Additive Manufacturing of Tungsten by Metal 3D Printer: The State-of-the-art Technology to Produce High Melting Point Metal

This column describes the state-of-the-art technology on additive manufacturing of tungsten and its challenges, along with how to overcome these challenges. In addition the current situation of tungsten fabrication including the issue of densification and cracks, the characteristics of major manufacturing methods and the latest trends.

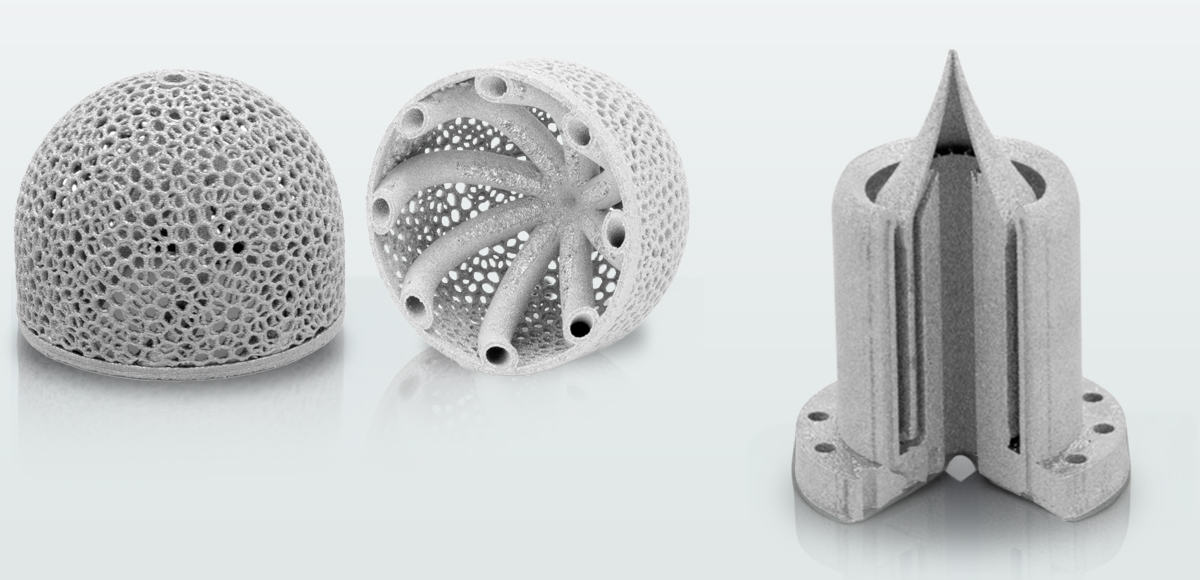

1. Improved degree of design freedom of tungsten by metal additive manufacturing machine (3D printer)

Tungsten has the highest melting point (3422°C) among metals. This extremely high melting point, as well as high thermal conductivity, high density, low linear expansion coefficient, and high strength, tungsten has been widely used in a variety of fields and industries such as lighting, high temperature furnaces, semiconductors, tools, medical equipment, etc. The usage includes filaments of incandescent lamps, material for high temperature furnaces, welding electrodes, cutting tools, medial catheters, and collimators for CT scans. However because of its characteristics, it is very difficult to process it using existing manufacturing and casting processes which results in constraint when designing a complicated part.

Recently, the challenge to manufacture tungsten without design restraints is becoming possible due to the progress of additive manufacturing technology, or 3D printing.

The area most focused on in manufacturing tungsten is for the practical application of a nuclear fusion reactor. With the nuclear fusion reaction, the core plasma reaches a temperature of hundreds of millions of degrees Plasma facing components, also known as PFCs are required to have an extremely high heat-resistance and sputter resistance (the property where the surface tends not to be scraped by the collision of plasma particles). Tungsten has been adopted by nuclear fusion projects in countries around the world as the leading candidate material. The wall for the reactor can be manufactured with existing methods, but these have some constraints in design and processing when a cooling channel is required to be built inside. Additive manufacturing by 3D printers alleviates these constraints and allows for manufacturing complex geometries and combining multiple parts into one. It is expected as the technology improves will allow further design freedom for nuclear fusion reactors.

