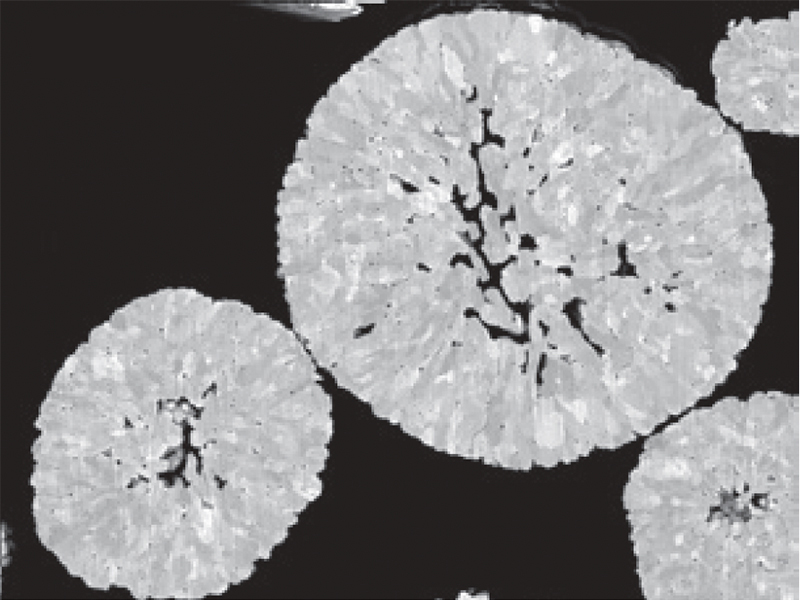

SEM Image of cathode particle cross section

Cathode active materials consist of spherical secondary

particles, which are formed by sintering smaller primary particles.

The size of the primary particles varies depending on the material, typically

ranging from several tens to several hundreds of nanometers.

During charging, lithium is extracted from the lithium-containing cathode active

material.

During discharging, lithium ions are expected to return to their original

positions within the crystal lattice.

However, due to factors such as overcharging, the lithium ions may not fully

return, resulting in structural changes.

Evaluating these structural changes is essential for understanding the

mechanisms and extent of battery performance degradation.

For structural analysis, local changes are examined using Transmission Electron

Microscopy (TEM), in addition to assessing the average structure using X-ray

Diffraction (XRD) and Raman spectroscopy.

The following examples demonstrate how crystal structure changes can be

evaluated using Raman analysis integrated with a Scanning Electron Microscope

(SEM), as well as electron diffraction and atomic-resolution imaging of specific

regions using TEM.

Another case shows the use of solid-state Nuclear Magnetic Resonance (NMR) to

analyze lithium behavior during charge and discharge cycles.

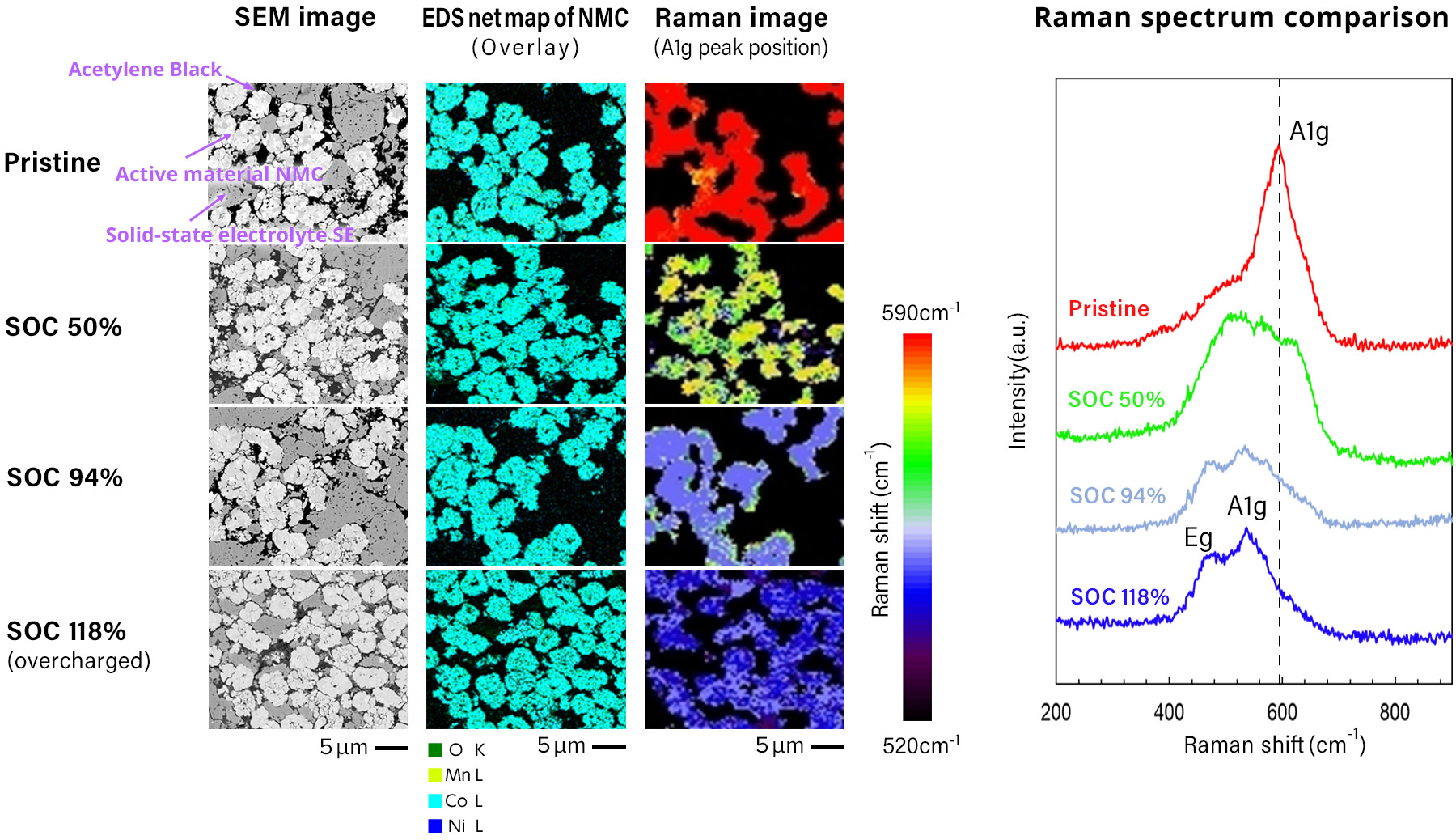

The figure below shows an example of analyzing structural changes in the cathode active

material at different states of charge using a Raman spectrometer integrated into a SEM,

as part of a combined SEM-EDS-Raman system.

