Qualitative Analysis of Catalytic Reaction Products using msFineAnalysis AI - Upcycling of Discarded Polystyrene -

MSTips No. 456

General

Recently, attention is increasingly focused on upcycling of discarded plastic products to create a chemical product of higher quality or value than the original. To elevate chemical upcycling using catalytic reaction to an economically viable level, accurate analysis of reaction products is essential. While gas chromatography - mass spectrometry (GC-MS) is commonly used to determine reaction products, typical database search based on GC-MS often fails to fully identify these products.

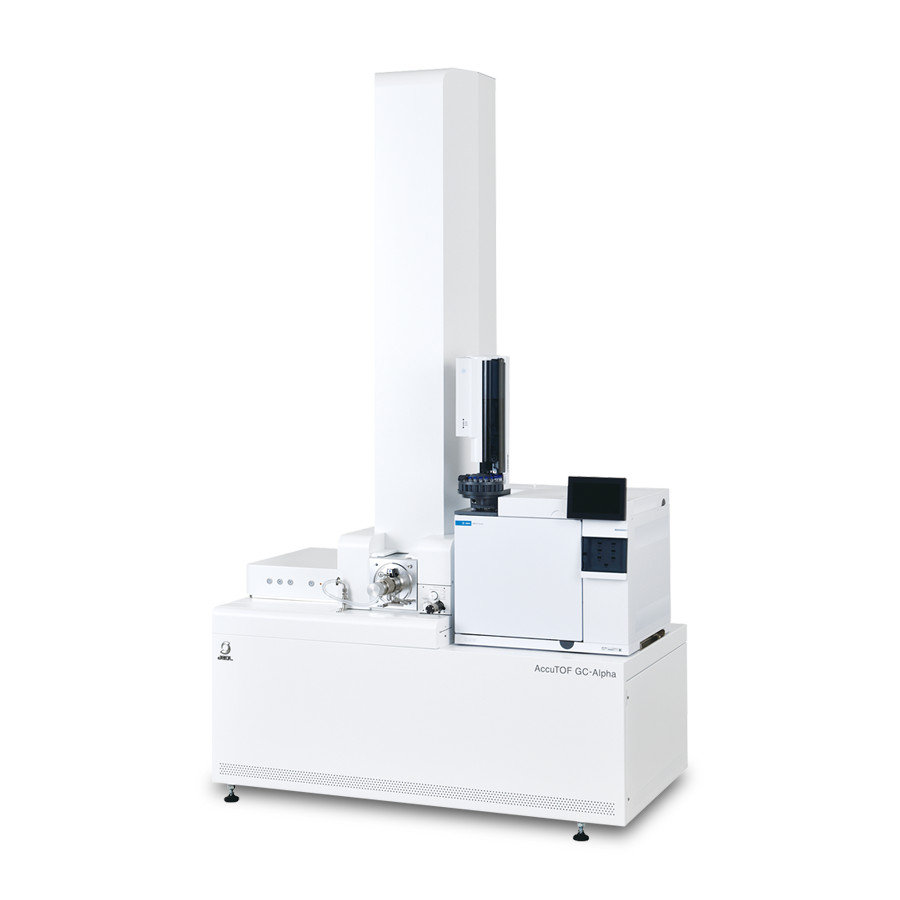

JEOL’s GC-high resolution mass spectrometer (GC-HRMS), JMS-T2000GC, is capable of: 1) high precision mass analysis; 2) detection of molecular and fragment ions through electron ionization (EI) and soft ionization (SI); and 3) auto analysis of acquired data by msFineAnalysis AI to determine chemical formulas and predict chemical structures. These features make it possible to determine chemical structures of such components that conventional GC-MS is unable to.

In this work, we reacted discarded polystyrene using a catalyst, which is a known upcycling technique[1], and qualitatively analyzed the resulting products in a JMS-T2000GC and msFineAnalysis AI.