Moreover, in the aerospace field, materials with extremely high heat-resistance and corrosion resistance are needed for the structure in a high temperature gas flow environment such as nozzles and thruster parts of rocket engines. Tungsten and its alloys are being considered as promising candidates for such usage due to its high melting point, high strength, and high density.

In medical fields, the demand for tungsten has been expanding as radiation shielding material in radiation therapy and diagnostic devices. In the electronic equipment field, it is also growing as high- density electrodes and heat dissipation structure materials.

Thus, the practical application of tungsten has been in demand to drive fundamental technologies that will support the future of humans such as energy, space, and the medical field. Manufacturing by 3D printing makes it possible to design and produce parts that were not possible before and bring about great advances in the practical application of advanced technology using tungsten.

2. Challenges for additive manufacturing (3D printing) of tungsten and technology for its resolution

Although additive manufacturing (3D printing) of tungsten is possible, it faces many technical barriers that make it challenging to print Tungsten successfully. It is important to understand these challenges in order to select the appropriate 3D printing technology.

Density

Part density is an important technical issue in the additive manufacturing of tungsten. It is extremely difficult to achieve full densification of tungsten because of its high melting point and high viscosity when molten. If the input energy during printing is too low, powders do not sufficiently melt, and pores remain. On the other hand, if the energy input is too high, another issue occurs such as the generation of gas pores due to the evaporation of molten metal. In other words, the key to improving density is to stably melt tungsten with the optimall energy.

Crack Generation

Another major issue in the additive manufacturing of tungsten is the generation of cracks (splitting). In the additive manufacturing of tungsten by LB-PBF (Laser Beam Powder Bed Fusion), a popular metal 3D printing method, causes great thermal stress inside the material due to cycles of rapid heating and cooling by laser during printing, causing the cracks. In addition, when oxygen enters inside the printed parts, micro voids called "nano pores" tend to form at the grain boundaries, creating weak points that make cracking more likely to occur.

To resolve these issues:

- Reduction of the temperature gradient by raising the pre-heated temperature before melting

- Beam scan strategy considerations

- Addition of alloying element

- Use of powder of consistent particle size distribution

Other resolutions are under investigation.