The Raman spectra capture structural changes in the cathode active material at four

stages: uncharged, 50% state of charge (SOC), 100% SOC, and overcharged.

These changes are not detectable by EDS alone.

Raman spectroscopy reveals shifts in wavelength--referred to as Raman Shifts--relative to

the laser light, corresponding to changes in the longitudinal and transverse vibrational

modes between oxygen atoms in the crystal lattice as lithium is extracted during

charging.

These spectral shifts reflect alterations in the crystal structure that occur due to

variations in lithium content.

Sample courtesy:

Prof. Atsunori Matsuda

Department of Electrical and Electronic Information Engineering

Toyohashi University of Technology

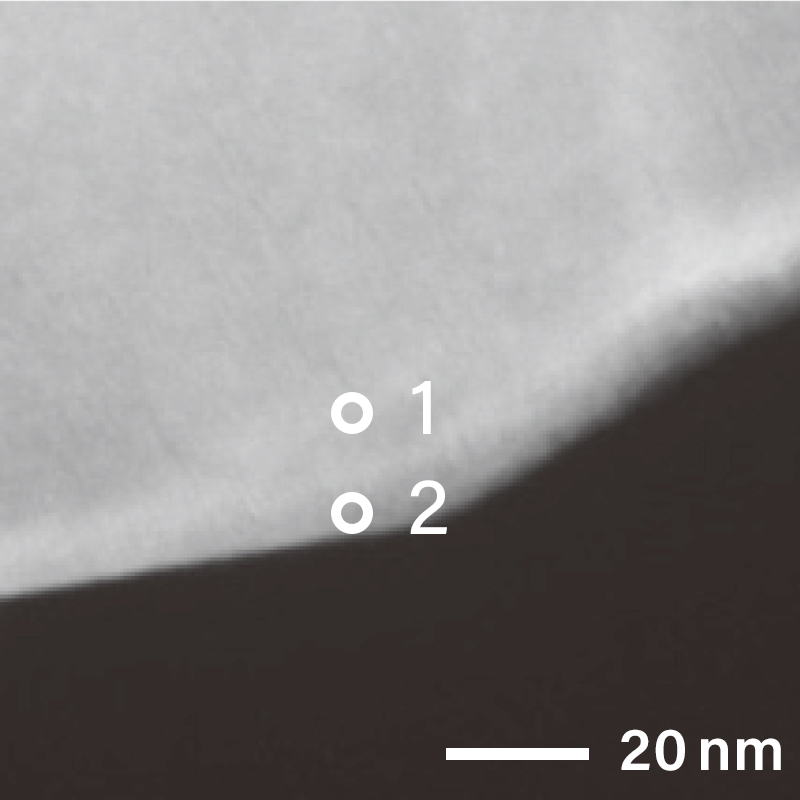

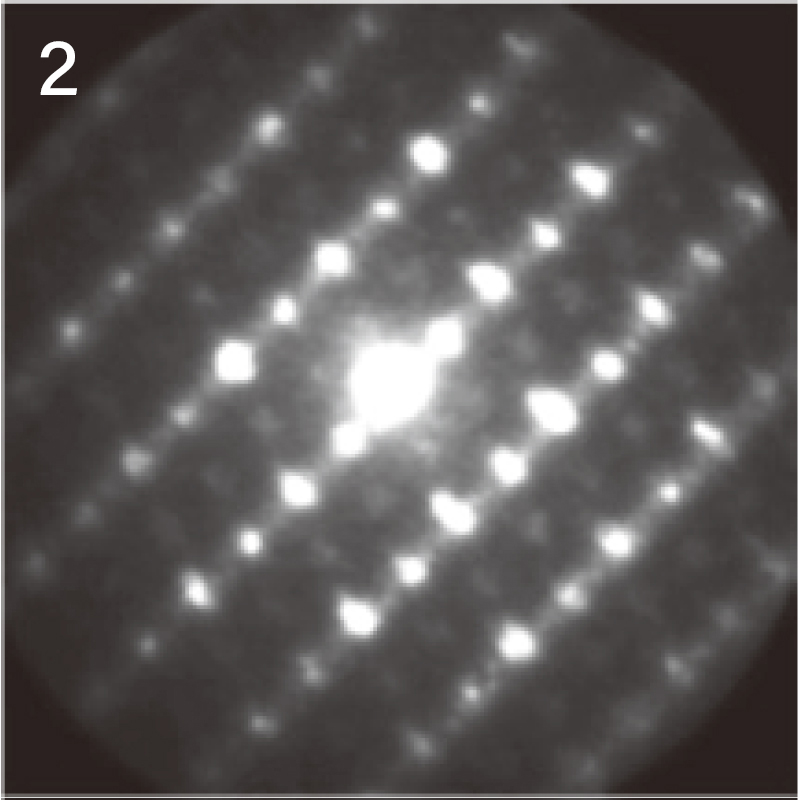

The figure below shows the electron diffraction pattern near the surface of a cathode

material particle obtained using a Transmission Electron Microscope (TEM).

Different electron diffraction patterns were observed at the surface and interior of the

cathode particle, indicating that their crystal structures are different.

For localized electron diffraction, Nano Beam Electron Diffraction (NBD) is

employed.

Using the NBD method, the diffraction pattern at analysis position "1" (inside the

particle) was identified as corresponding to the [11-20] zone axis of a layered

rock-salt structure.

In contrast, at analysis position "2" (surface), a different diffraction pattern was

observed, suggesting a structural transformation near the particle surface.