Experiment

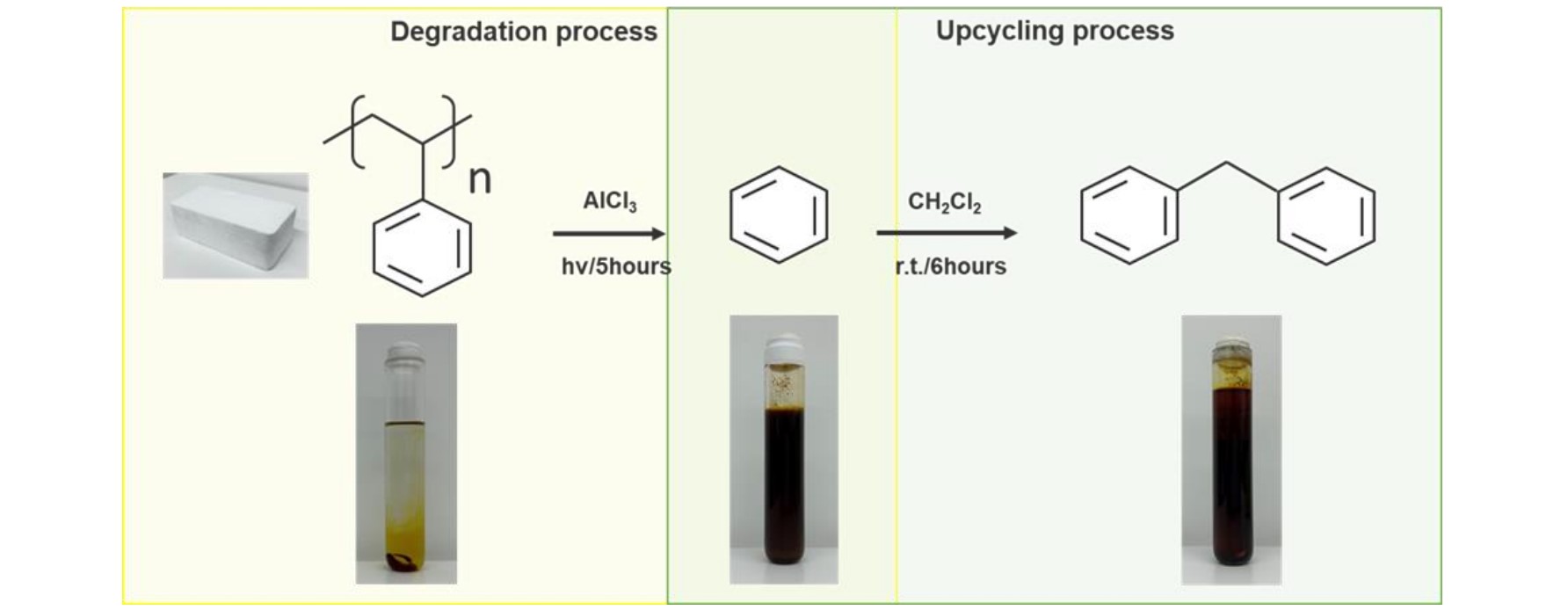

A discarded polystyrene sample was subjected to two stages of catalytic reaction shown in Figure 1.

[Degradation Process]

1.0 g of discarded polystyrene was dissolved with 15mL of benzene (≥99.7%). The polystyrene/benzene solution was transferred to a quartz tube, and the dissolved oxygen was replaced with argon gas. 1g of anhydrous aluminum chloride (≥98%) was added as a catalyst, and the mixture was irradiated by a UV lamp (253.7 nm, 8W) for 5 hours. 1mL of the supernatant of the reacted solution was measured in the GC-HRMS.

[Upcycling Process]

5mL of dichloromethane was added to the degradation solution and let stand for 6 hours. 1mL of the supernatant of the reacted solution was measured in the GC-HRMS.

