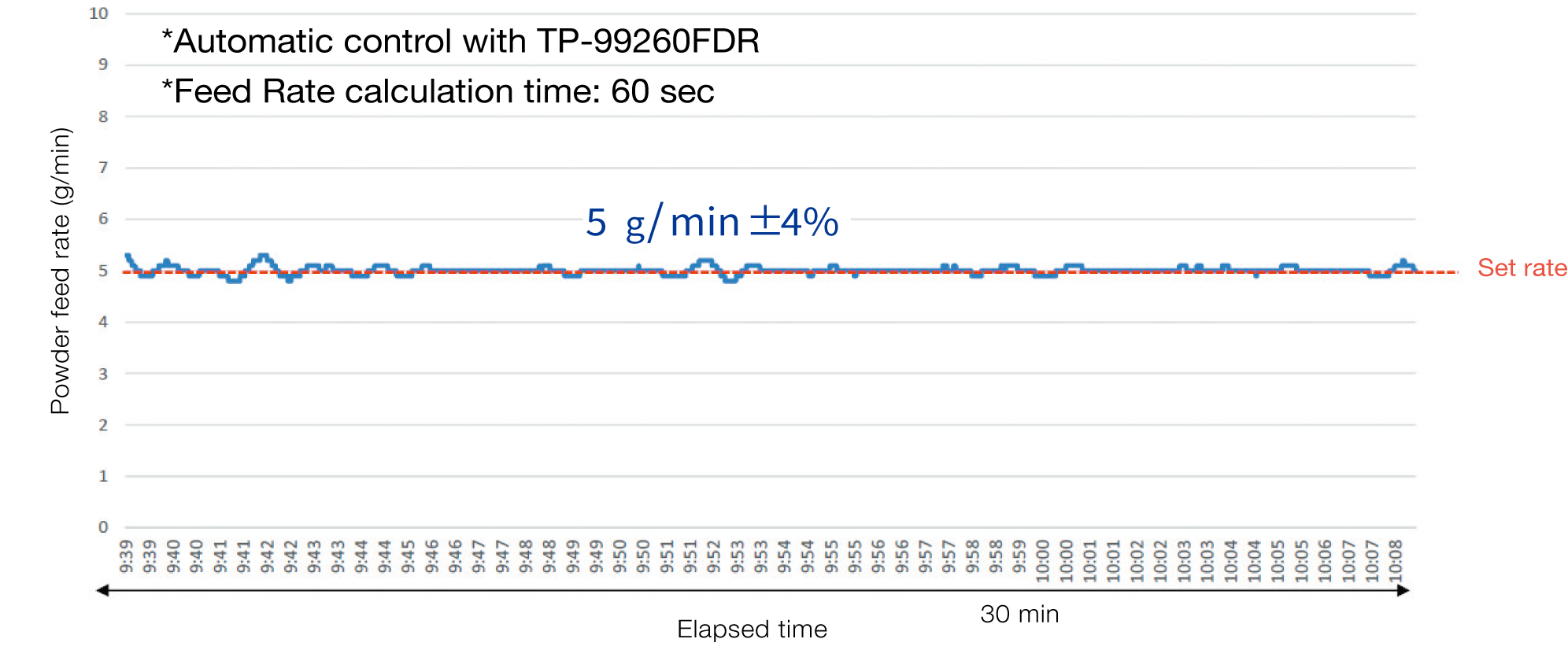

Automatic powder feed rate control function has been added for more stable powder feeding.

External control is also available.

Features

Continuous quantitative feed of particles with a few micron or less with high cohesive and poor fluidity is possible with automatic control.※1

Powder feed rate is around 0.1 to 200 g/min or more by changing option items.※2

Thanks to the sealed structure, it is possible to feed into reduced-pressure atmosphere.

