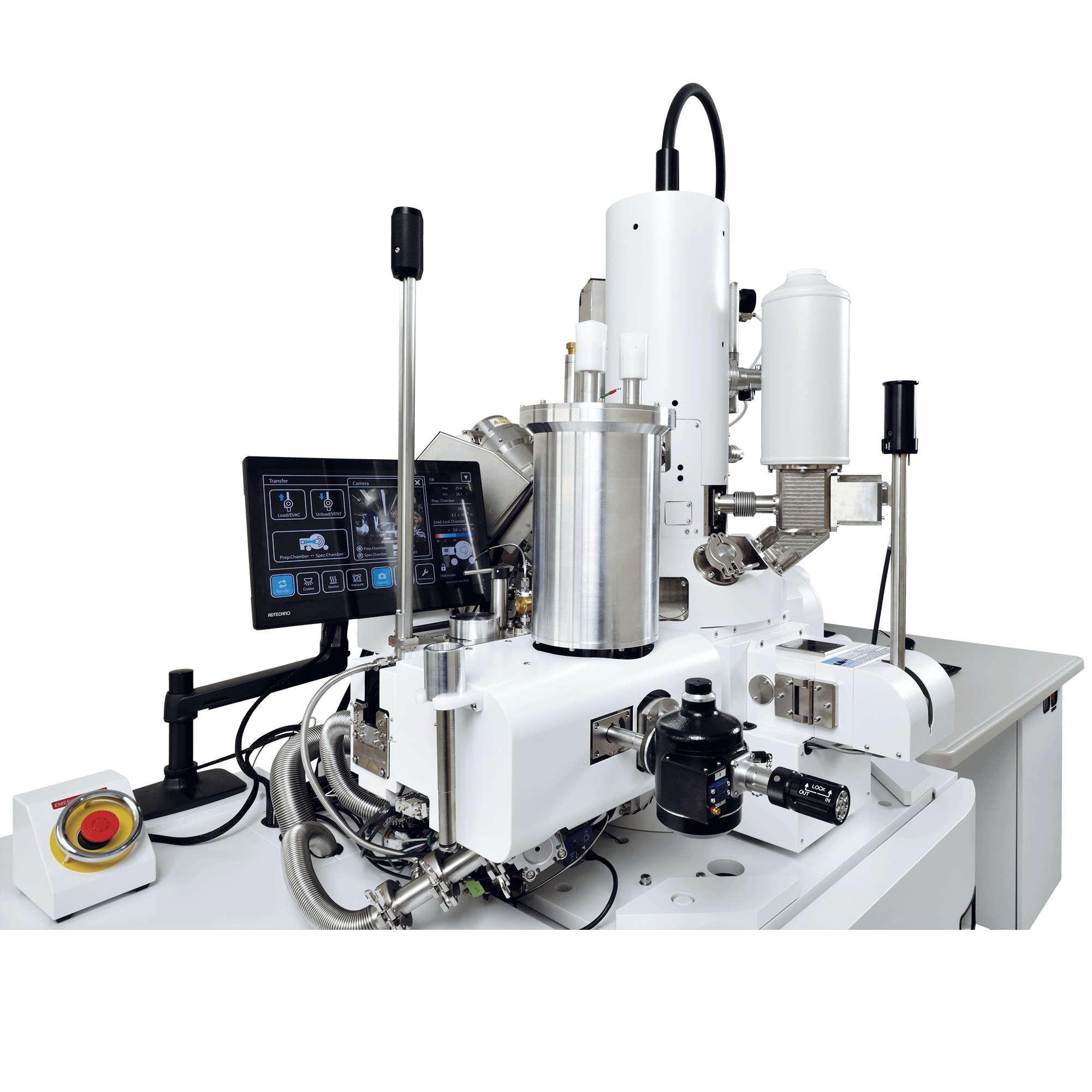

This CRYO-FIB-SEM system incorporates a liquid nitrogen cooling stage and a cryocooled specimen transfer mechanism for frozen specimens, making it possible to prepare TEM specimens such as biopolymers.

The specimen transfer mechanism has a built-in sputter coating function. Therefore, this CRYO-FIB-SEM system alone can perform a series of processes to create TEM specimens from frozen specimens including conductivity coating, protective film forming, and FIB processing.