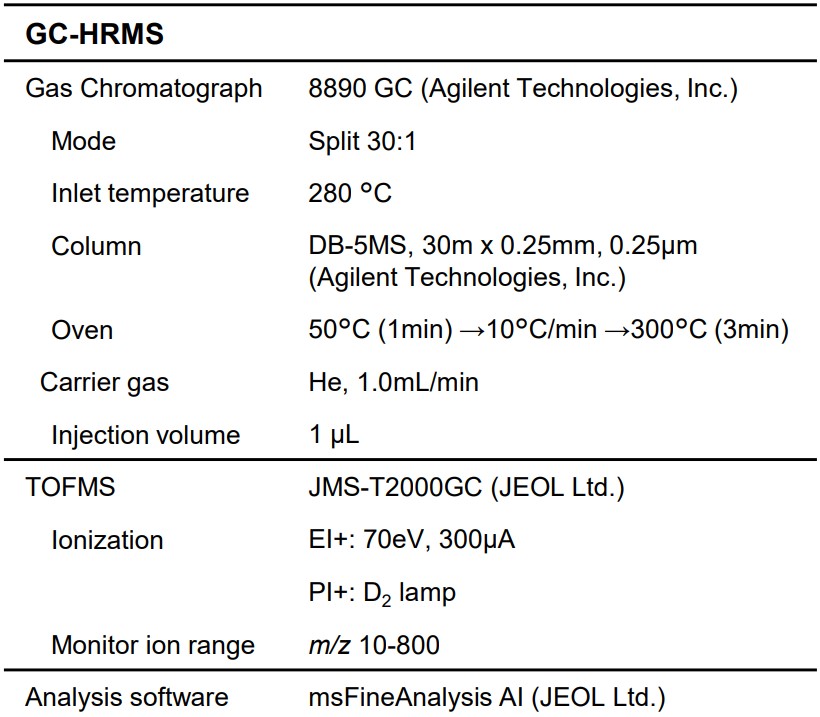

Both reaction processes took place at room temperature. EI and PI (Photo Ionization) as SI were used as ionization methods. msFineAnalysis AI was subsequently used for analysis of the acquired data. Table 1 shows the measurement conditions.