NBD patterns obtained from the surface and inside of the particle

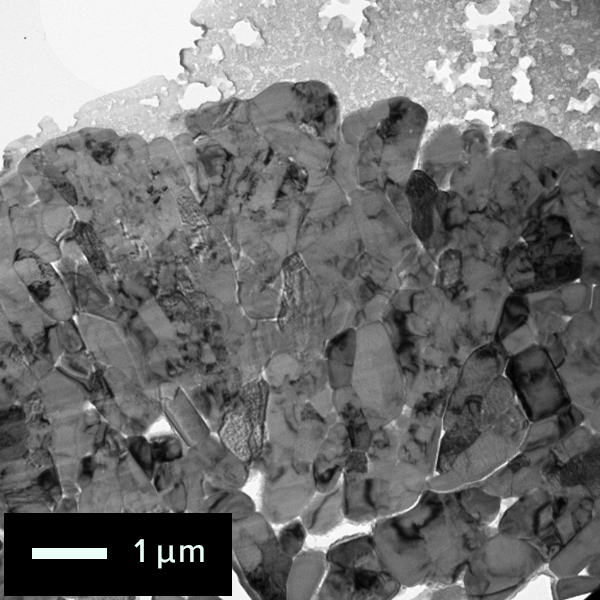

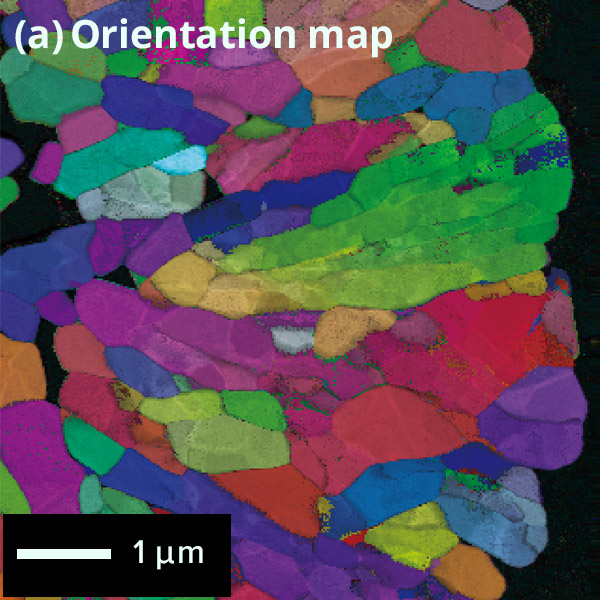

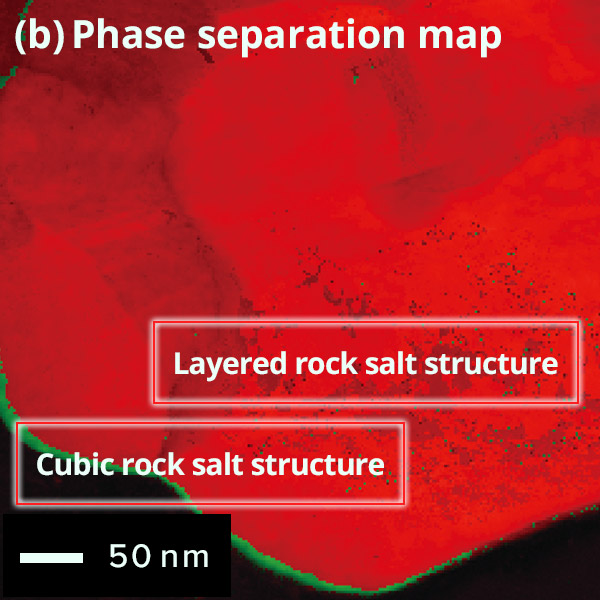

The figure below shows the results of crystal orientation and structure analysis of

particles within a cathode active material using Precession Electron Diffraction

(PED).

PED is an electron diffraction technique that reduces dynamical diffraction effects by

precessing the incident electron beam at a fixed tilt angle relative to the optical

axis.

By collecting electron diffraction patterns at each scanned point, (a) crystal

orientation maps and (b) phase distribution maps can be generated.

