The Akita City Hospital

Benefits of introducing clinical chemistry & immunoassay bridge module

The Akita City Hospital was fully renovated on October 1, 2022. The renovation was aimed for the hospital to

continue serving as a core public medical institute in the region by continuously providing medical services

needed in the region, for five diseases (caner, mental illness, stroke, acute myocardial infarction,

diabetes) and six services (emergency medicine, disaster medicine, remote area medicine, maternal-fetal

medicine, pediatrics, infectious diseases). With 337 general beds, the hospital continues to maintain a

psychiatric ward and a tuberculosis ward to fulfill its role as a public hospital, and also continues to

provide emergency medicine, pediatrics, and maternal-fetal medicine.

In conjunction with the relocation of the new ward, the hospital also renewed the instruments in their

laboratory and introduced a bridge module connecting the clinical chemistry (biochemistry) analyzer

and immunoassay system. We interviewed Ms. Chiba and Mr. Watanabe from the clinical test department about

the introduction process, operation, and the effects.

Akita City Hospital

- New hospital building built in 2022

- Number of beds: 396 (general 337, tuberculosis 14 , mental illness 45)

- Number of clinical departments: 27

- Average number of outpatients:785/day (in 2023)

- Average number of hospitalized patients: 317/day (in 2023)

- Hospital Accreditation Standards:3rd G: Ver. 2.0

Structure and staffing of each department(number of night shift staffs in ().)

- Biochemistry & blood transfusion test: 5 (4 for night shift)

- General & blood test: 3 (2 for night shift)

- Bacterial test: 4 (2 for night shift)

- Physiological test: 14 (4 for night shift)

- Blood collection department: 1 (No night shift)

- Night shift duties are performed by the night shift staffs, 1 to 2 times

in shifts in a month.

Pathology test is handled by the department of diagnostic pathology.

*Figures are current as of February 2025, when the interview was conducted.

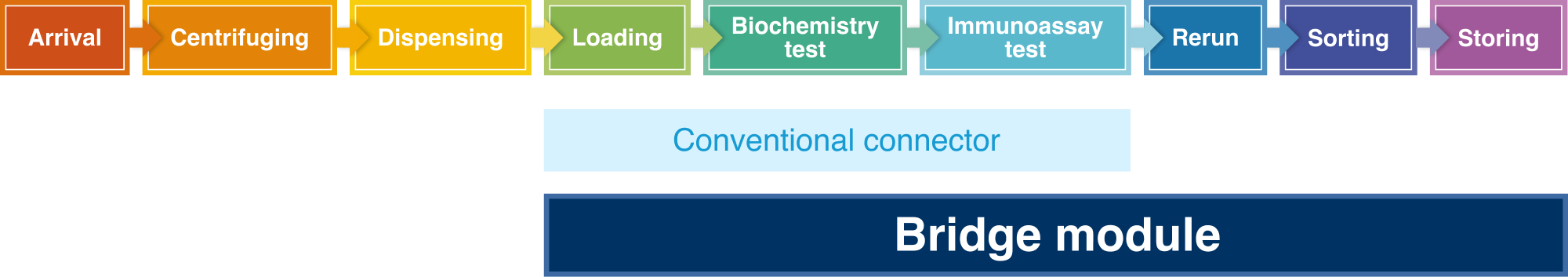

What is a bridge module?

A bridge module can be installed between a clinical chemistry (biochemistry) analyzer and an immunoassay

system to achieve the operation similar to that of a connector. The bridge module itself is essentially a

"mini transport" device. This can also apply for a combination of clinical chemistry analyzers and other

clinical chemistry analyzers.

The bridge module is different from conventional connectors. It is a system that can streamline the entire

routine test flow including not only measurement but also the process before and after measurement.

Additionally, unlike conventional connectors, the bridge module allows users to select immunoassay systems

from a variety of manufacturers.

*1 refer to "selectable models for connection" at the end of the page.