In addition, by using JEOL's CRYO ARM™ cartridge, direct specimen transfer to the CRYO ARM™ after TEM specimen preparation becomes easier.

Features

Product video

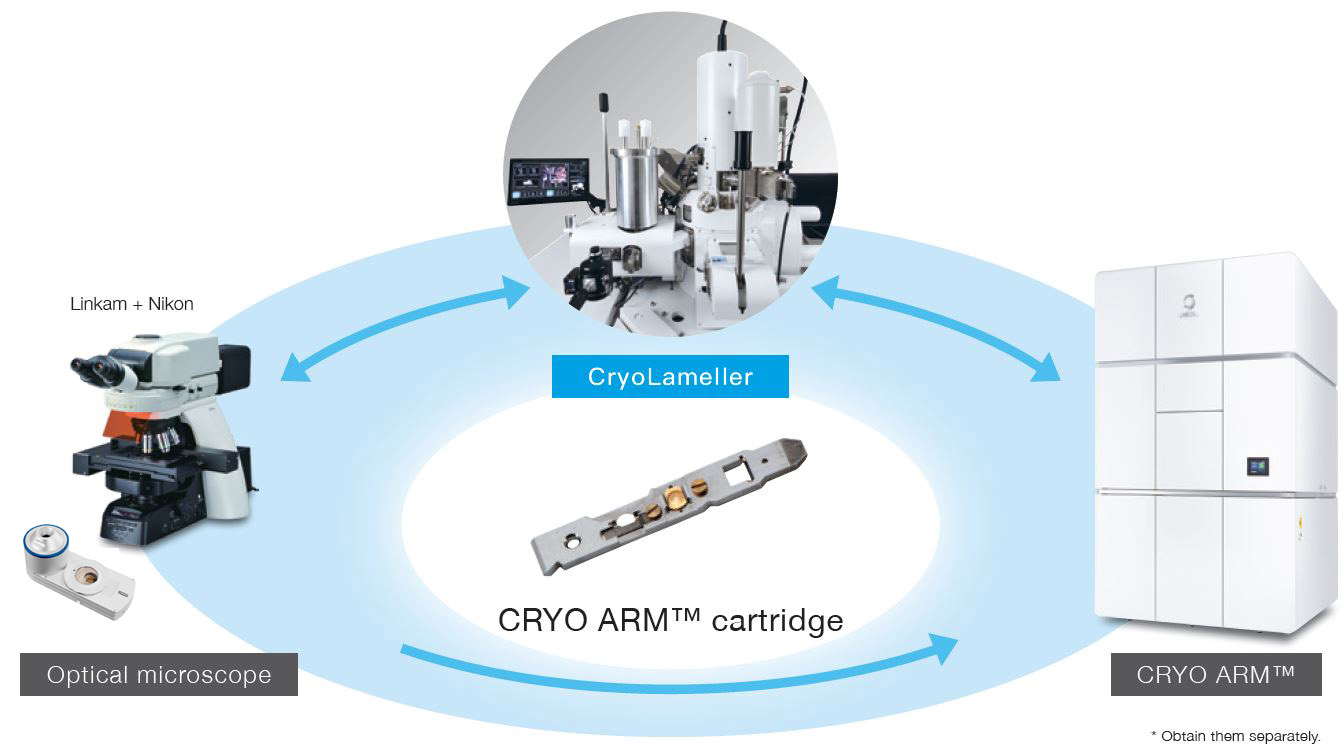

Cryo Specimen Transfer Using CRYO ARM™ Cartridge

After attaching a specimen mesh to the cartridge, it is no longer necessary to handle the specimen mesh using tweezers, so high-throughput specimen transfer can be performed.

Highly Stable Cooling Stage

The thermal conductivity cooling stage reduces stage drift and vibration caused by the cooling process and realizes steady TEM specimen preparation.

JEOL's Unique Anti-Contamination Device

With this newly developed anti-contamination device, ice contamination in the specimen chamber is reduced. Even during prolonged preparation of large specimen amounts, the device suppresses ice contamination to the fullest extent.

A cryo-CLEM workflow using the CRYO ARM™ cartridge can be constructed using a cryostage manufactured by Linkam Scientific Instruments* and an optical microscope manufactured by Nikon Corporation*. The stage coordinates of each instrument can be linked, so the orientation and position of the specimen can always be identified during specimen transfer between instruments.