Map: Crystal orientation map of cathode active material

particle

Colored according to the crystal orientation of particles

Phase Map of cathode active material

particle

Difference of

surface and inside structures in color

Red: Layered rock salt structure,

Green: Cubic

rock salt structure

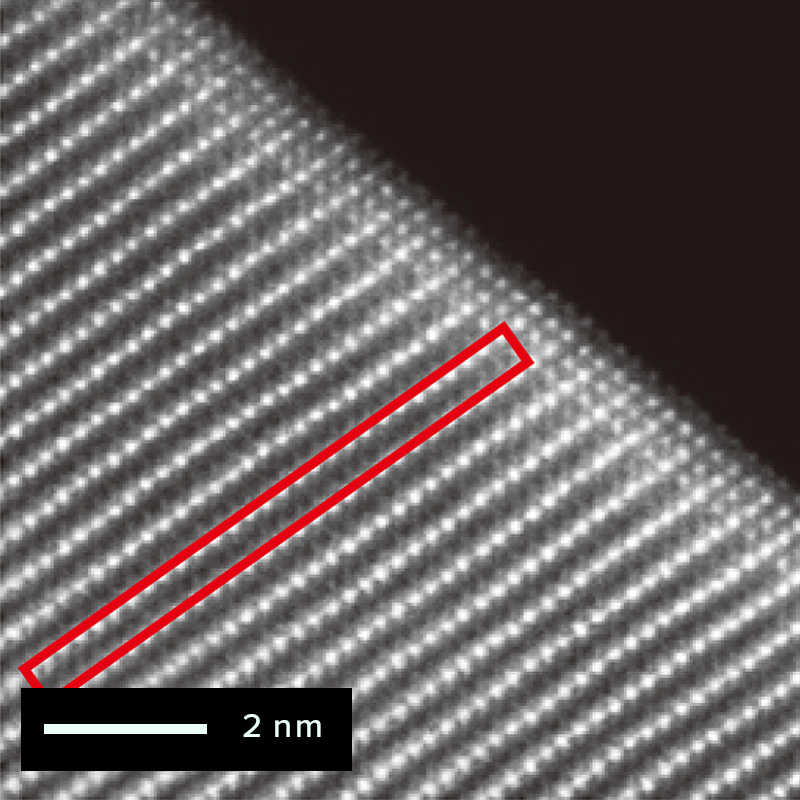

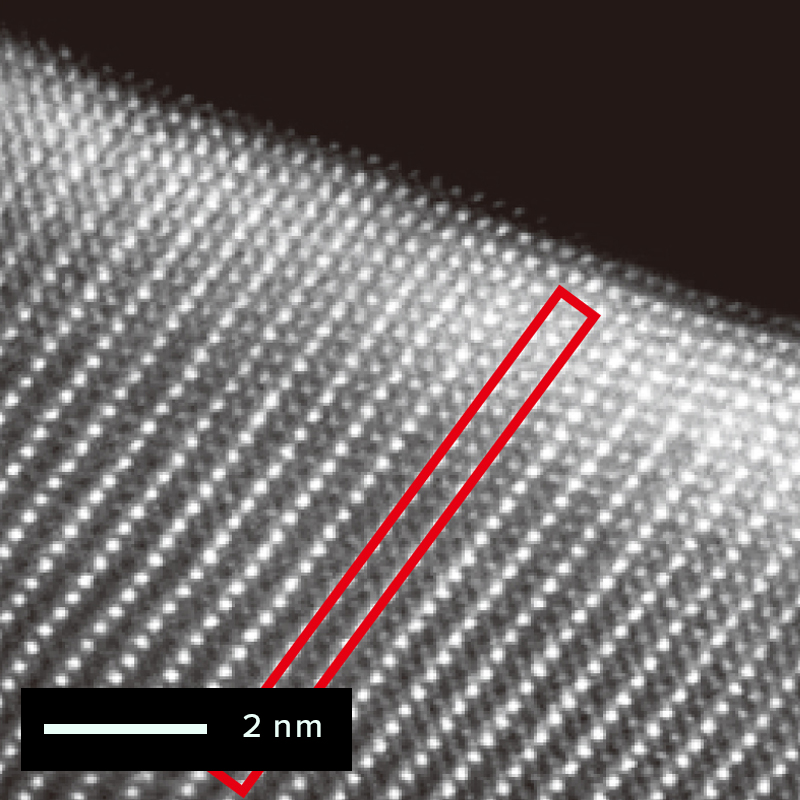

The figure below shows an example of the surface of a cathode active material particle

observed before and after charging/discharging using atomic-resolution HAADF-STEM

imaging.

The triatomic layer on the electrode surface of the active material particle changes

after charging/discharging.

However, almost no atomic bright spots are visible at the sites occupied by lithium and

oxygen within the red frame. This is expected since light elements such as lithium are

difficult to detect using the STEM-HAADF method.

On the other hand, after charging and discharging, atomic bright spots appear at the

lithium sites within the red frame.

These bright spots indicate the phenomenon of cation mixing, where transition metal ions

occupy lithium sites.

Before charging/discharging

After charging/discharging

NMC structure

refer to :

J.Appl.Cryst.(2011).44,1272-1276

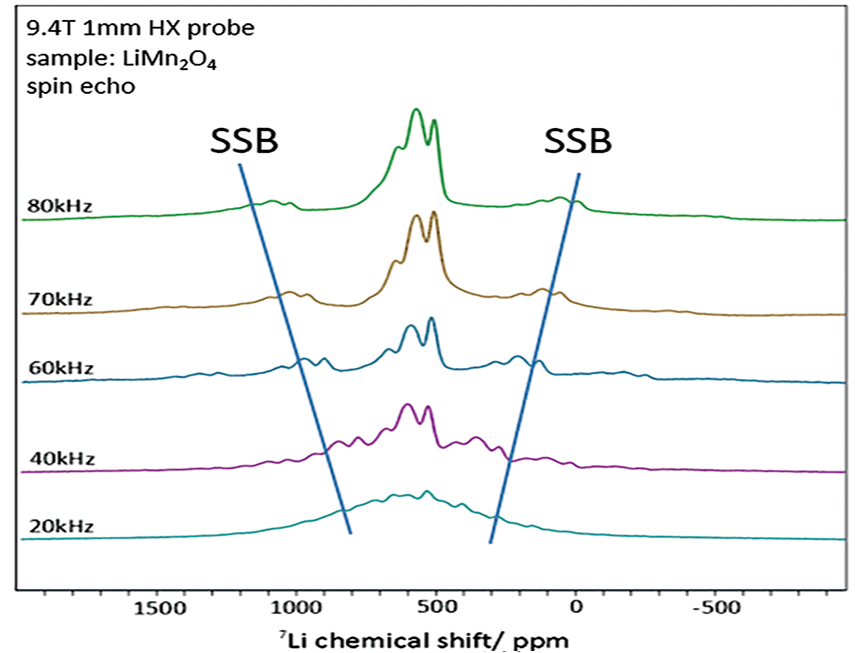

7Li solid-state NMR is an effective technique for structural analysis of

cathode active materials. Solid-state NMR can probe lithium within the crystal structure

of the entire sample and complements X-ray diffraction methods. Moreover, NMR supports

quantification of subtle structural changes observed in microscopic TEM analyses.

In the lithium spectrum of cathode active materials, a characteristic broadening over

several thousand ppm occurs due to paramagnetic interactions between transition metals

(TMs) and lithium.

Commonly used solid-state magic angle spinning (MAS) probes with diameters of 3.2 mm or

4 mm often yield spectra compromised by spinning sidebands (SSBs) caused by limited

excitation range and relatively slow sample spinning.

However, using ultra-fast MAS probes with diameters of 1 mm or less shifts the SSBs away

from the main peaks, producing clearer spectra (Fig. 1).

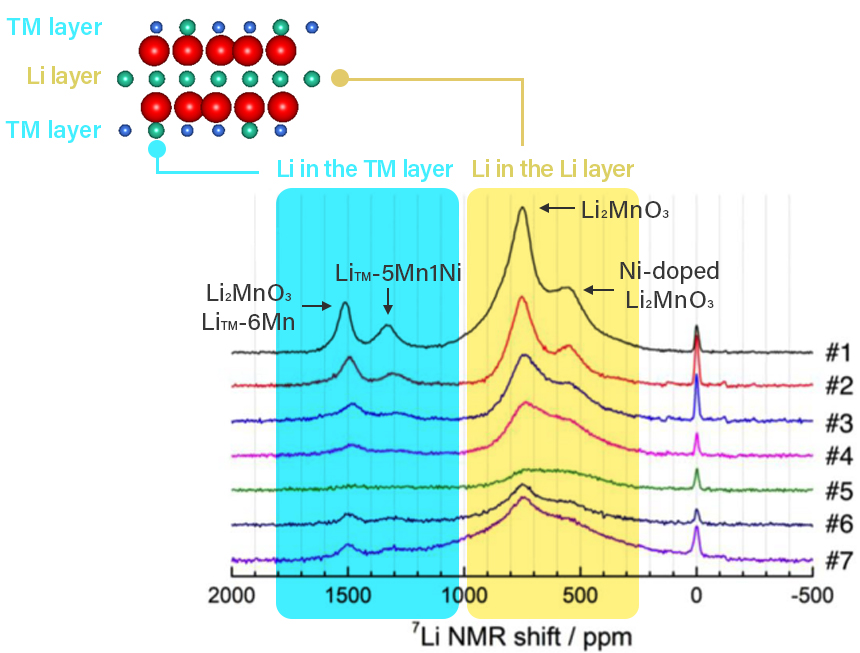

Furthermore, combining this with the recently developed MATPASS technique enables the

acquisition of 7Li spectra free from SSBs (Fig. 2).