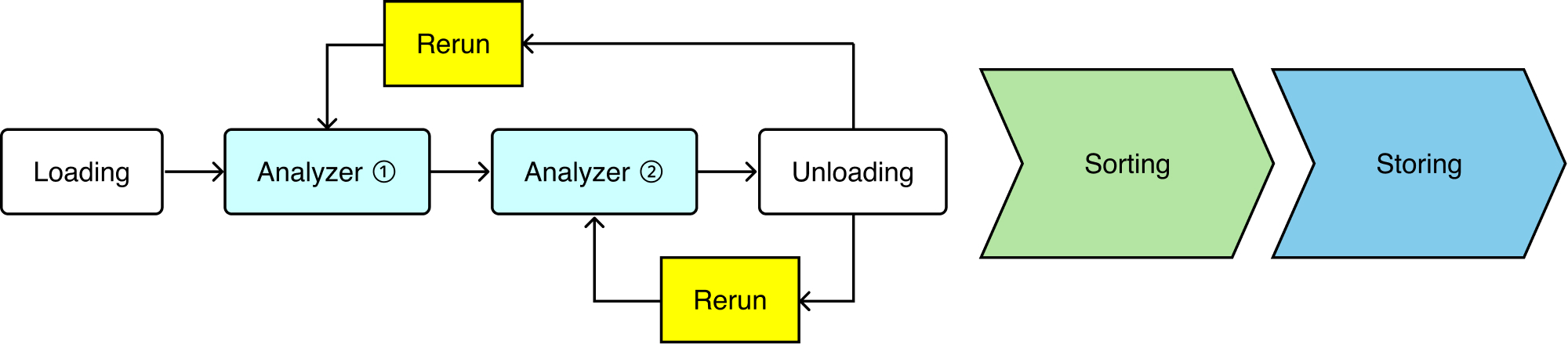

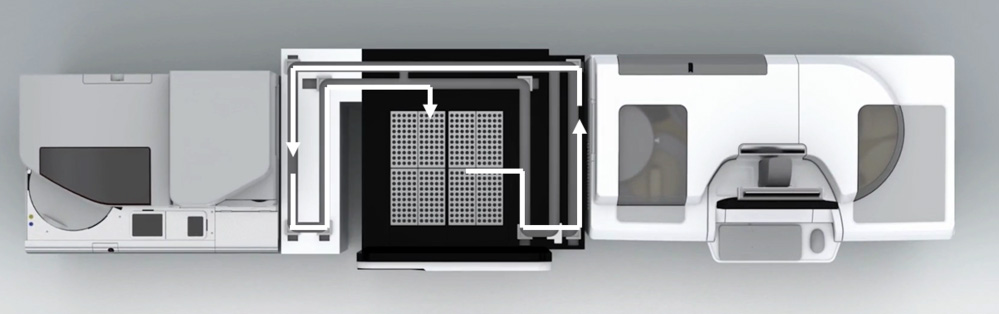

Measurement flow

*2 refer to "Bird's eye view of measurement flow" at the end of page.

Loading: Samples can be loaded without worrying about the orientation of the sample barcode. Samples can be

added in real time.

Rerun: Automatic rerun in real time is possible.