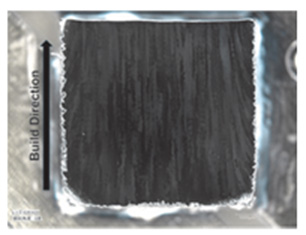

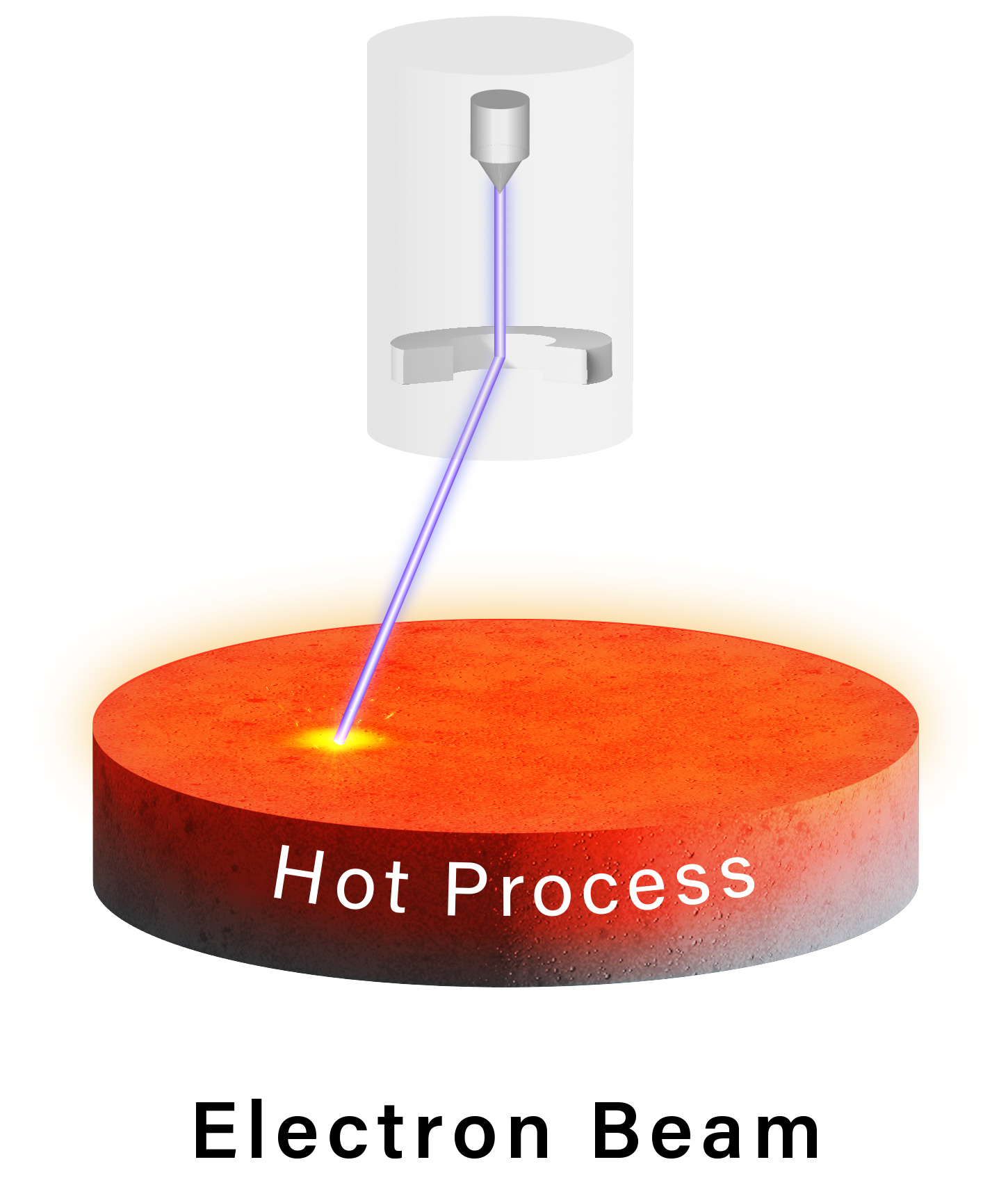

In addition, by selecting EB-PBF (Electron Beam Powder Bed Fusion) as the printing method, the temperature

gradient due to the hot process (process of pre-heating powder bed before starting the melting process)

will be lowered and reduce the cracks during printing.

If powders can be sufficiently molten by a high-power electron beam, pores can be reduced, resulting in

its superiority in densification.

The left figure shows a photo of a cross-section of tungsten parts printed by EB-PBF (15 mm cube). The cross-section shows a columnar oriented microstructure, enabling high-density (19.26 g/cm3) printing with no visible cracks.

Click here for a detailed explanation of the electron-beam metal 3D printer (EB-PBF).

3. Recent trend of 3D printing technology for tungsten

Because of its characteristics, it is extremely difficult to process tungsten by conventional machining and casting. Recently, additive manufacturing (AM) by 3D printing has been focused on as a measure to resolve the issues. As we introduced in Chapter 2, additive manufacturing by 3D printing also has issues such as densification and cracks.

Here, we present two topics showing the front line of tungsten 3D printing.

1) High performance tungsten parts due to Low-Temperature Spray-Dried Powder and Low-Energy SLM

2) Multimodal defect imaging of pure tungsten parts printed by EB-PBF

1) High performance tungsten parts due to Low-Temperature Spray-Dried Powder and Low-Energy SLM

Reference:

Zhang, Y., Wang, S., Liu, X., Sun, Z., Liu, H., & Huang, D. (2025). High - Performance Tungsten

Components via Low - Temperature Spray - Dried Powder and Low - Energy SLM: A Breakthrough for

Refractory Metal Additive Manufacturing. Engineering Reports, 7:e70426.

https://doi.org/10.1002/eng2.70426

Issue

The following issues arise, in particular with SLM (Selective laser melting method: same technology as LB-PBF)

- As tungsten is a metal with a high melting point, high power/ high energy are required to melt it by laser. However, excess energy can cause thermal stress due to rapid heating and cooling, and it tends to cause cracks. Moreover, if heating is too strong, components of tungsten and alloy evaporate, causing degradation of material quality.

