BS/JEBG/EBG series

Electron Beam Source

Electron beam sources / power supplies for electron beam deposition used for creating various types of films, including optical films and electrode coatings.

Features

Features of the electron beam deposition method

The thermal efficiency is quite good due to the heating from direct irradiation of the electron beam onto the deposition material. It is possible to vaporize a variety of materials, including high-melting point metals, oxides, compounds and sublimation materials.

Since the deposition material is directly heated in the water-cooled crucible(*), there is no reaction of the boat or crucible as with resistance heating or inductive heating methods.

A hearth liner is used in some cases

Since high-speed output control is available, it is possible to precisely control the film thickness.

In comparison to sputtering and CVD methods, the speed of the film creation is a main feature. This is also useful for creating thick coatings of 1µm or more.

Features of JEOL electron beam sources

[ Oxides ]

Features a beam incidence angle perpendicular to the deposition material, and a high energy-density beam spot that is nearly a perfect circle. Since the high-speed sweeping function is standard, it is suitable for deposition onto sublimation materials and oxides with low thermal conductivity and high melting point. Can obtain excellent melted remains, enabling uniform, reproducible film thickness distributions over a wide area.

[ Metals ]

Selection from a wide range of crucibles is available, enabling multi-type, large-volume, and high-rate deposition. There is also an electron gun compatible with the lift-off process to limit the temperature increase during film creation.

[ Alloy/ Multi-layer coatings ]

Alloy and multi-layer coatings can be created by placing different materials into adjacent 2 or 3-pockets crucibles and performing simultaneous 2 or 3-source deposition using the special sweep controllers.

Related product links

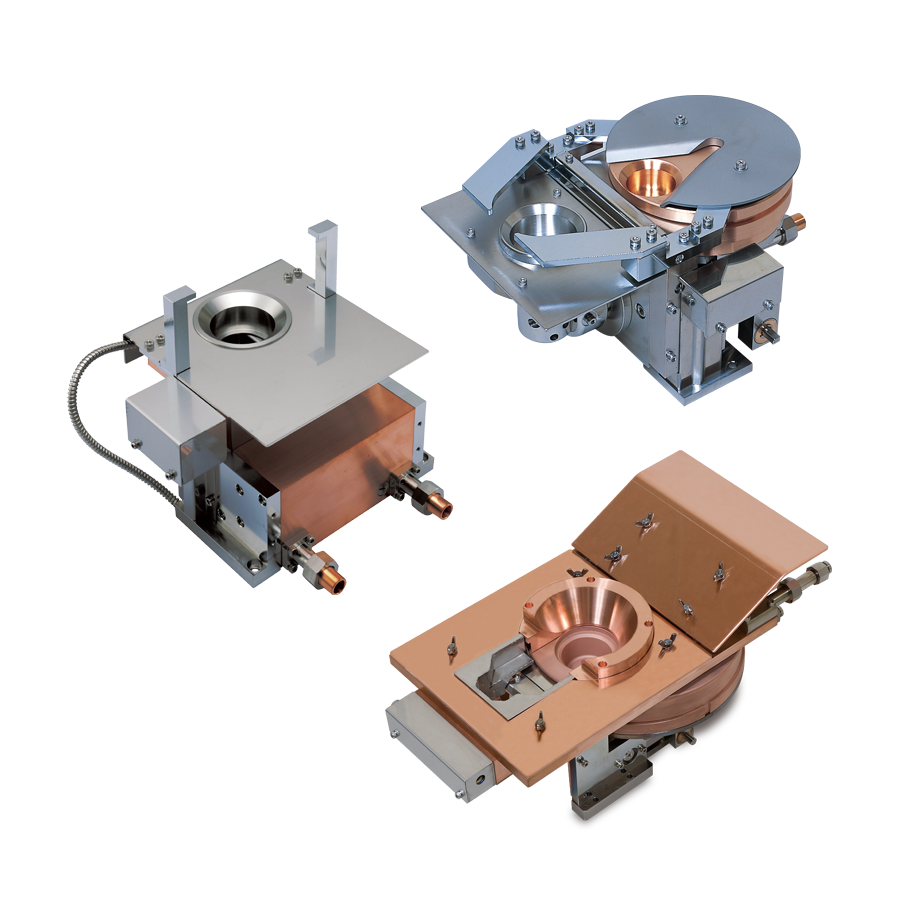

BS-60211DEM/BS-60210DEM Electron Beam Source

Specifications

| Model | Max. output | Deflection angle |

Filament | Beam sweep | Crucible | Oxides | Metals |

|---|---|---|---|---|---|---|---|

| BS-60070DEBS | 6.4kW | 270° | U-shaped (long-life) |

High-speed scanning |

none※2 | ◎ | ○ |

| BS-60060DEBS | 6.4kW | 270° | none※2 | ◎ | ○ | ||

| BS-60050EBS | 10kW | 270° | none※2 | ◎ | ○ | ||

| BS-60040VDGN | 10kW | 270° | none※2 | ◎ | ○ | ||

| BS-60030DGN | 10kW | 270° | none※2 | ◎ | ○ | ||

| EBG-102UB6S | 10kW | 180° | Spiral | 12cc×6 spot | ◎ | ○ | |

| EBG-102UB4S | 10kW | 180° | 12cc×4 spot | ◎ | ○ | ||

| JEBG-102UH0 | 10kW | 180° | none※2 | ◎ | ○ | ||

| BS-60210DEM +BS-60140H4H |

10kW | 270° | Straight coil (Long-life) |

Medium speed scanning |

40cc×4 spot | △ | ◎ |

| BS-60210DEM +BS-60150H6H |

10kW | 270° | 40cc×6 spot | △ | ◎ | ||

| EBG-203UB6S | 20kW※1 | 270° | Spiral | High-speed scanning |

12cc×6 spot※3 | ○ | ◎ |

| EBG-203UB4H | 20kW※1 | 270° | 12cc×2 spot 28cc (half-sphere)×2 spot |

○ | ◎ | ||

| JEBG-203UA0 | 20kW※1 | 270° | none※4 | ○ | ◎ | ||

| JEBG-303UA | 30kW※1 | 270° | none※5 | ○ | ◎ |

Since the maximum output of the EB power supply is 16 kW, the actual maximum output that can be used is 16 kW.

Available as special order ⇒12cc×4 or 6 spots, etc.

Crucible well shape variation available ⇒ 28cc(φ45×20h)×6 spot, 51cc(φ60×20h)×3 spot, etc.

Available as special order ⇒40cc(φ50×25h)×4 or 6 spot, 114cc(φ75×30h)×1 spot , etc.

Available as special order ⇒114cc(φ75×30h)×1 spot, φ34×20h×3 holes in 1 pocket (for simultaneous deposition), φ70×30h×4 spot, etc.

Please inquire about crucible specifications

Catalogue Download

BS/JEBG/EBG series Electron Beam Source

Related Products

BS-60060DEBS Electron Beam Source

An electron beam source providing the ultimate minimization of the backscattered electron dose to the substrate. All the features and performance of the BS-60050EBS, with the addition of a longer-life filament and improved reproducibility.

BS-60211DEM/BS-60210DEM Electron Beam Source

Electron beam source for vacuum metal deposition suitable for low-temperature process such as lift-off process for electrode film applications.This e-beam source is equipped with a backscattered electron trap and designed to prevent cross-contamination.

More Info

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.