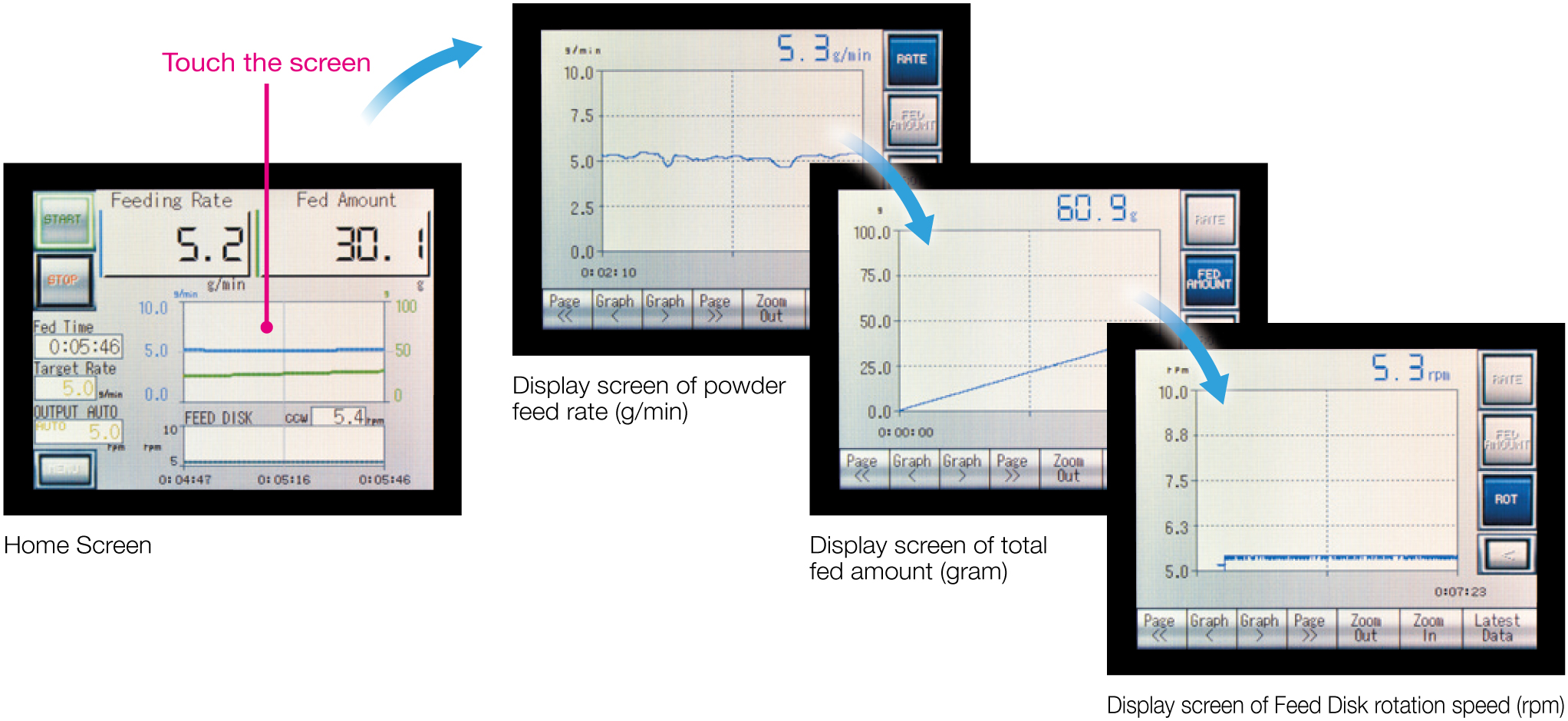

Can monitor and record the real-time powder feed rate, the total fed amount and the Feed Disk rotation speed. Data can also be saved to a PC via LAN.

Not only single powder but also mixed powder can be fed continuously without changing mixing ratio.

- Manual control is also available.

- The feeding condition differs according to the powder type, size, shape, weight and state. The feed rate range that can be set vary with optional items such as gears.