- As tungsten has a high viscosity and high surface tension, the molten metal does not spread uniformly. As a result, part of the powder remains as powder, and gas enters in the metal to cause a pore, degrading the strength.

- If the shape and size of a particle of tungsten powder varies, laser irradiation will be uneven. In addition, if the powder does not flow smoothly, this causes an uneven area of powder when spreading powders Thus, the density by laser becomes uneven, causing variation in size accuracy and strength.

Resolution

-

Low-Temperature Spray-Dried Powder

Tungsten powders are typically produced by a high-temperature process such as plasma spheroidization. However, this process is costly, and it has the issue of difficulty in controlling the granularity and shape. If the liquidity and shape of powder are not good, uniform melting is not possible with SLM, increasing defects. Thus, in this study, we mix tungsten powder with water and binder to make it into a thick liquid(slurry), the powder can be scattered evenly. By spraying slurry and drying its extra moisture with hot wind, spherical powder with a property that is suitable for SLM process can be obtained.

-

Low-Energy SLM

Conventional SLM requires extremely high energy to melt tungsten. However, this causes thermal stress, cracks, and evaporation of the element. In this study, when the ratio between energy density (determined by the strength of the laser and conditions) and scanning speed (the speed of the laser runs) becomes 2 or lower, the temperature gradient was reduced, and cracking was prevented. According to the condition of this paper, it says that cracks were reduced by 78%.

2) Multimodal defect imaging of pure tungsten parts printed by EB-PBF

Reference:

Zhang, H., Carriere, P., Schneberk, D., Peverall, D., Amoako, E., Sprayberry, M., & Horn, T. (2025).

Multimodal defect imaging of pure tungsten components fabricated via electron beam powder bed fusion.

Journal of Materials Engineering and Performance, 34(10), 9140-9152.

https://doi.org/10.1007/s11665-025-10918-y

Issues

- EB-PBF is promising in AM fabrication of tungsten. However, if there are minor defects caused during the printing process or the presence of uneven areas inside the material, it is difficult to assure quality of the parts.

- Conventional methods for detecting failure are X-ray CT and optical inspection. It is difficult to precisely understand the inner structure, due to the limit of resolution and insufficient X-ray transmission into tungsten.

- EB-PBF environment is in high temperature and in vacuum, sensor fusion and real-time control are difficult.