Table 1. Measurement conditions

Results and Discussion

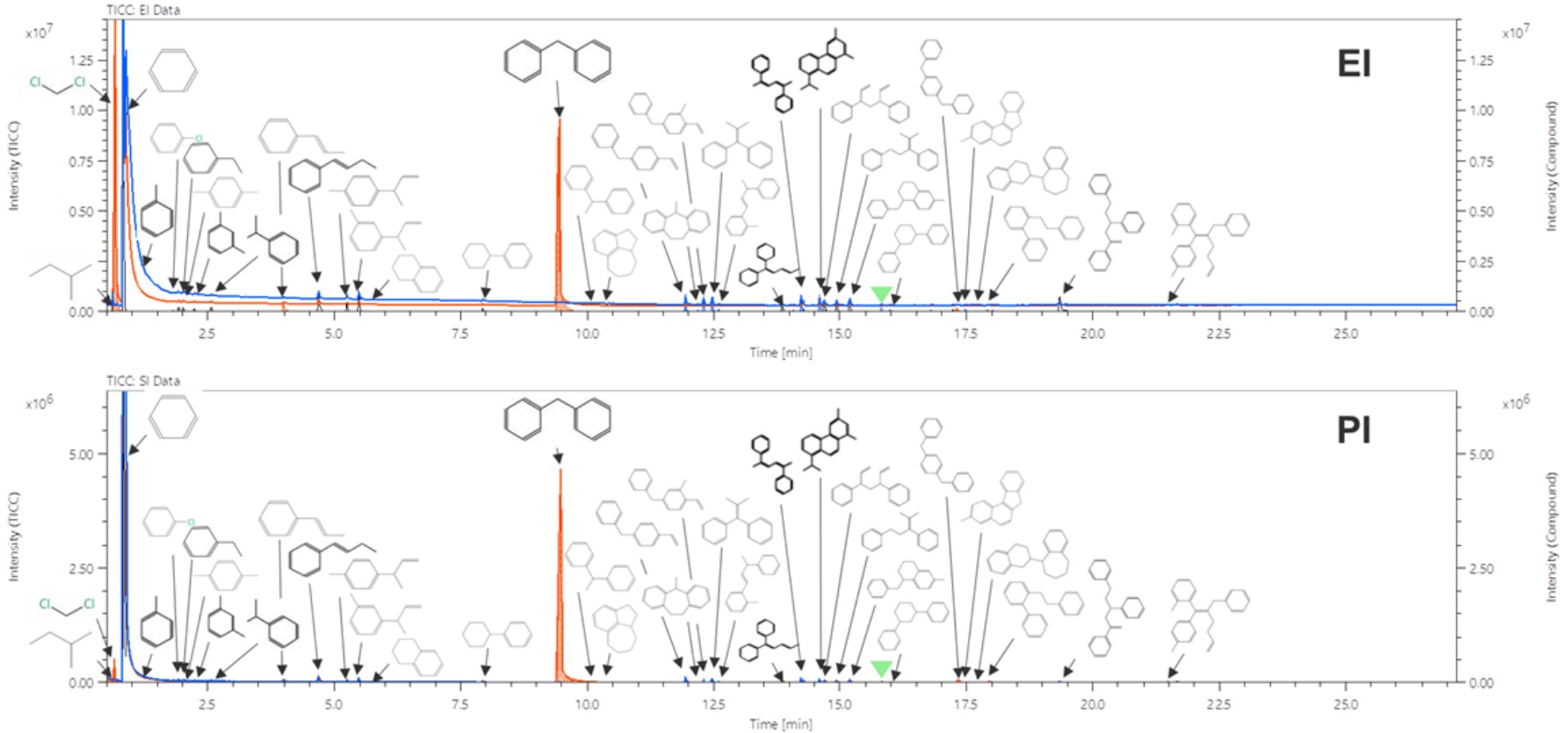

Figure 2 shows the total ion current chromatograms (TICCs) of EI and PI acquired from the solutions in degradation (blue) and upcyling (red) processes. A total of 45 components were detected, including benzene and diphenylmethane, major products in each process. For 26 components, their formulas predicted from the molecular ions did not agree with the results of NIST compound search. However, msFineAnalysis AI contains an AI database of EI mass spectra estimated from the compound structures (AI library) in addition to the NIST database. The 26 components, when examined against the AI library, matched well with the compounds having the compositional formulas predicted by molecular ions. Figure 2 shows the estimated compounds.

Figure 1. Synthetic scheme of both degradation process and upcycling process, and sample photographs

Figure 2. EI and PI TICCs of both solutions of degradation and upcycling processes

