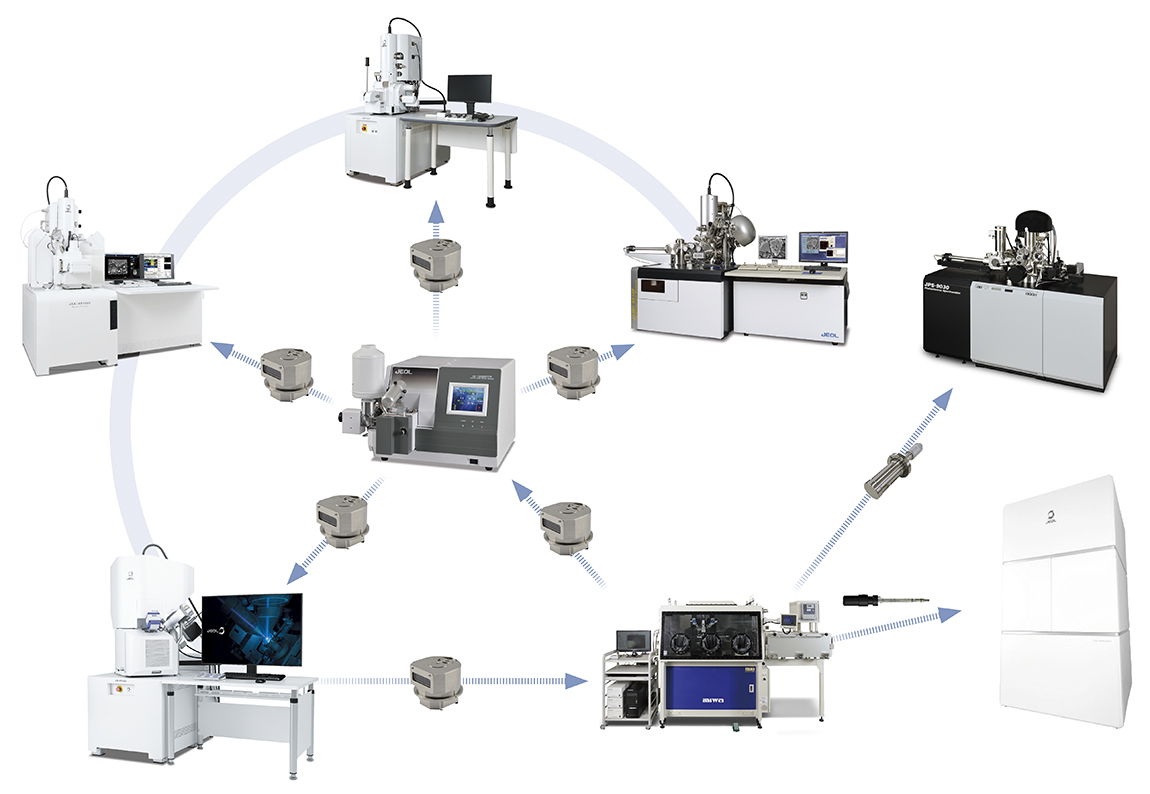

Air-Isolation Transfer

Air-Isolation Transfer System

Materials used in batteries contain highly reactive lithium. There is a risk of alteration when exposed to air. Therefore, an air-isolated environment such as a dry room is required during manufacturing, and specimen preparation, observation, and analysis must be performed in an air-isolated environment. Air-isolated instruments and integrated systems that connect different analytical devices are effective for lithium-ion battery analysis.

JEOL's instrument lineup offers systems that enable processing, observation, and analysis within an air-isolated environment.

A movie introducing Air Isolation System is available.

Click the

play button in the box above, and the movie starts. (4 min 12 sec).

Air-Isolated Processing and Observation Tool

The use of a transfer vessel enables air-isolated transfer between analysis instruments for seamless

integration.

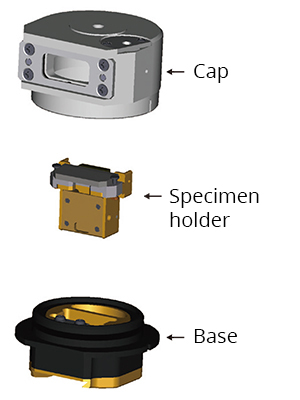

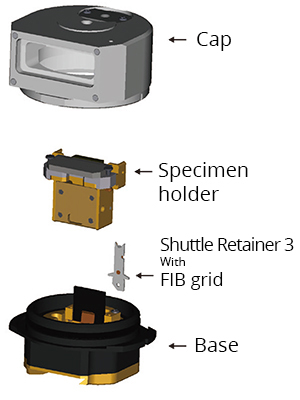

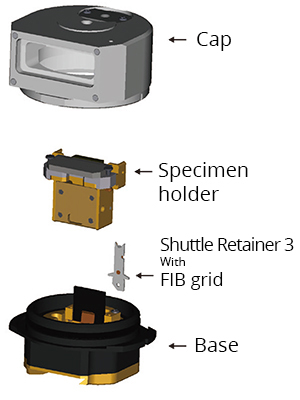

These transfer vessels consist of various specimen holders sealed with base parts and caps, as shown in the

figure below.