Figure 2 shows an example of 7Li MATPASS spectra obtained during charging and

discharging of a lithium-rich layered cathode active material Li1.2Ni0.2Mn0.6O2.

Four major peaks are observed in the uncharged state (#1). Chemical shifts from 0 to

1000 ppm correspond to lithium in the lithium layers, while shifts from 1000 to 2000 ppm

correspond to lithium in the transition metal layers (LiTM).

Additionally, peak positions vary depending on whether the transition metal near lithium

is "Mn only" or partially substituted by Ni.

The lithium-related signals decrease during charging (#2 to #5) as lithium is extracted

from the structure, then recover upon discharge (#7) as lithium reintegrates.

Solid-state NMR thus allows the observation of lithium departure during charging and its

return during discharging via spectral changes, enabling analysis of lithium behavior

related to structural degradation.

Figure 1: 7Li Solid-state NMR spectra of MAS frequency dependence

Figure 2: 7Li MATPASS spectrum reflecting

lithium in

cathode active material structure during charging and discharging

refer to : Scientific Reports (2020) 10 : 10048

Anode

Anode

Material

Anode Active Material of Lithium-Ion Rechargeable Batteries

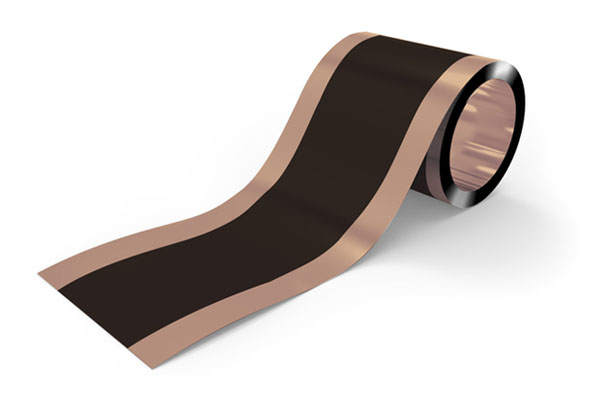

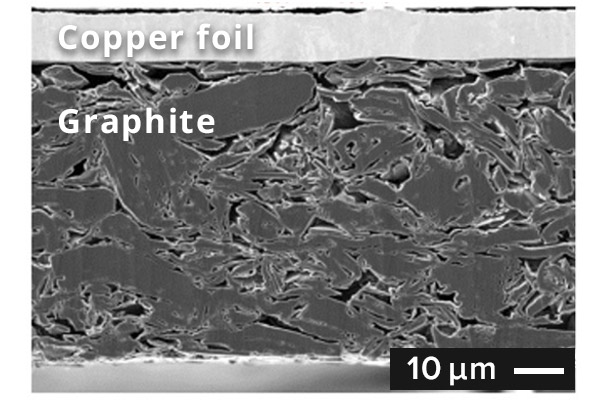

A typical anode of a lithium-ion battery consists of a current collector, anode active material, conductive additive, and binder. Copper foil is used as the current collector. Similar to the cathode, a slurry composed of the anode active material, conductive additive, and a binder dissolved in a solvent is applied onto the current collector.

Slurry which are various materials kneaded by solution

Anode current collector with slurry applied on copper foil

SEM image of graphite anode cross section

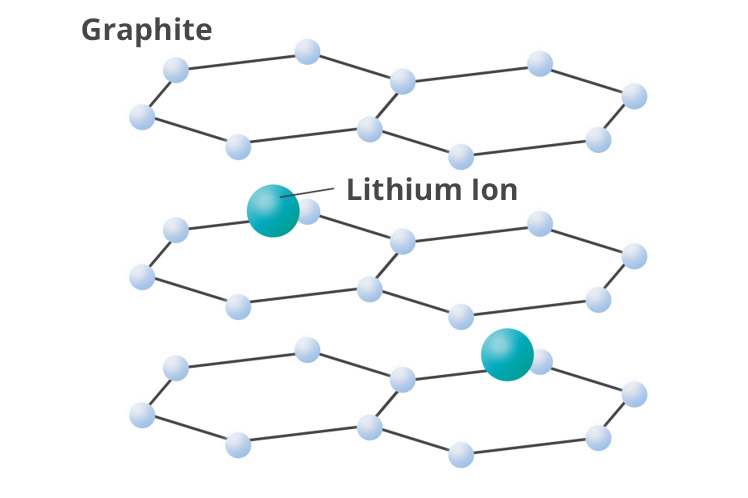

Schematic diagram of graphite with lithium ion inserted

In general, graphite is used as the active material for anodes. During charging,

lithium ions from the cathode intercalate into the layered structure of the

graphite. The theoretical capacity of graphite is 372 mAh/g. Although this is

not as high as the capacity of lithium metal (3,860 mAh/g), graphite anodes are

widely used due to their high safety and reliability.

On the other hand, silicon anodes, which offer a high theoretical capacity of

4,200 mAh/g, are being actively researched and developed. Silicon is attracting

attention as a potential alternative to carbon-based anodes because of its high

capacity and abundant availability. Despite challenges such as large volume

changes during charging and discharging, which affect cycle life, silicon is

considered a promising material for use in solid-state batteries.

Current collector foil for anode

Similar to the cathode current collector, copper foil used for the anode offers

resistance to both the electrolyte solution and oxidation, making it a

corrosion-resistant material. The operating potential of an anode with graphite as the

active material typically ranges from around 0.1 to 1.5 V vs. Li+/Li.

