This product is no longer available.

If you would like to know the latest information about your preferred product or to find out more about alternatives, please click on the link below. We hope you will continue to use our products.

New high-speed and fine milling modes achieves even higher throughput of high-quality cross sections.

Intermittent milling mode is standard, simplifying the handling of specimens susceptible to heat damage.

Improvements to facilitate processing of a wide range of materials include:

Features

The evolution of the Cross Section Polisher (CP)

High-speed processing achieved with a new ion source

Reduced specimen damage with fine milling & intermittent mode

A “Quick Start” function reduces total process time

Charge prevention IN-situ coating function (option)

IB-19500 Features

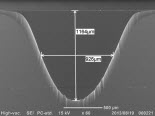

★ New high-speed ion source

Delivers 500μm/h (8kV/2 hour average)

Processing results for 8kV, 2 hours (Si)

★Selectable finishing

By setting the fine milling parameters after high-speed processing

ion damage to the cross section can be reduced.

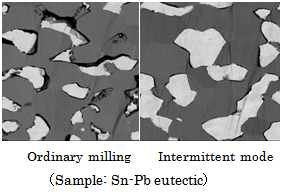

★Damage reduction with intermittent mode

Intermittent milling mode is standard, allowing heat damage of specimens to be reduced.

The intermittent setting can be made in 1 second increments.

More Info

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.