For TEM and XPS, where transfer vessels cannot be used, dedicated air-isolation holders for analysis are

available to maintain an air-isolated environment.

CP-SEM compatible

CP-EPMA(Electron Probe Micro Analyzer) compatible transfer vessel

CP-FIB compatible transfer vessel

(CP-FIB-SEM-TEM linkage)

CP-AES compatible transfer vessel

TEM air-isolation observation/analysis holder

XPS air-isolation observation/analysis holder

Processing and observation tools for microareas selected from wide cross-sectional regions

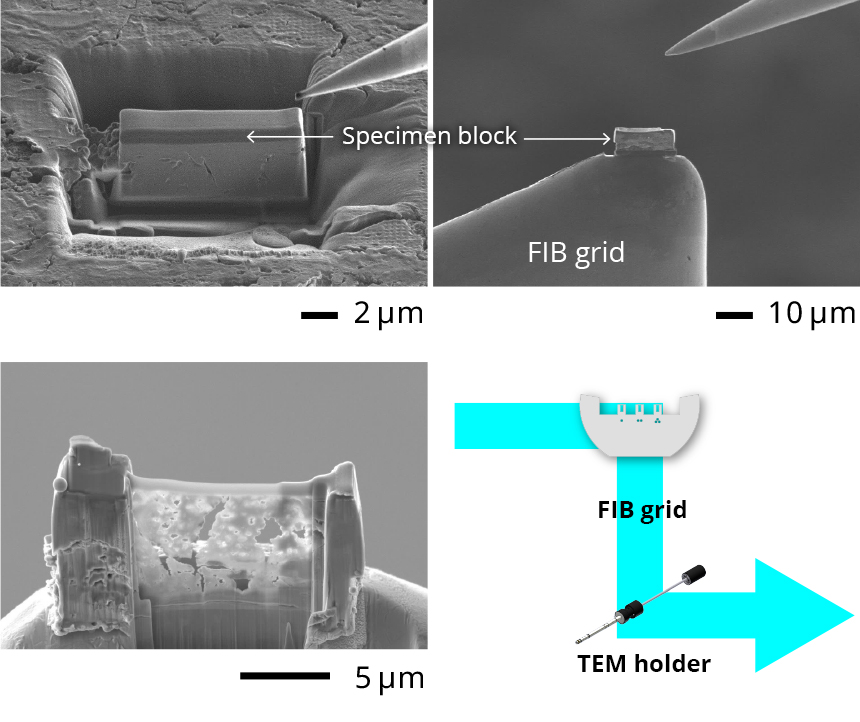

The holder shown in the figure below can accommodate a TEM holder tip, enabling

both wide-area cross-sectioning using CP and thin-film milling using FIB-SEM within the same holder.

Another advantage of this holder is that the FIB grid does not need to be handled directly with tweezers

after thin sectioning; instead, the TEM tip with the mounted FIB grid is placed in the holder. This system

significantly reduces the risk of damage when handling small TEM specimens. Its air-isolation design also

makes it ideal for handling TEM samples in a glove box, especially for air-sensitive materials such as

battery components.

The procedure is as follows: During cross-sectioning, the battery is clipped into the clip-type holder and

the CP is used to prepare the cross-section. Once the cross-section is complete, the holder is capped and

transferred to the FIB-SEM in an air-isolated environment for observation and analysis. When the desired

TEM observation area is identified, a block is processed by FIB and transferred to the TEM holder tip

using a probe. Lamella thinning is then performed by FIB to achieve a thickness suitable for TEM

observation. The block is capped again and transferred to the glove box without air exposure, where the

TEM tip is installed on the air-isolated TEM holder and removed from the glove box.

This tool is designed to enable TEM observation of selected areas from a wide cross-sectional region

efficiently and safely.