Degradation process: Blue, Upcycling process: Red

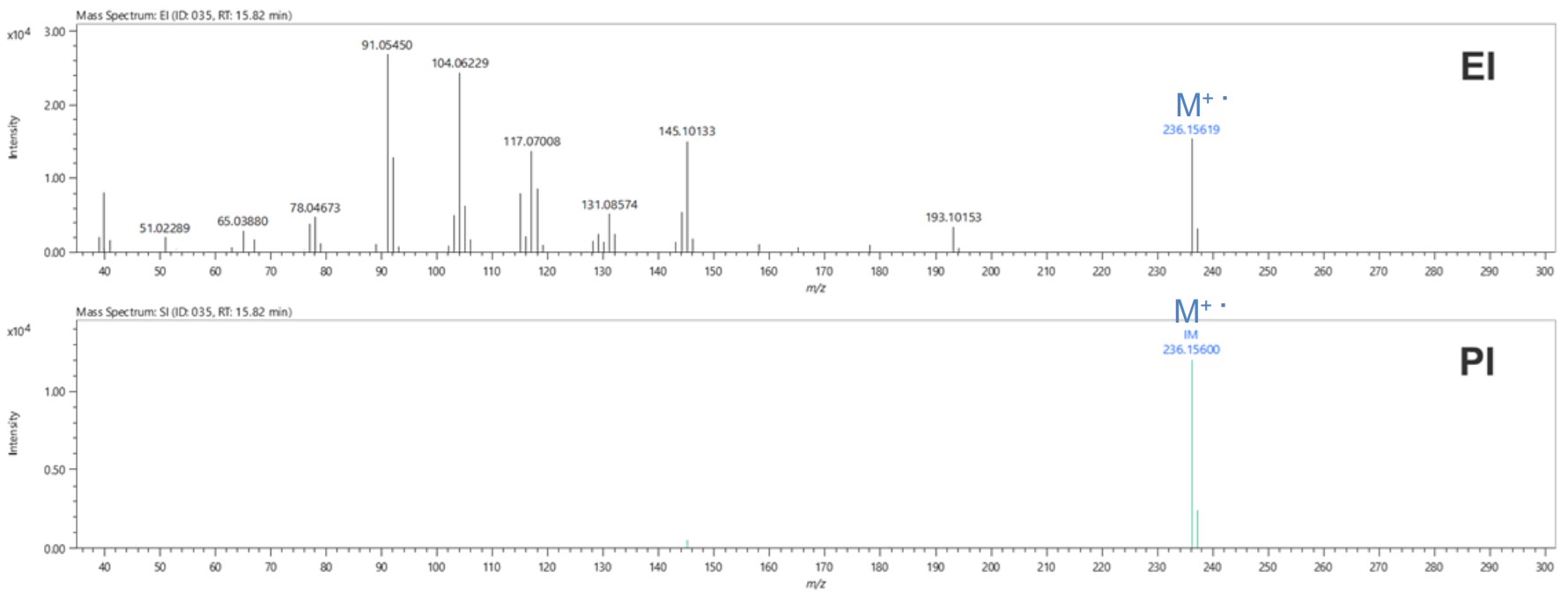

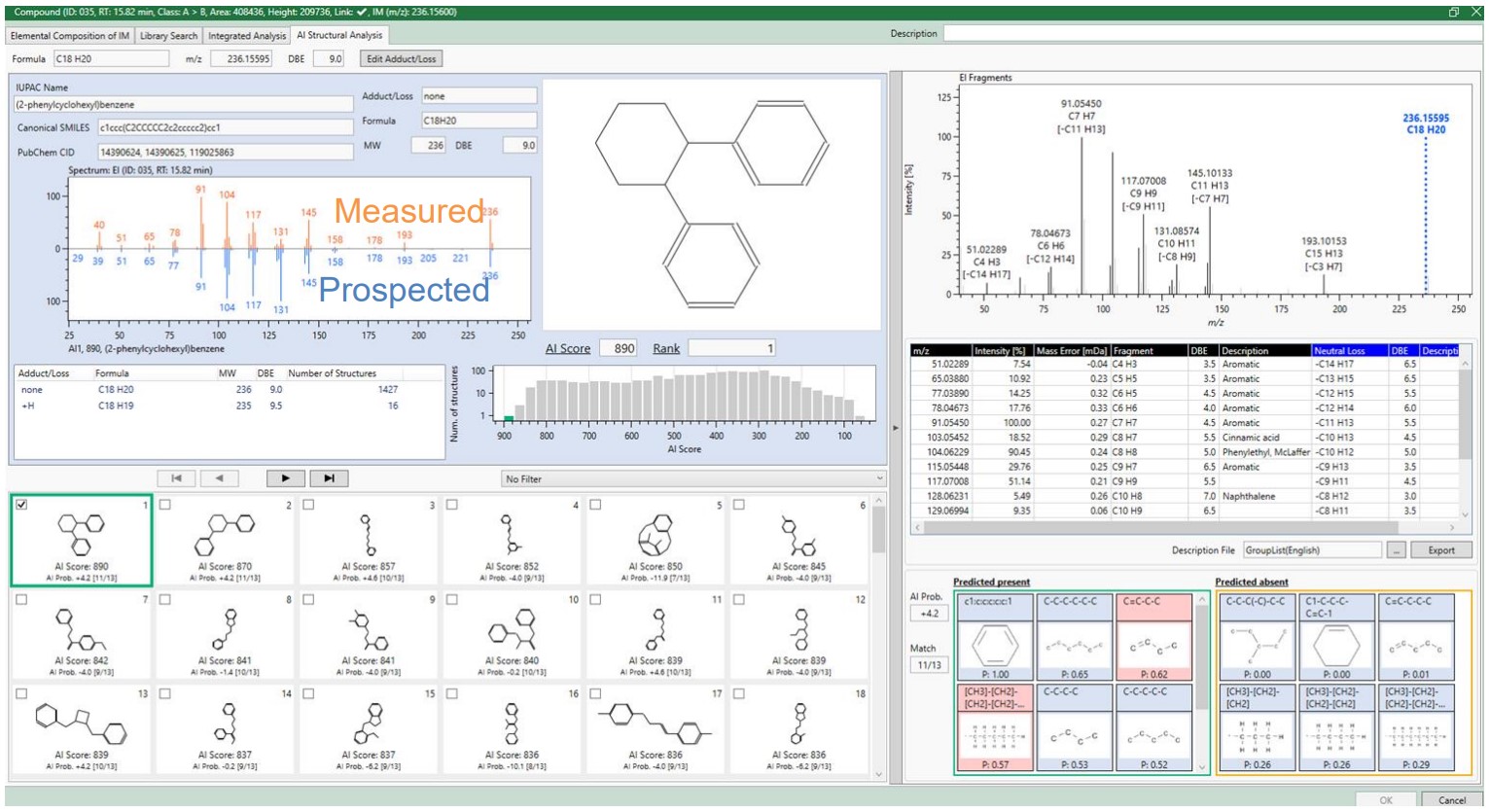

Figures 3 and 4 respectively show the mass spectra and predicted formula of the component marked by ▼ in Figure 2, which was detected at a retention time of 15.81 minutes in the degradation solution.

Its chemical composition was estimated to be C18H20 from the exact mass verified in the PI mass spectrum in Figure 3. NIST database search for the EI mass spectrum did not result in any compounds showing a similarity of 700 or more. However, the AI structural analysis in Figure 4 resulted in (2-phenylcyclohexyl)benzene, which had a chemical formula of C18H20 and also showed good agreement with the EI fragment patterns.

