Electron beam source for vacuum metal deposition suitable for low-temperature process such as lift-off process for electrode film applications.

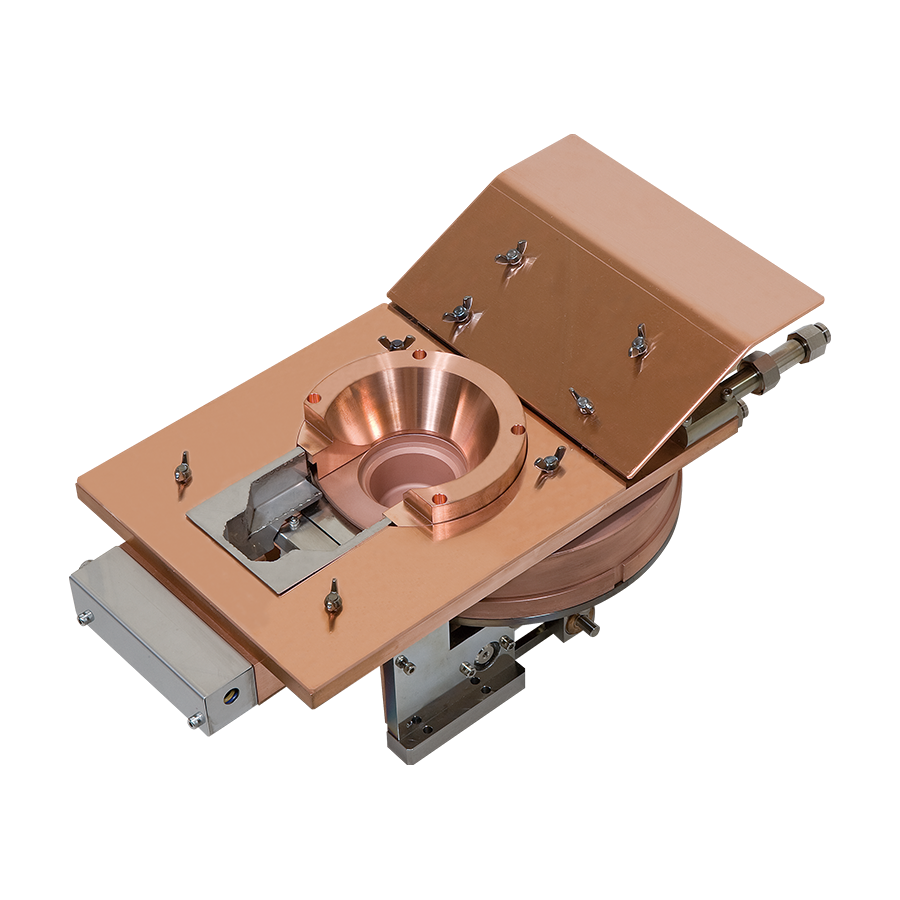

This e-beam source is equipped with a backscattered electron trap and designed to prevent cross-contamination.

Features

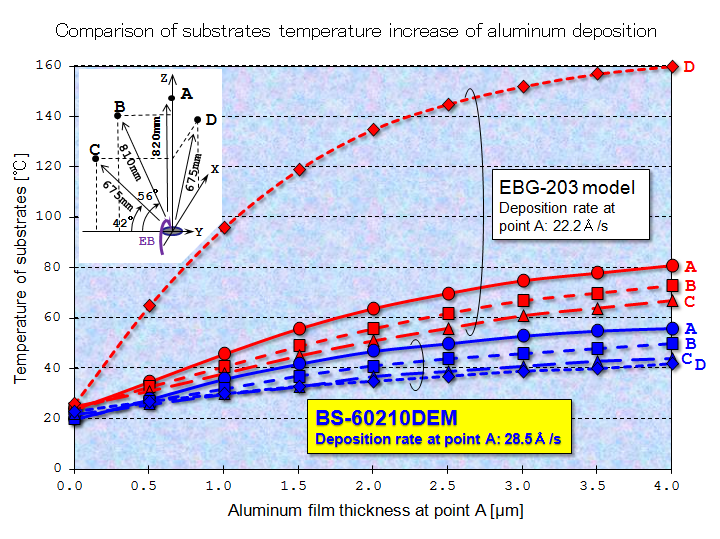

Low-temperature and low-damage deposition

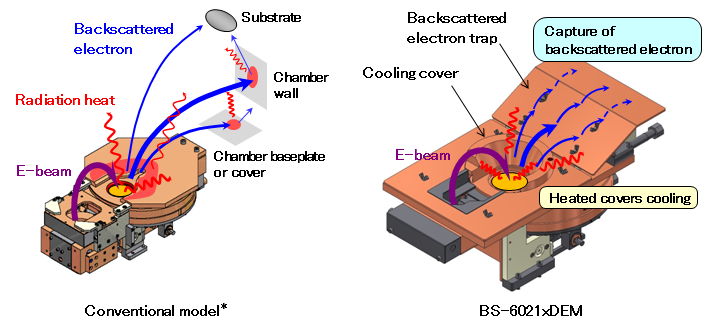

A high-efficiency backscattered electron trap is equipped in the standard configuration, making it possible to capture diffusing reflected electrons.

And enhanced cooling effect of the e-beam source can lower radiation heat from around evaporation source.

These two effects enable to reduce the temperature increase of the substrates during high-rate deposition of metallic substances.

And also can reduce the damage to the substrates and/or the under layers caused by reflected electrons irradiation.

Conventional e-guns cause substrate temperature rise during vacuum deposition due to thermal effect of backscattered electrons and radiation heat from around evaporation source.

Chamber wall, baseplate and covers are heated by hitting backscattered electrons and then secondary and tertiary radiation heat arise from there.

When backscattered electrons irradiate substrates directly, the substrates temperature increase highly.

