TP series

RF Induction Thermal Plasma

Generates thermal plasma at about 10000 degrees by high-frequency induction through a physical / chemical reaction process, enabling nanoparticle synthesis and thick film synthesis (film formation)

Features

Principles・Features

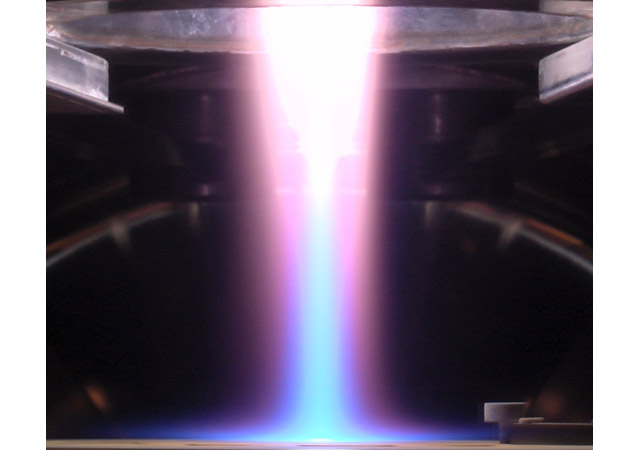

The radio-frequency thermal plasma operates at atmospheric pressure, or in a low-pressure environment close to atmospheric pressure, concentrating the high-frequency power at a specific location to spontaneously generate an approximately 10,000 degree plasma from various gases using Electromagnetic induction.

This thermal plasma is an area of the arc discharge. By introducing materials (powders, gas, fluids) into the plasma it is possible to induce vaporization, melting, dissociation, and chemical reactions for applications such as nano-particle synthesis, powder spherodization and reaction, film formation, and dissociation of harmful gases.

Compared to the direct current (DC) arc discharge, a larger plasma volume can be obtained

The gas flow is also better than that of the DC plasma. Since the flow rate is an order of magnitude slower, it is possible to adequately heat the materials to induce the desired reactions.

Since there are no electrodes, there is no contamination from electrode materials, enabling high-purity processing.

A wide range of gases can be used, including oxidative, reductive and corrosive gases

Fine particles can be created, with a fineness on the nano-order, a level beyond the capability of mechanical pulverization

Being able to make use of the reactions of high-energy chemical species, such as atoms, ions, excited molecules and radicals, opens the possibility to create new substances and materials.

Device outline

Incorporates controllability and matching circuits optimized to the load of the high-frequency oscillators of the radio-frequency thermal plasma torch, along with abnormal discharge countermeasures and an industry-leading power source efficiency

Product line-up(Nominal output):6kW ,35kW ,100kW ,200kW

*A 300kW type has also been produced

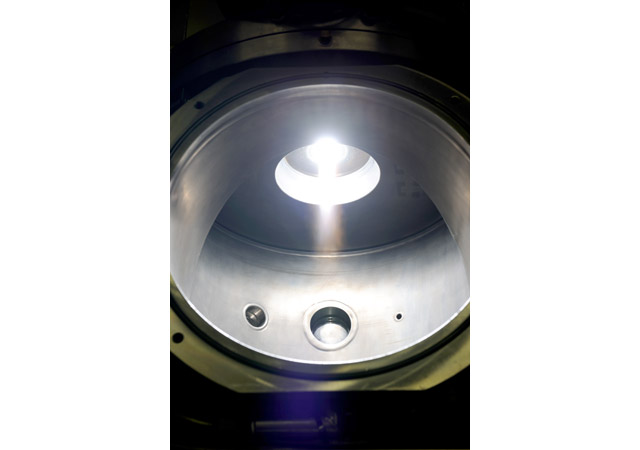

Plasma torch

There is dedicated plasma matching for each of the high-frequency oscillation mechanisms.

High-density plasma torch diameter and formation

Two-layer cooling water piping is used, with an inner pipe made from a ceramic that is more durable than the quartz pipes ※ (patented). This enables stable operation over a long period of time, from low pressures to atmospheric pressure.

Exceptional durability in comparison to the quartz pipes

We have also been developing a hybrid plasma torch that combines both direct current (DC) and radio-frequency (RF) methods. The features of the hybrid method include;

A radio-frequency plasma assist effect by overlapping the direct current plasma jet directly on top of the radio-frequency plasma

For nano-particle synthesis, it is possible to pre-heat the raw materials using the DC plasma, enabling more efficient vaporization (smaller particles).

System

We offer systems to suit applications including nano-particle formation, film deposition, and research applications

The hot plasma generator (component) is also available.

Application

Application TPseries

Gallery

Related Products

Related Products

TP-99010FDR Fine Powder Feeder

A volumetric feeder device using gas to transport powder through tubing

More Info

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.