Resolution

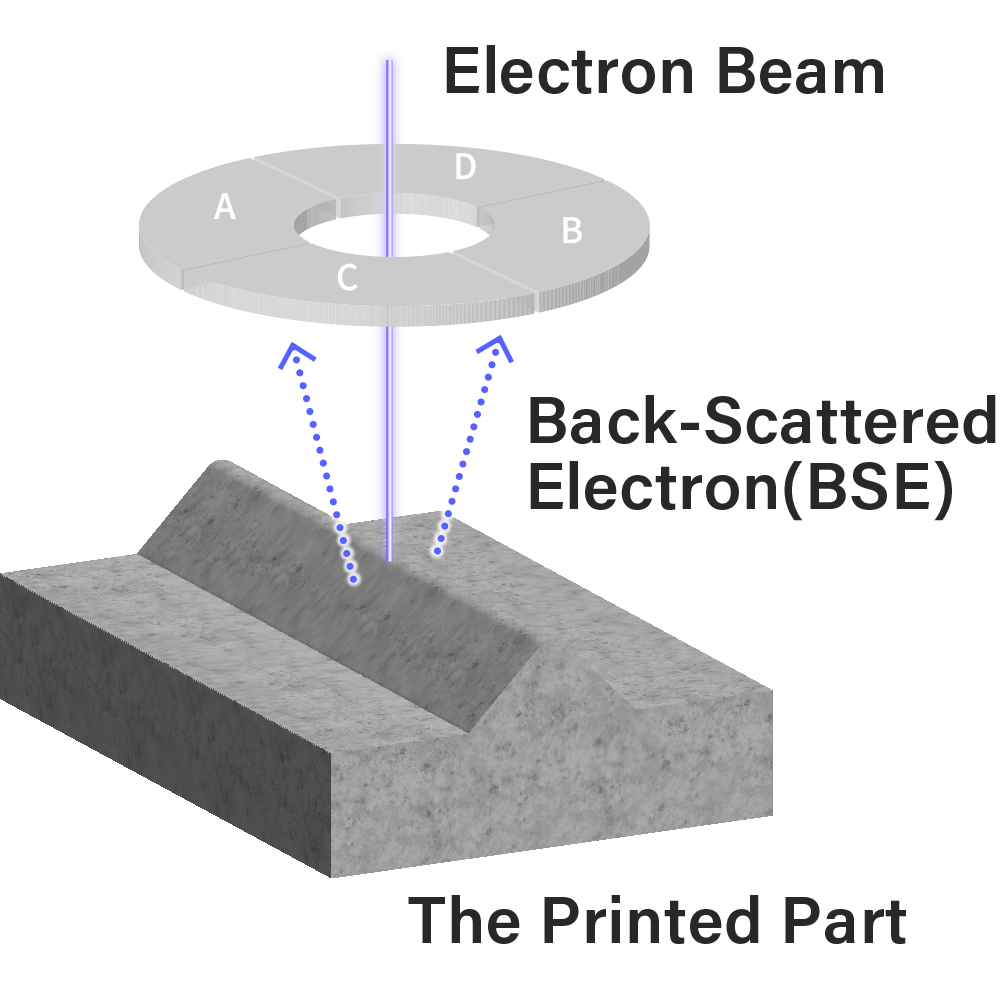

- As a result of the evaluation with the following 4 methods of "Electron Imaging", "Post-melt Near Infrared (NIR) Imaging", "Post-build X-ray Computed Tomography (CT) Imaging", and "Destructive Metallography Imaging", "Electron Imaging" has proven that it is likely to be the most suitable evaluation. Electron Imaging enables real-time evaluation of the quality of complicated parts, by collecting and analyzing the electrons emitted from the material, enabling to obtain the same effect as using an electron microscope during printing.

JEOL is under development of a BSE (Back-Scattered Electron) monitoring function which is only possible with expertise in electron microscopy. In-situ observation of roughness of molten surface is possible by trapping the BSE emitted from the electron beam. Technology of the electron microscope that detects backscattered electrons is utilized for quality control of the printed product, which is only possible with a electron beam metal 3D printer.

* Currently, the capability is limited only to Ti64 material. In the future, applications will include other materials such as tungsten.