Although aluminum foil is lighter and less expensive, it forms a Li-Al alloy at

approximately 0.6 V vs. Li+/Li when used in anodes, which results in the

degradation of battery capacity. Therefore, copper foil--offering good resistance to the

electrolyte and oxidation, along with relatively low cost--is used for anode current

collectors.

Electrolyte Solution

Electrolyte

Solution

Electrolyte solution in lithium ion battery

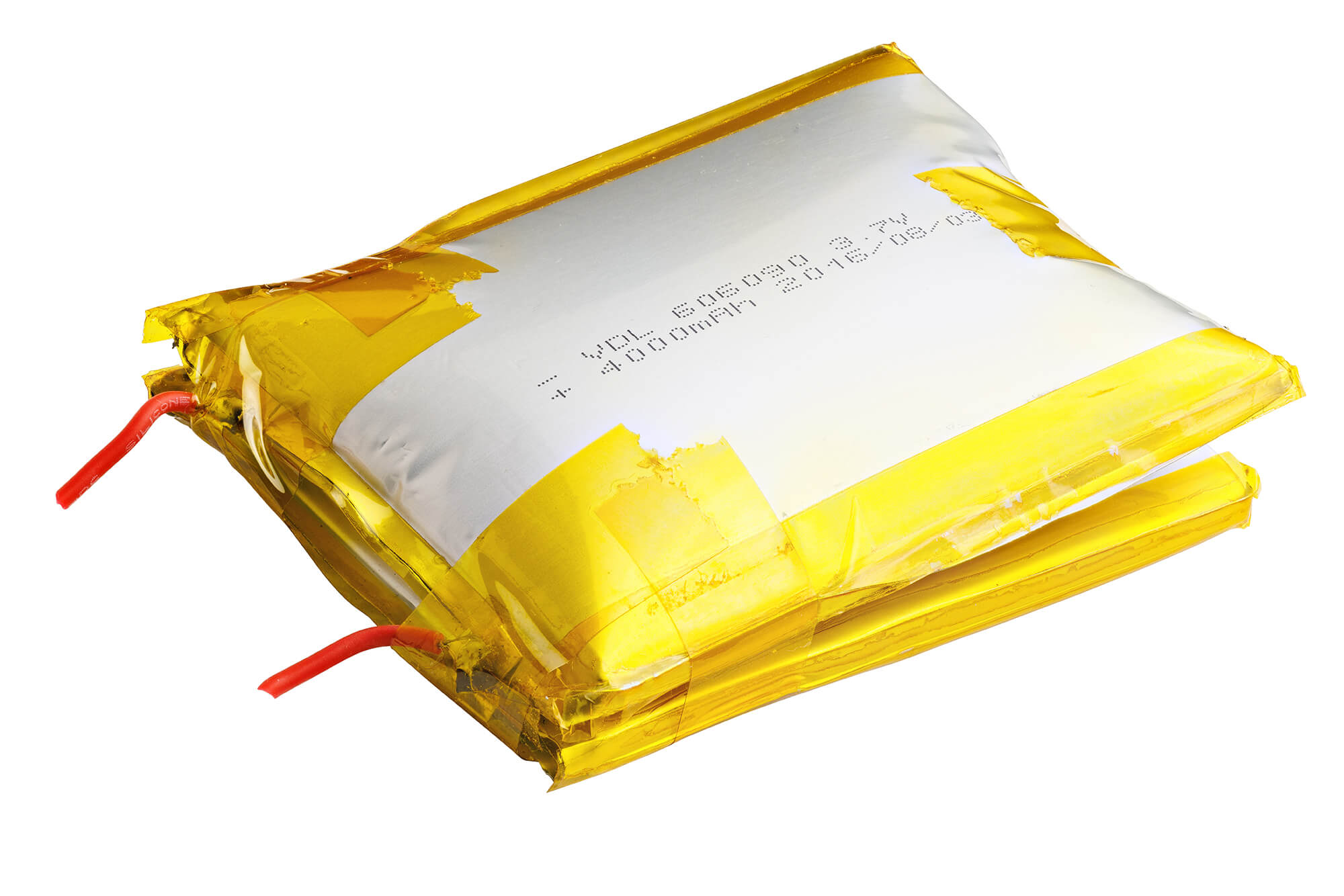

LIB expanded by the gas evolved by the decomposition of the electrolyte solution

The electrolyte solution in a lithium-ion battery plays a crucial role in

transporting lithium ions. It is an ion-conductive solution composed of an ionic

compound dissolved in a polar solvent, such as water.

In typical lithium-ion batteries, the electrolyte consists of a mixture of

organic solvents--such as ethylene carbonate (EC), dimethyl carbonate (DMC), and

diethyl carbonate (DEC)--which allow the battery to operate at high potentials

without undergoing oxidative decomposition.

However, organic solvents tend to decompose due to repeated charge/discharge

cycles, over-discharge, or overcharge, which leads to deterioration of the

electrolyte's performance.

While organic solvent-based electrolytes offer higher voltage tolerance than

aqueous electrolytes, they are flammable and are classified as hazardous

materials (flammable liquids) under fire safety regulations. In particular, if

an internal short circuit occurs due to overcharging, over-discharging, or

external shock, a large current can flow instantaneously, generating heat and

potentially igniting the flammable electrolyte.

Under overcharge conditions, cathode materials degrade, and the released oxygen

oxidizes and decomposes the electrolyte, producing gas. In over-discharge

conditions, the copper foil used in the anode may dissolve, resulting in copper

elution and the reductive decomposition of the electrolyte, which also generates

significant gas.

The electrolyte is a key material for both battery life and safety. Therefore,

research and development are underway to create electrolytes that are

non-flammable and stable at high voltages. In particular, the evaluation of

chemical stability, voltage tolerance with respect to the electrodes, and

decomposition behavior during charge/discharge cycles is becoming increasingly

important. The degradation of the electrolyte is often assessed through the

analysis of the evolved gases.