Specifications

| SEM | |

|---|---|

| Landing voltage | 0.1 to 30.0 kV |

| Beam current | 1 pA to 300 nA |

| Image resolution | 1.6 nm (15 kV、WD 4 mm) 3.0 nm (2 kV、WD 8.5 mm) |

| FIB | |

|---|---|

| Accelerating voltage | 1.0 to 30.0 kV |

| Beam current | 1 pA to 90 nA |

| Image resolution | 4.0 nm (30 kV) |

| Cooling stage | |

|---|---|

| Cooling method | Thermal conductivity cooling |

| Coolant | Liquid nitrogen |

| Cooling temperature | Stage: -160 °C or lower Anti-contamination device: -180 °C or lower |

| Cooling retention time | 13 hours or more |

| Movement range | X:20 mm |

| Y:30 mm | |

| Z:4 to 40.5 mm | |

| T:-40 to 70° | |

| R:360° more (-190 to 190°) | |

Standard Configuration

| Conductive coating | Pt sputter coating system is built into specimen exchange chamber |

|---|---|

| Anti-contamination device | Incorporated in the SEM column and the specimen chamber |

Related Products

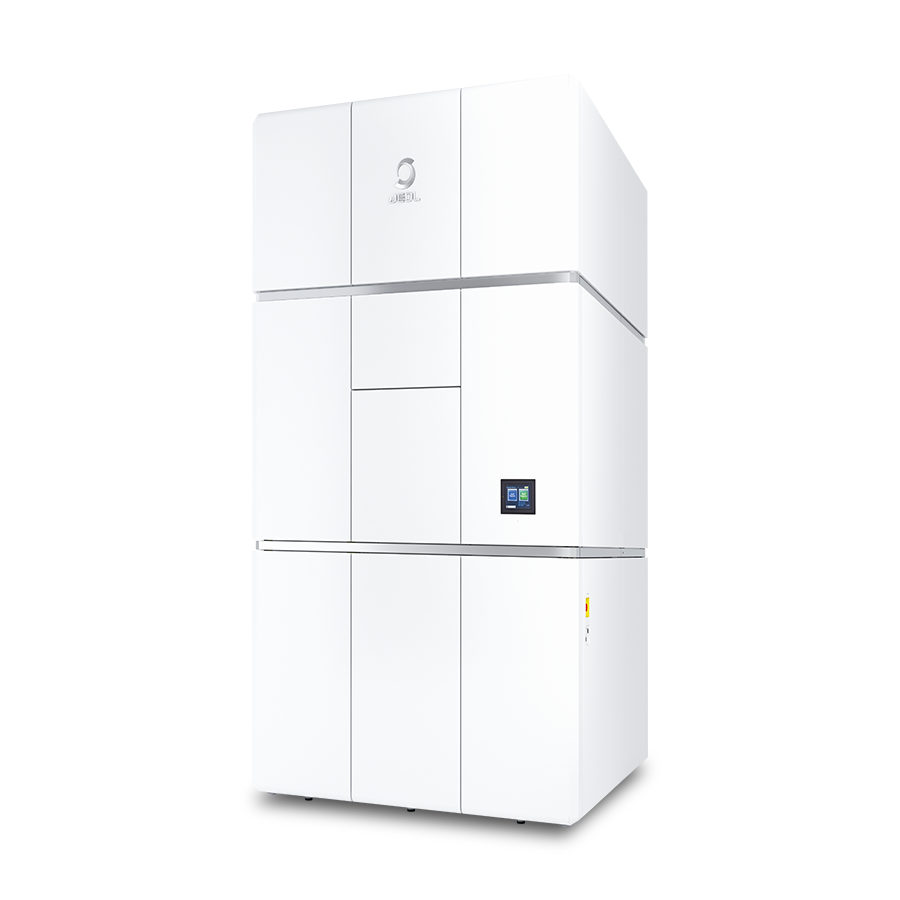

CRYO ARM™ 300 II (JEM-3300) Field Emission Cryo-Electron Microscope

CRYO ARM™ 300 II is a cryo-electron microscope that specializes in the observation of electron beam-sensitive specimens, such as protein, for single particle analysis, tomography and MicroED. This system offers improved stability, throughput and ease of use compared to the previous generation of cryo-EMs. Moreover, this is an all-in-one system that can handle everything from screening to data acquisition, allowing for more flexibility in operation at the customer sites to meet the needs of the facility. These improvements allow users to obtain high quality images by simple operations even for those who have never used an electron microscope before.

