Rapid Qualitative and Quantitative Analysis of Pyrolysis Oil Using GC–QMS

MSTips No.515

1. Introduction

Pyrolysis oil is obtained in the chemical recycling process, and its quality is evaluated using the GC–QMS method. In this method thermal decomposition products derived from a wide variety of feedstock polymers are detected, so identifying the types of polymers present and performing quantitative evaluation require considerable time. For identifying polymer types in resins, characteristic pyrolysis products obtained by pyrolysis (PY)–GC–MS are used as marker compounds; however, it remains unclear whether the same marker compounds can be applied for identifying polymer types in pyrolysis oil.

In this study, we used the JMS Q1600GC UltraQuad™ SQ Zeta to investigate the selection of marker compounds for the analysis of pyrolysis oil by the GC–QMS method, as well as a rapid identification method for polymer types in pyrolysis oil using these marker compounds. Furthermore, we also investigated a method for evaluating the composition ratios of polymer types based on the peak area ratios of the marker compounds.

JMS-Q1600GC UltraQuad™ SQ-Zeta

2. Experiment

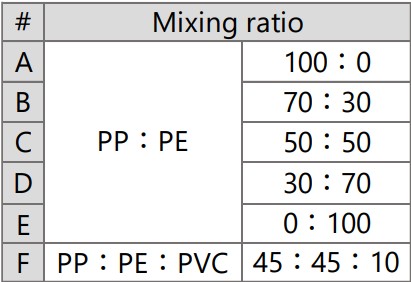

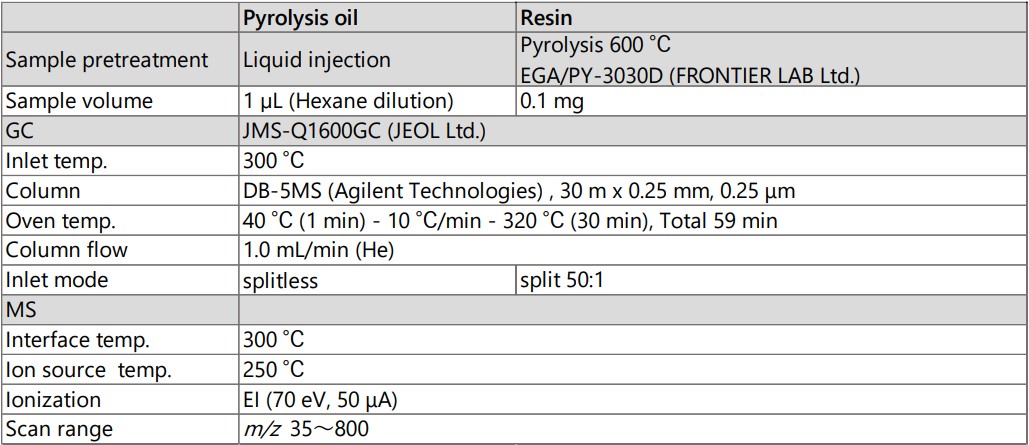

Pyrolysis oil generated from polymer types with the arbitrary mixing ratios shown in Table 1 and standard samples of Polypropylene (PP), Polyethylene (PE), and Polyvinyl Chloride (PVC) resins were used as the sample. GC-QMS was used for the analysis of pyrolysis oil, while PY-GC-QMS was used for the analysis of resins. The target analysis function of the integrated analysis software (msFineAnalysis iQ, JEOL Ltd.) was used for rapid detection of marker compounds. This function detects peaks from the extracted ion chromatograms (EIC) based on information such as the molecular formula or fragment composition of the target compounds and confirms the presence of compounds by integrated determining whether the detected peaks correspond to the target compounds. Measurement conditions of GC-QMS and GC-QMS are shown in Table 2.

Table 1 Sample (Pyrolysis oil)