Analysis Example of

Electrolyte Solution

Degradation Analysis of Electrolyte Solution Using

AI-Assisted Structural Analysis (MS: Mass Spectrometry)

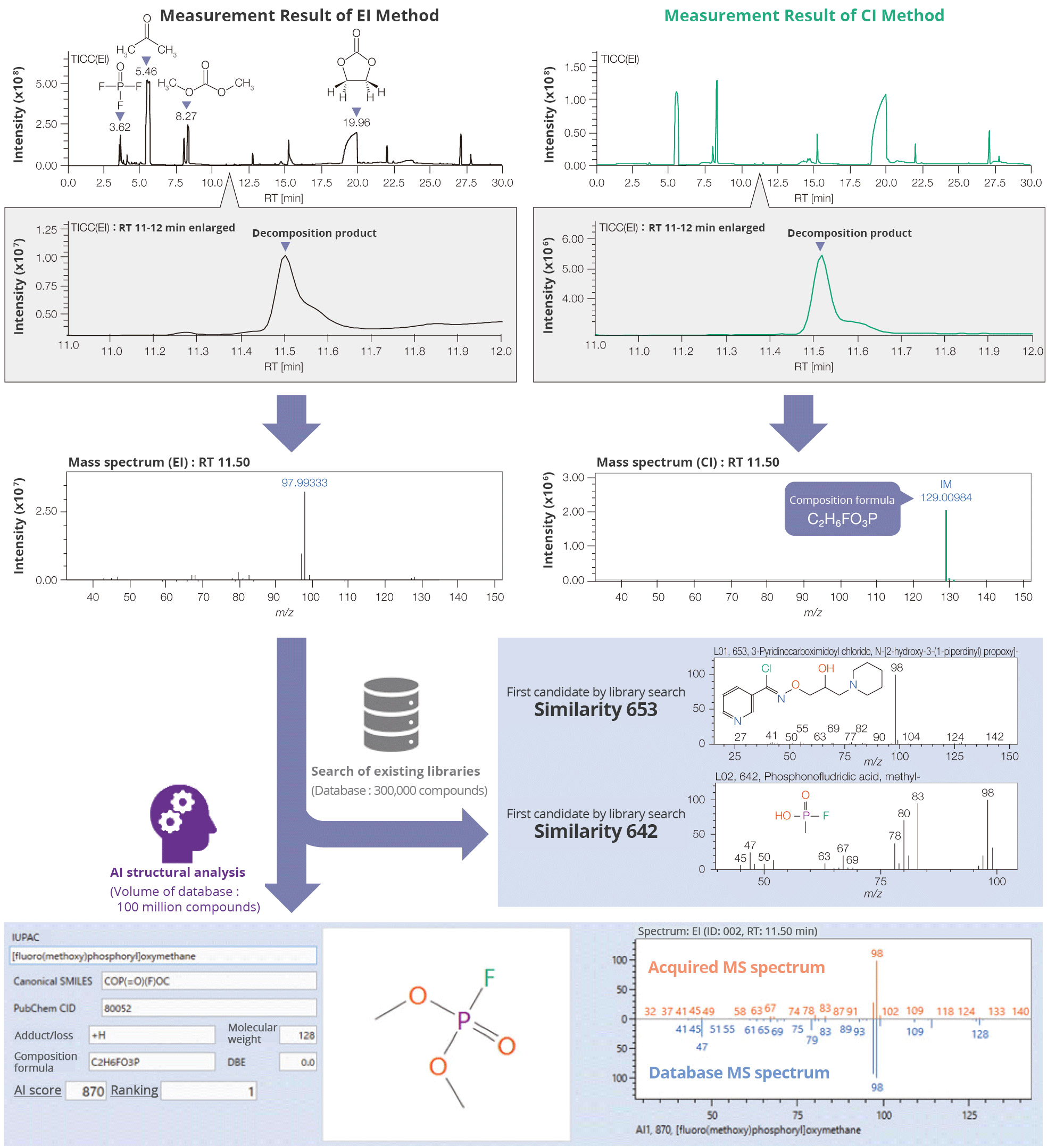

Case Study: Electrolyte Solution Degradation Analysis in LIBs

This case study analyzes the degradation of electrolyte solutions in lithium-ion

batteries (LIBs) after undergoing charge and discharge cycles. The electrolyte solution

was extracted from a disassembled battery using acetone and analyzed using a

high-performance gas chromatograph time-of-flight mass spectrometer (GC-TOF-MS).

Measurements were conducted using both the hard ionization method (EI: Electron

Ionization) and the soft ionization method (CI: Chemical Ionization). The primary

detected components included the extraction solvent (acetone), electrolyte solvents, and

the electrolyte itself. In addition, trace amounts of decomposition products from the

electrolyte and electrolyte solution were identified.

As an example, a decomposition product with a retention time of 11.5 minutes on the

Total Ion Current Chromatogram (TICC) was analyzed. Compound identification typically

requires a library search using mass spectral databases. While conventional databases

contain around 300,000 compounds, msFineAnalysis AI--our AI-based unknown

substance structure analysis software--can search a database containing approximately 100

million compounds.

Moreover, molecular weight and compositional formula information obtained from the CI

method can be used to refine search results, enabling more precise compound

identification. In this analysis, using AI-based structure analysis, the compound

C2H6FO3P (fluoro(methoxy)phosphoryl oxymethane)

was identified from over 800 candidate structures in the mass spectrum.