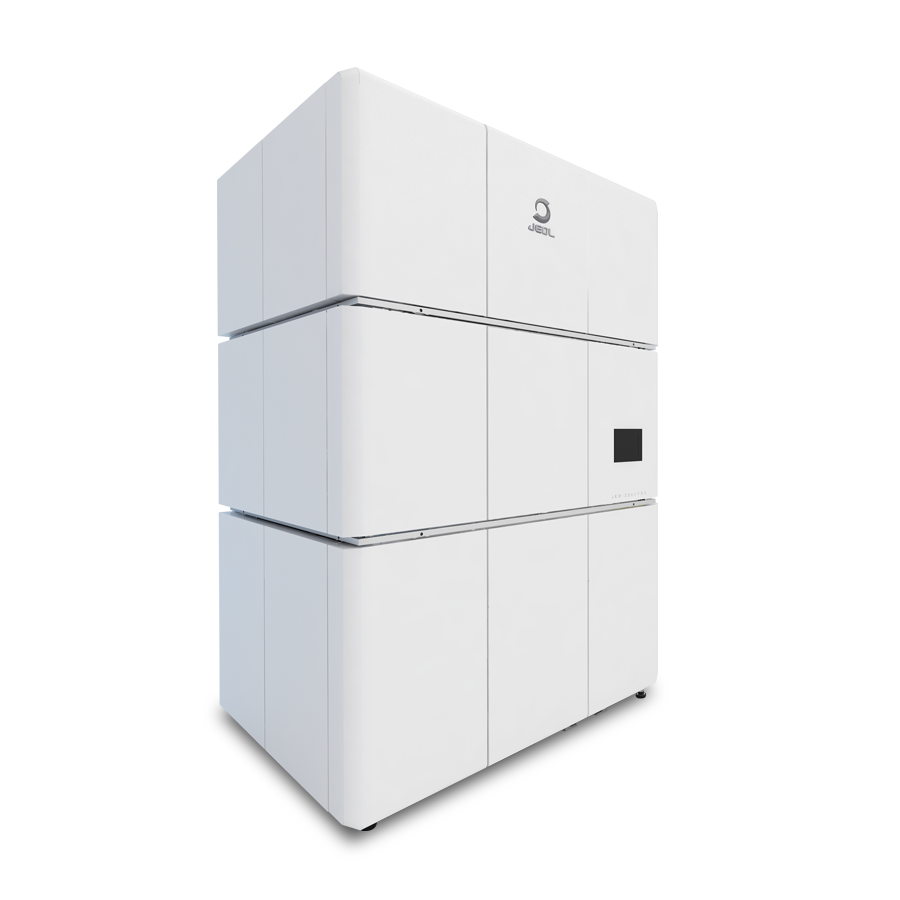

CRYO ARM™ 300 (JEM-Z300FSC) Field Emission Cryo-Electron Microscope

The JEM-Z300FSC (CRYO ARM™ 300), equipped with a cold field emission gun, an in-column Omega energy filter, a side-entry liquid nitrogen cooling stage and an automated specimen exchange system, is a cryo-electron microscope (cryo-EM) that enables observation of bio-molecules at cryo-temperature. The automated specimen exchange system features the storing of up to 12 samples. In addition, the system allows for the exchange of an arbitrary one or more samples, thus enabling flexible scheduling. Furthermore, the combined use of a newly-designed in-column Omega energy filter and a Hole-free phase plate dramatically enhances the contrast of TEM images of biological specimens.

CRYO ARM™ 200 (JEM-Z200FSC) Field Emission Cryo-Electron Microscope

Cryo-electron microscopy has been established as a method to enable observation of cells and biological molecules with no fixation and no staining. Owing to the recent rapid progress of hardware and software, this microscopy technique has become increasingly important as an atomic-scale structural analysis method. In addition, technologies that enable analysis of membrane proteins without crystallization have been developed, resulting in increased use of cryo-electron microscopy for drug discovery. Thus, installation of cryo-electron microscopes (cryo-EM) in universities and research laboratories is greatly accelerating. To meet the needs of cryo-EM users, JEOL has developed a new cryo-EM "CRYO ARM™ 200", which automatically acquires image data for Single Particle Analysis over a long period of time.

More Info

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.