Table 2 Measurement Conditions

3. Results

3.1 Selection of Marker Compounds for Polymer Identification in Pyrolysis Oil

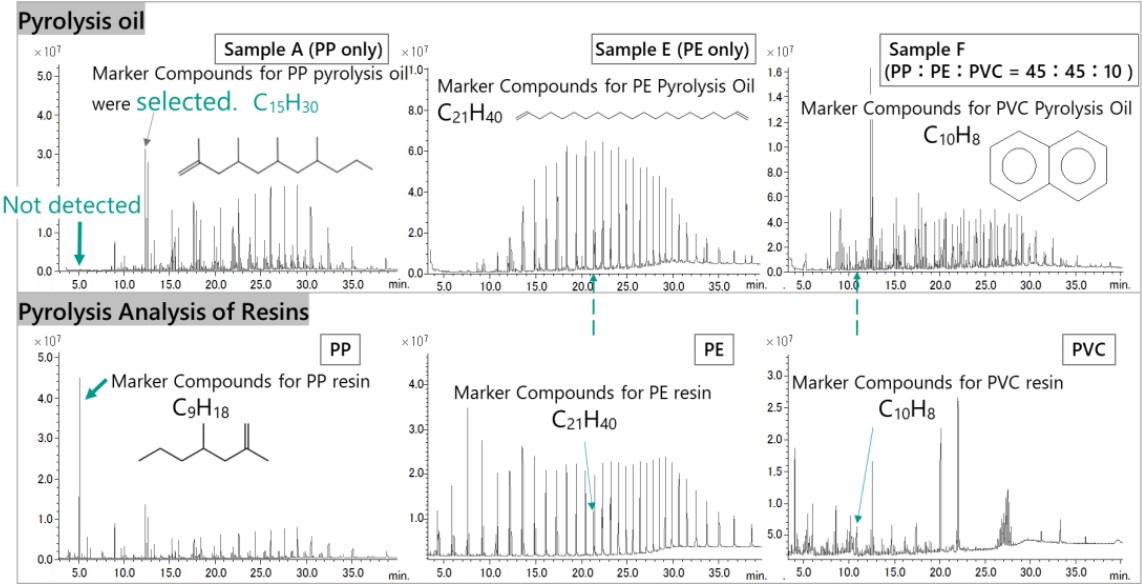

Figure 1 shows the total ion chromatograms (TICC) of pyrolysis oil measured by GC-QMS and of resins measured by PY-GC-QMS. 2,4-Dimethyl -1-heptene (C9H18), a common1) marker compound for PP resin was not detected in the pyrolysis oil, and since it is a low-boiling component, it is considered to have volatilized during the collection and storage of oil. Therefore, 2,4,6,8-tetra methyl-1-undecene (C15H30) was selected as the marker compound for identifying PP in pyrolysis oil. For PE and PVC, the marker compound 1,20-heneicosadiene (C21H40) and naphthalene (C10H8) identified by pyrolysis analysis (PY-GC-MS) was similarly detected in the pyrolysis oil and were therefore selected as the marker compounds for each resin.

References 1) A. Watanabe, BUNSEKI KAGAKU, 73, 6, 251-263 (2024).

Figure 1 Pyrolysis oil : TICCs of samples A, E, and F (top) / Resins : TICCs of PP, PE, and PVC resins (bottom)

3.2 Rapid Identification of Polymer Types in Pyrolysis Oil Using Marker Compounds

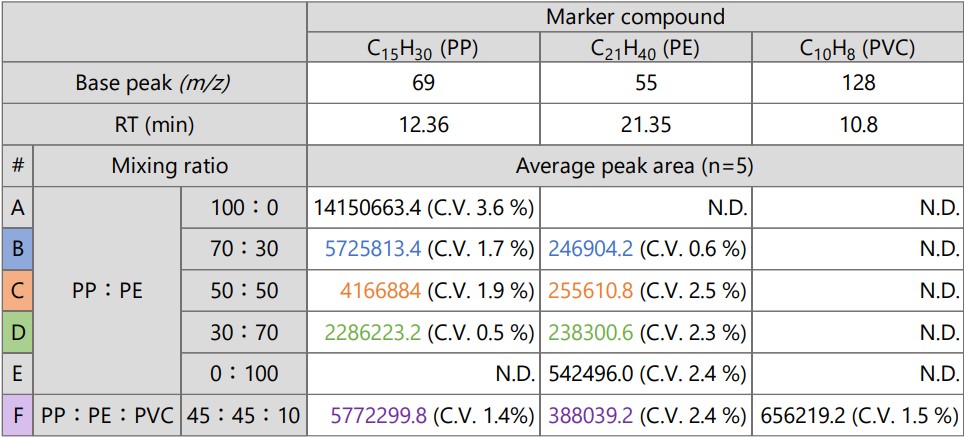

Table 3 shows the peak area values and C.V. obtained from the EIC (base peak m/z) of the marker compounds shown in Section 3-1.

The results demonstrated that the polymer species in pyrolysis oil containing multiple polymers could be rapidly identified using marker compounds.

Table 3 Peak area values and C.V. (n=5) of marker compounds detected in each sample

3.3 Evaluation of polymer composition ratios based on peak area ratios of marker compounds

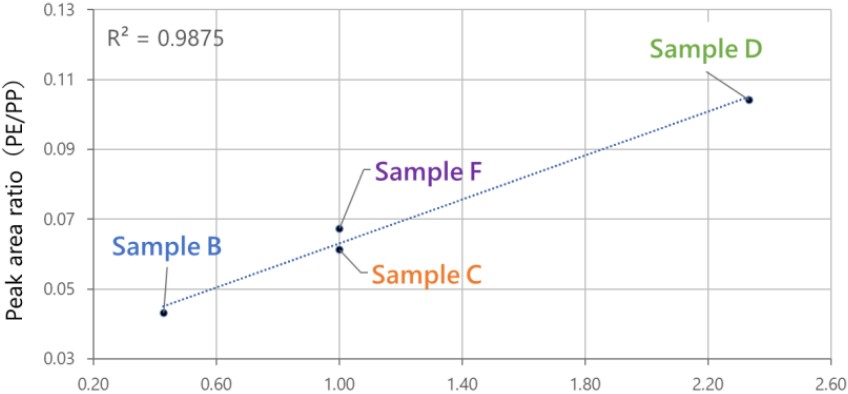

Figure 2 shows plots for samples B, C, D, and F, with the polymer composition ratio of PP and PE on the x-axis and the peak area ratio of PP and PE on the y-axis. The results indicate a correlation between polymer composition ratio and peak area ratio, demonstrating that the composition ratio of polymer species in pyrolysis oil can be evaluated using GC-QMS.

Figure 2 Correlation between polymer composition ratio (PE/PP) and peak area ratio of marker compounds (PE/PP)

4. Conclusion

In the analysis of pyrolysis oil using GC-QMS, low-boiling components of the pyrolysis oil may volatilize during collection and storage. Taking this into account and appropriately selecting marker compounds allowed rapid identification of polymer types and evaluation of their composition ratios.

Solutions by field

Related products

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.