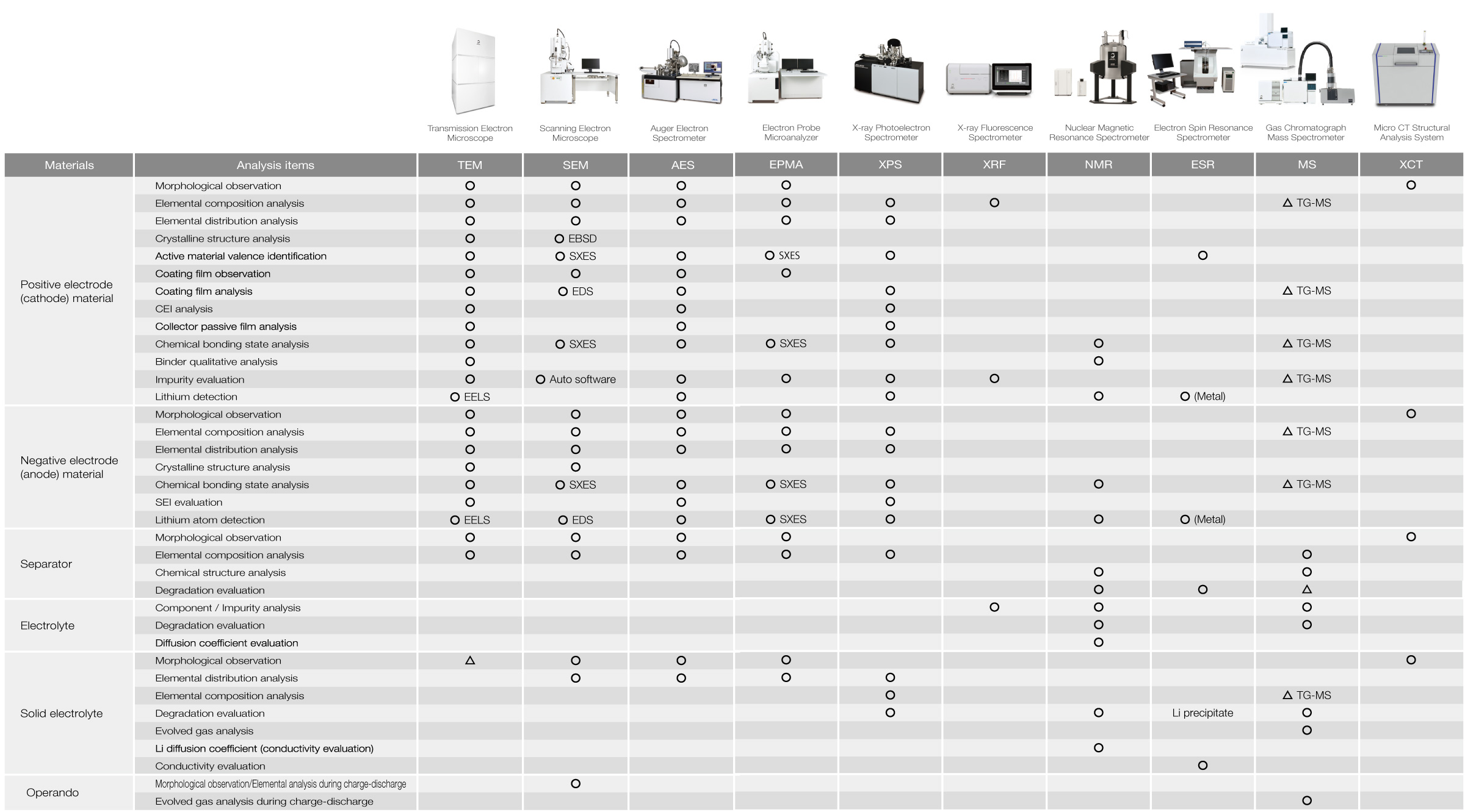

Analysis Items for Lithium-Ion Batteries (LIBs) and Corresponding JEOL Instruments

The table below lists JEOL's instruments categorized by their analytical and evaluation purposes. For more details on their applications, please refer to the catalogs and technical documents for each instrument or contact JEOL.

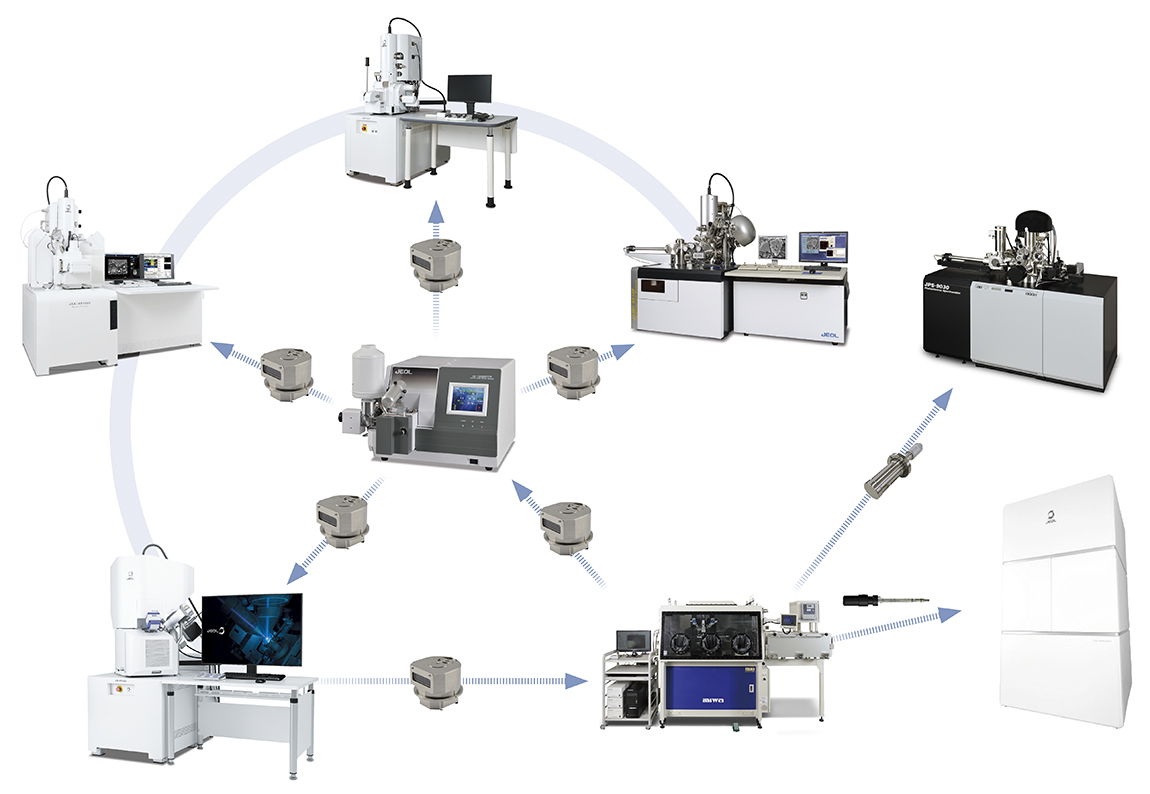

Importance of air-isolation transfer in battery analysis

Materials used in batteries contain highly reactive lithium, which poses a risk

of alteration upon exposure to air. Therefore, manufacturing requires an

air-isolated environment, such as a dry room, and material analysis--including

specimen preparation, observation, and analysis--must also be conducted in an

air-isolated environment. Air-isolated instruments and systems that integrate

multiple analytical devices are effective for lithium-ion battery analysis.

JEOL's instrument lineup provides systems that enable processing, observation,

and analysis within an air-isolated environment.

Click the button below to return to Battery TOP

Contacts

JEOL provides a variety of support services to ensure that our customers can use our products with peace of mind.

Please feel free to contact us.