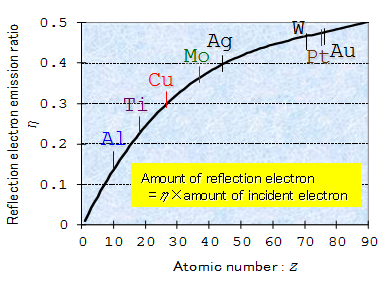

Reflection electron emission ratio

Higher atomic number material reflects more electrons.

Gold and platinum emit nearly half electrons.

The energy of reflection electron is almost the same as incident energy.

When the accelerating voltage of the e-beam source is -10kV, the energy of the reflected electron is approx. 10kV.

Thick-film deposition / Multi-layer coating

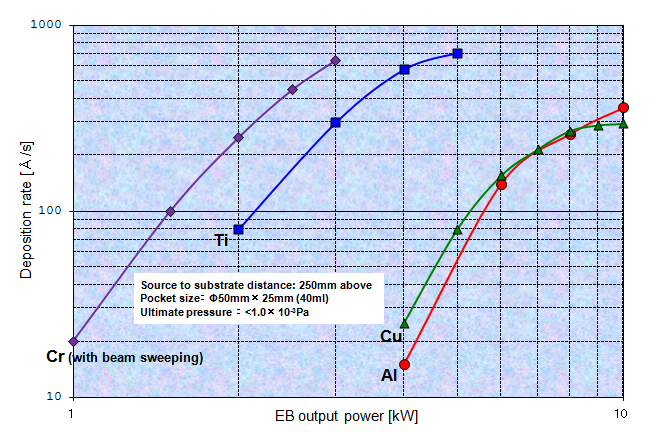

Optional large capacity 40 ml crucibles (4-pocket or 6-pocket) enable thick-film deposition and/or multi-layer coating by using several evaporation materials.

Cross-contamination prevention

Prevent contamination of evaporated material from inflowing into adjacent pockets.

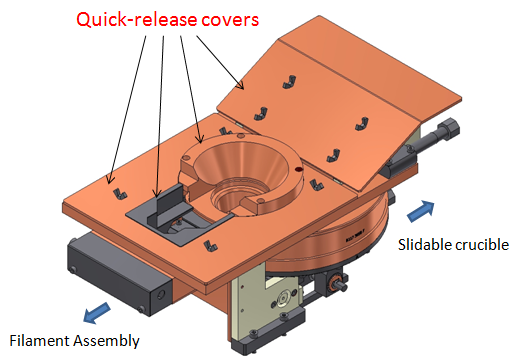

Easy maintenance

Each covers can be taken off easily, therefore cleaning of deposited evaporation materials doesn’t take a lot of trouble.

Optional crucibles can be taken off and separated from e-gun. And upper hearth is exchangeable.

Filament lifetime is long and filament exchange is also easy.

Deposition rate example of metallic materials

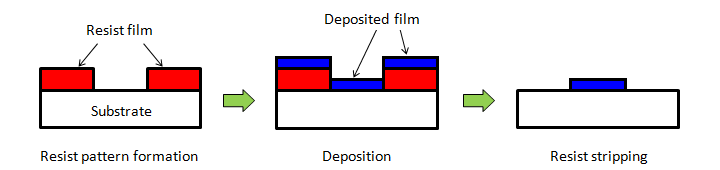

Lift-off process

Film formation process flow of lift off

Able to keep substrate temperature during vacuum deposition at less than 100 degrees C.

Thus, can prevent deformation of resist pattern, making it possible to improve the yield ratio of lift-off process.

Application examples: Electrode film formation of LED, SAW filter, Power semiconductor, MEMS, etc.

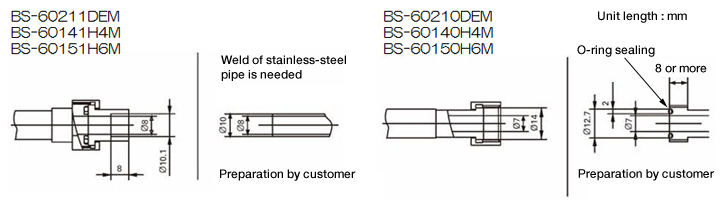

Specifications

| BS-60211DEM | Electron beam source (maximum output 10 kW) |

|---|---|

| BS-60210DEM | Electron beam source (maximum output 10 kW) |

| BS-60141H4M | 40ml (Φ50mm×25mmH) × 4-pocket crucible |

| BS-60140H4M | 40ml (Φ50mm×25mmH) × 4-pocket crucible |

| BS-60151H6M | 40ml (Φ50mm×25mmH) × 6-pocket crucible |

| BS-60150H6M | 40ml (Φ50mm×25mmH) × 6-pocket crucible |

The model differences of the electron beam sources and crucibles are only cooling water piping joint.

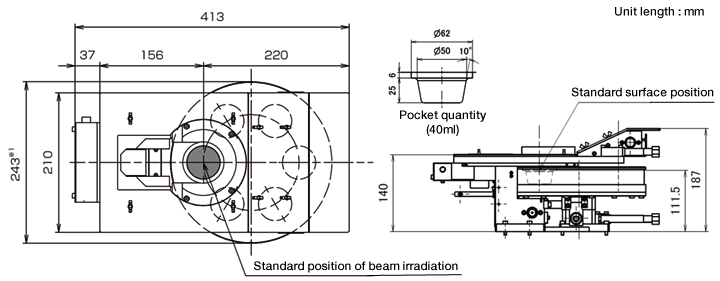

External dimensions

The length of 4-pocket crucible is 220mm

More Info

Are you a medical professional or personnel engaged in medical care?

No

Please be reminded that these pages are not intended to provide the general public with information about the products.