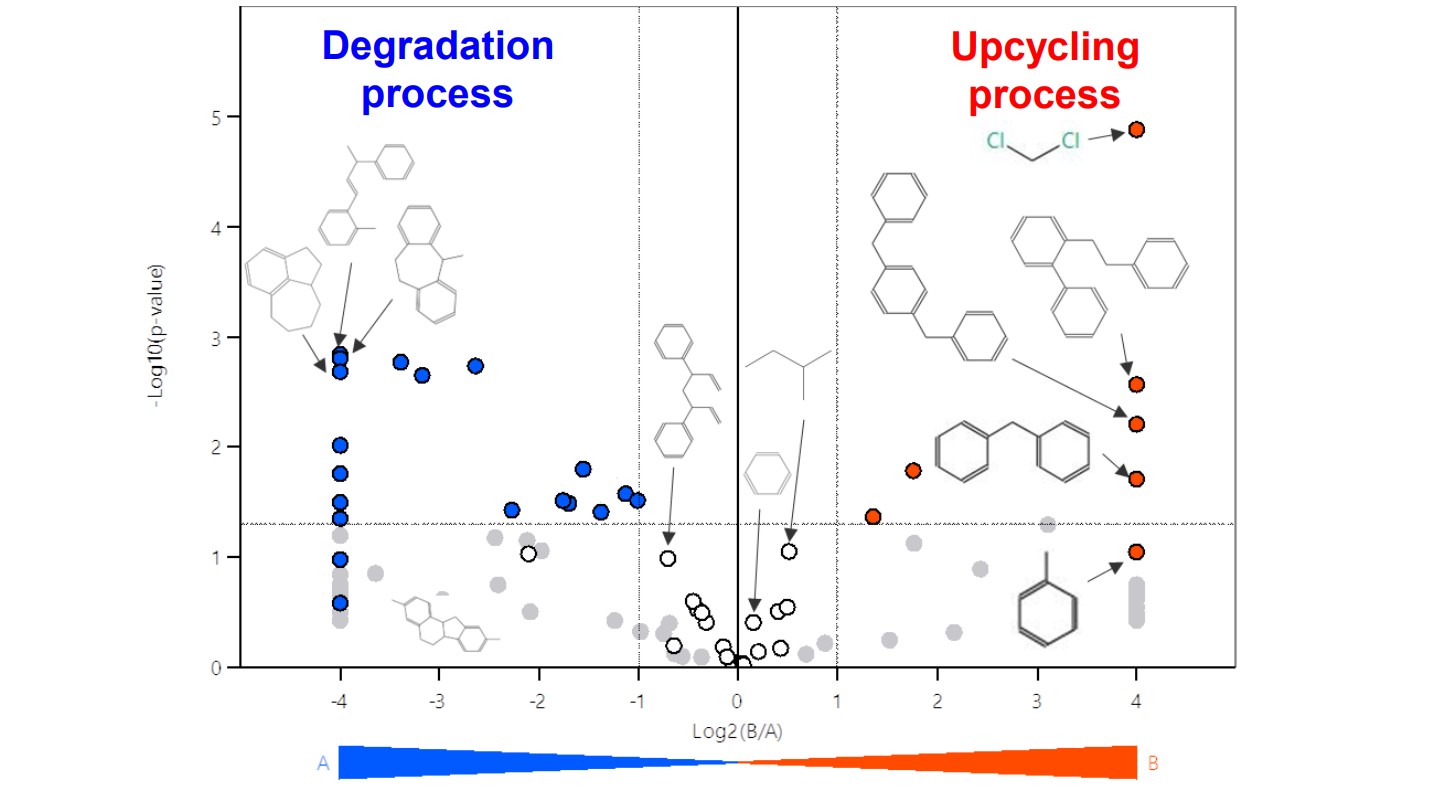

Aside from benzene, components contained in both processed solutions included 2-methylbutane and 5-phenylhepta-1,6-dien-3-ylbenzene, according to the volcano plot results in Figure 5. Components detected in the degradation solution alone were identified as a group of compounds having one or more benzene chains and polyaromatic hydrocarbons (PAHs). Also, aside from diphenylmethane, components detected in the upcycling solution alone included, 1,4-dibenzylbenzene, toluene, and dichloromethane added for reaction.

It is likely that the compounds having one or more benzene chains and PAHs detected in the degradation solution resulted from primary interaction producing benzene as well as sub-reaction producing PAHs through the catalytic reaction between the polystyrene/benzene solution and aluminum trichloride.

Figure 3. EI and PI mass spectra of the component at a retention time of 15.81 minutes

Figure 4. AI structural analysis results of the component at a retention time of 15.81 minutes in the degradation process solution

Figure 5. Volcano Plot results

Degradation process: Blue, Upcycling process: Red

Summary

The results of this work demonstrate that msFineAnalysis AI is a powerful tool for qualitative analysis, capable of predicting chemical formulas and chemical structures while saving time and labor. Accurate qualitative analysis of catalytic reaction products is useful for evaluation and scaling up of catalytic reactions.

Furthermore, volcano plotting identified differences in the components produced in the solution from each process, providing information on sub-reaction products as well.

The JMS-T2000GC and msFineAnalysis AI, proven to be effective in identifying reaction products as shown in this work, are also expected to be useful for qualitative analysis of unknown compounds.

References

[1] Zhen Xu, Fuping Pan, Mengqi Sun, Jianjun Xu, Nuwayo Eric Munyaneza, Zacary L. Croft, Gangshu (George) Cai, and Guoliang Liu,. PNAS, 2022, Vol. 119, No. 34, 1-8. https://doi.org/10.1073/pnas.2203346119

Solutions by field

Related products

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.