4. Optimal Additive Manufacturing Method for Tungsten

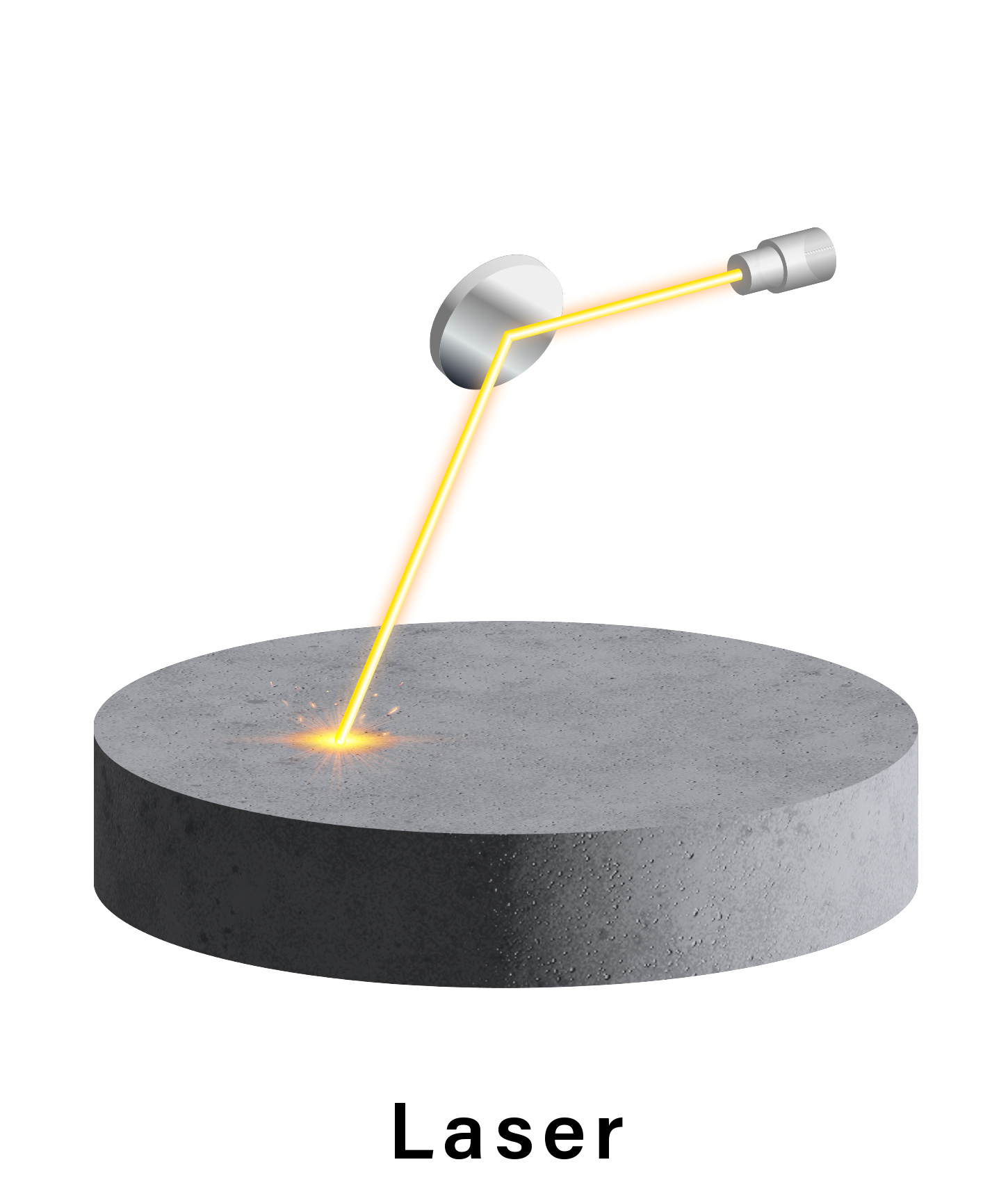

1. LB-PBF (Laser Powder Bed Fusion Method)

LP-PBF uses extremely thin layers (approx. 20 μm to 50 μm) of metal powder and melts the part cross section using the laser to make a part. The process is performed in an argon environment where oxygen concentration is low. It allows for the production of thin tungsten parts which are not possible with conventional methods. Additional work is being performed to print more complex parts using pure tungsten or tungsten alloy.

The quality of a product printed by LB-PBF greatly depends on the conditions such as the output of laser and scan speed, beam diameter, thickness of the powder layer, irradiation interval. Moreover, it is important what degree the laser makes contact with the powder and how well the laser is absorbed. These conditions largely affect the finish of the tungsten part. Compared with DED and EB-PBF, LB-PBF uses a smaller beam diameter, thus increasing the temperature gradient, increasing the cooling speed at the same time. Therefore, cracking due to temperature gradient tends to occur.