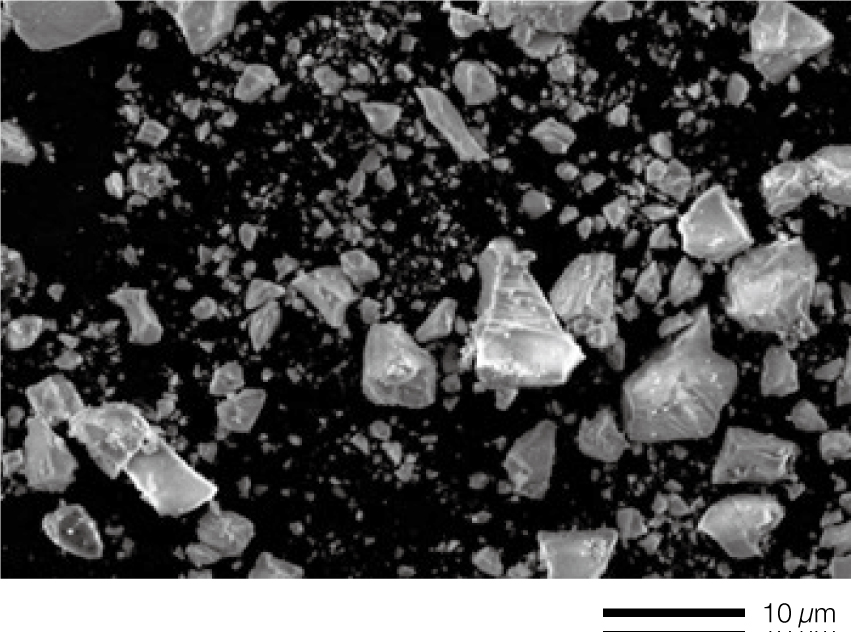

Yttria Stabilized Zirconia(YSZ) powder

(Average particle diameter: approx. 1 μm)

Specifications

Specifications

| Item | Contents |

|---|---|

| Powder particle size | Approx. 0.1 to 100 μm or more ※1 |

| Powder feed rate | Approx. 0.1 to 200 g/min or more ※2 |

| Feed method | Table type, gas carrier |

| Adaptive gas type | Ar, N2, Air |

| Gas flow control system | Not included |

| Gas purity | 99.9% or more |

| Gas pressure | Max. 0.45 MPa / Normal use 0.3 MPa or less ※3 |

| Gas flow rate | 1 to 20 L/min or more ※4 |

| Leak rate | +2 kPa or less in 10 minutes ※5 |

| Hopper capacity | Approx. 500 mL ※6 |

| External control signal |

Contact outputs

|

Contact Inputs

|

|

Analog inputs

|

|

| Size / Mass (Powder feeder) | Approx. 280 mm(W) × 211 mm(D) × 541 mm(H) / Appr ox. 21 kg ※7 |

| Size / Mass (Contoller) | Approx. 480 mm(W) × 300 mm(D) × 200 mm(H) / Appr ox. 12 kg ※8 |

| Input power / Grounding | Single-phase 100 to 120 V ( -15 to +10% ), 50/60 Hz, 7 A, 100 Ω or less (1 terminal each for the feeder and the contr oller) |

- The range of powder particle size that can be fed differs depending on the type, shape and state of the powder. We have experienced 700 to 900 μm powder.

- The feeding rate range differs depending on the powder type, particle size, shape, state, optional items configuration and carrier gas conditions.

- We recommend the use of Mass Flow Controller, because the gas pressure needs to be constant for stable feedeng.

- Depending on the tube diameter and length, 20 L/min may not be supplied. If the gas flow is too low, powder may not be fed. Gas supply utilities need to be provided by customer.

- It changes with the consumption degree of O-rings. O-rings need to be replaced regularly.

- The capacity can be increased by mounting optional hoppers.

- Cables are not included in the weight.

- Depth dimensions do not include gas piping.

Required optional items

| Item | Contents |

|---|---|

| Suction Nozzle Unit | Pipe diameter: 1 mm type / 2 mm type / 3 mm type / 4.6 mm type |

| Feed Disk | Groove width: 1 mm type / 3 mm type / 5 mm type / 10 mm type ※9 |

- Feed Disks are also available Special - shaped.

Options

| Item | Contents |

|---|---|

| Convex Flange Unit | Loosen highly cohesive powder that has solidified in the groove of the Feed Disk. |

| Gearbox | The ratio of Feed Disk:Rotor can be changed to 1:1 and 1:3. (Standard: 1:4) |

| Additional Hopper | 1 L type (Total approx. 1.5 L) / 7 L type (Total approx. 7.5 L)

|

| Internal View Window | Can visually observe the remaining state of the powder in the hopper. |

※Specifications subject to change without notice.

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.