CP-FIB compatible transfer vessel

CP-FIB-SEM-TEM linkage

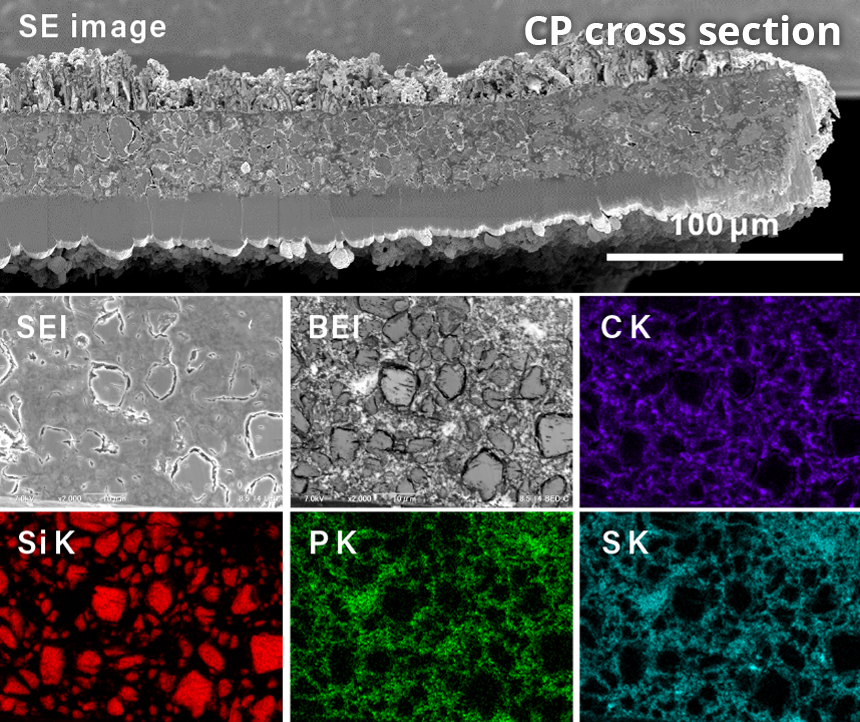

CP cross section and thin film extraction position determination

SEM image(secondary electron) and EDS map

FIB thin film milling

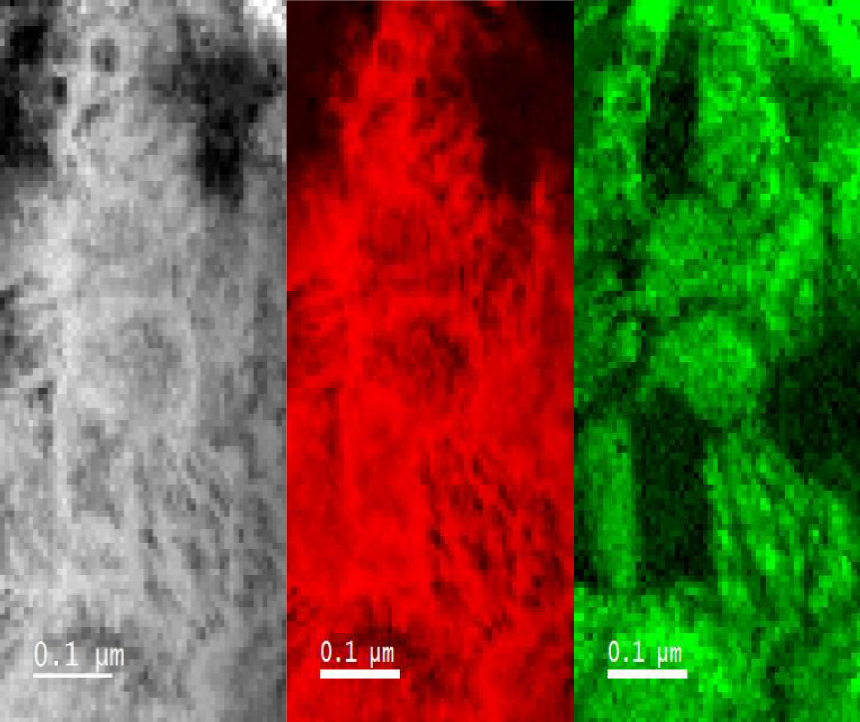

TEM observation/analysis

ADF-STEM image and EELS map

Sample courtesy:

Prof. Atsunori Matsuda

Department of Electrical and

Electronic Information Engineering

Toyohashi University of Technology

A movie introducing Specimen preparation of internal target -

battery multi-layers is available.

Click the play button in the box above, and the movie starts. (1 min

21 sec).

Click the button below to return to Battery TOP

Contacts

JEOL provides a variety of support services to ensure that our customers can use our products with peace of mind.

Please feel free to contact us.