In addition, when powders are molten by a laser, a phenomenon of powder spattering or moving powder around the laser appears. This is called spattering (a phenomenon when powder is molten by a laser, the molten metal and powder spatter) and denudation (a phenomenon where powders around the laser are blown away). These can cause cracks and defects such as pores depending on the condition, and so, there are issues in densification. By understanding these characteristics and setting conditions properly, LB-PBF is utilized as an advanced manufacturing technology that allows for part production even with high melting point metals.

2. EB-PBF (Electron Beam Powder Bed Fusion Method)

EB-PBF is a manufacturing method for printing by melting powders layer by layer using an electron beam, instead of a laser. In order for stable irradiation of a high-energy electron beam, it is performed in a vacuum. In EB-PBF, the powder bed is pre-heated at a high-temperature(1000 to 1400°C for tungsten) during printing, and the electron beam is scanned at a high speed to partially and temporarily sinter powders to suppress repulsion between particles during charging.

Compared to LB-PBF, the part printed by EB-PBF has lower thermal stress. By rapidly moving the electron beam across the entire powder bed, local control of heat is possible, and the control of microstructure can be easier. Therefore, it is advantageous for stabilizing microstructure and controlling cracks. However, in the case of material of ultra-high melting points such as tungsten, a heat-resistant design that provides endurance for a high temperature environment exceeding 1000°C and consideration of beam scanning to avoid thermal cracks during printing are critical. It will require a properly designed and optimized EB-PBF printer to print these materials without cracks.

For these issues, the electron beam metal 3D printer of JEOL has achieved printing of a pure tungsten part by combining the unique heat-resistant design that can endure a high temperature environment, and beam scan control to avoid a thermal crack of tungsten. In addition, it is only JEOL Ltd. who succeeded in printing of a large tungsten part without any cracks at the moment.

5. Conclusion

Tungsten is a key material in fields such as nuclear fusion reactors, aerospace, as well as medical services. However, Tungsten was difficult to manufacture parts from by conventional processes. Additive manufacturing by 3D printing is a breakthrough for this constraint, greatly expanding the degree of design freedom.

On the other hand, the issue of LB-PBF is the shortage of densification due to cracks caused by rapid cooling. For this, EB-PBF (Electron beam powder bed fusion method) enables highly dense printing without cracks by relaxing the temperature gradient through a hot process. The electron beam metal 3D printer "JAM-5200EBM" of JEOL is a leading candidate for the practical application of tungsten fabrication.

In the future, the selection of the process suitable for usage and progress of quality-assuring technology will further accelerate the spread of tungsten 3D printing.

Related Products

JAM-5200EBM Electron Beam Metal AM Machine

We have developed the "JAM-5200EBM", an electron beam powder fusion (EB-PBF) metal 3D printer, by

applying the electron beam technology we have cultivated in electron microscopes and electron beam

lithography systems for semiconductor production.

The powder bed fusion method can produce a mold with higher density and strength compared to other metal

3D printer methods, and can mold complex shapes with high precision. The JAM-5200EBM does not require

the introduction of inert gas during molding, is equipped with a long-life cathode, and uses

high-definition automatic beam correction technology to ensure highly reproducible production. The

JAM-5200EBM is capable of molding high-melting-point metals and pure copper, which are difficult to mold

with laser printers.

6. Reference

Li, H., Shen, Y., Wu, X., Wang, D., & Yang, Y. (2024). Advances in Laser Powder Bed Fusion of Tungsten,

Tungsten Alloys, and Tungsten-Based Composites. Micromachines, 15(8), 966.

https://doi.org/10.3390/mi15080966

Howard, L., Parker, G. D., & Yu, X.-Y. (2024). Progress and Challenges of Additive Manufacturing of

Tungsten and Alloys as Plasma-Facing Materials. Materials, 17(9), 2104.

https://doi.org/10.3390/ma17092104

JEOL Ltd.

Since its foundation in 1949, JEOL has been committed to the development

of cutting-edge scientific and metrology instruments, industrial and medical equipment.

Today,

many of our products are used throughout the world and we are highly regarded as a truly global

company.

Aiming to be a 'top niche company that supports science and technology around the

world', we will continue to respond precisely to the increasingly sophisticated and diverse needs

of our customers.