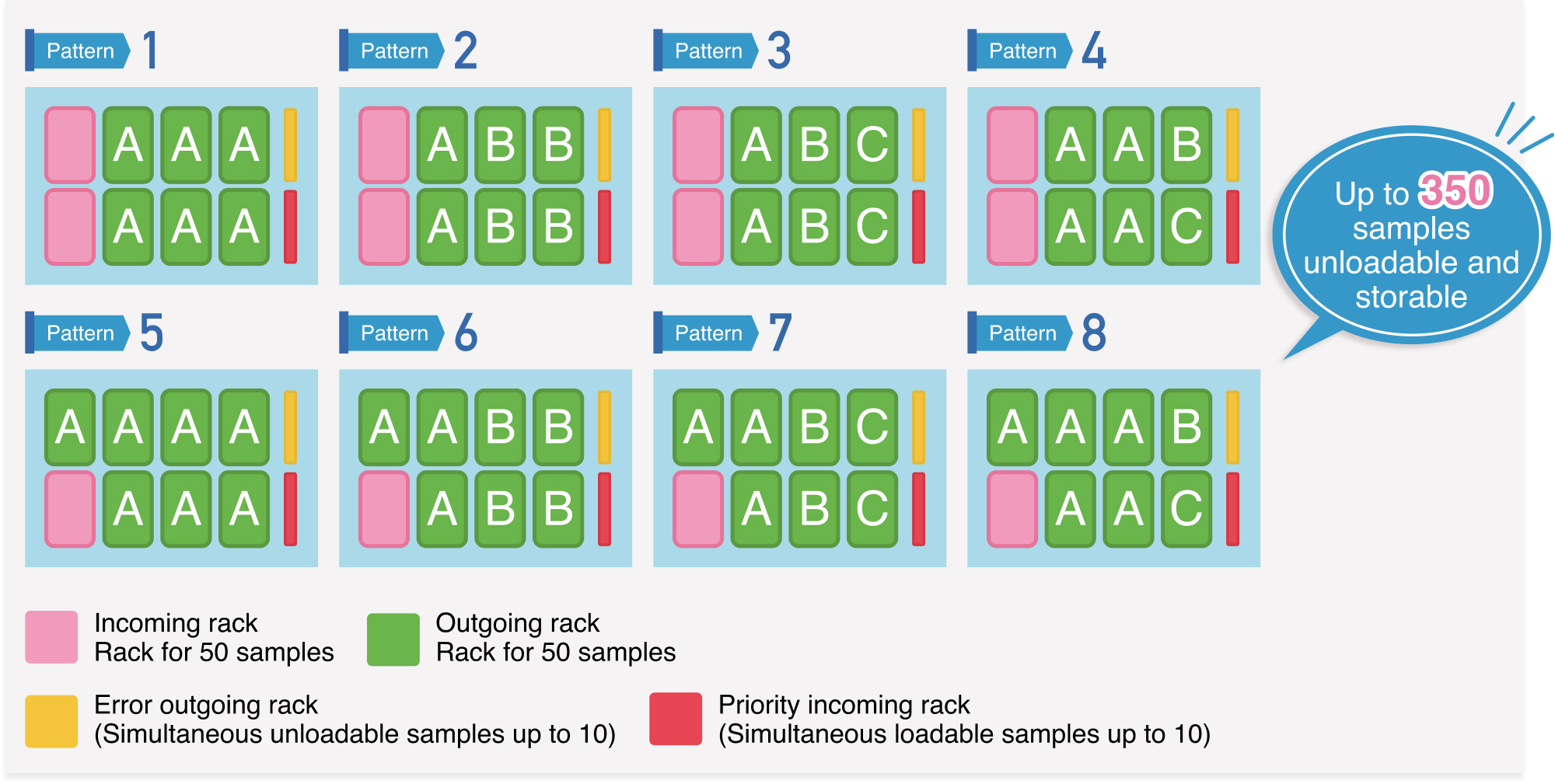

Sorting: Up to three unloading rack patterns can be selected. *3 refer to "Outgoing rack pattern" at the

end of page.

Storing: Samples can be stored in the rack.

The Akita City Hospital uses JEOL's Clinical Chemistry Analyzers BioMajesty 6070 G and JCA-ZS050 in

combination with immunoassay systems and IDS's sample transport systems, respectively.

Regarding the reason of introducing bridge modules, despite the availability of options such as connecting

transports and choosing integrated system, Ms. Chiba and Mr. Watanabe explain, "the primary factor was that

it was not feasible to introduce the fully automated transport system due to cost and space constraints".

Even before the renewal of instruments, the Akita City Hospital placed importance on the throughput and

running costs, and had used JEOL's Clinical Chemistry Analyzer JCA-BM6070 and JCA-BM9130.

At that time, the clinical chemistry analyzers and immunoassay systems were stand alone, and a single blood

collection tube was used for both clinical chemistry and immunoassay tests. Therefore, it was necessary to

manually transfer samples across multiple clinical chemistry analyzer and immunoassay systems, in some cases

requiring transfer across as many as four systems. This process was time-consuming, and during periods of

low staffing, it resulted in significant losses in TAT (Turn Around Time). Therefore, they decided to

introduce bridge modules to minimize the sample transfer and shorten the TAT.

Various data was collected regarding the introduction, and discussions were made with manufacturers. At that time, there were only a limited number of manufacturers with a proven track record of connecting clinical chemistry analyzers and immunoassay systems as bridge modules. Nevertheless, in expectation to their flexible response, they decided to request IDS to provide the sample transport system.

When a measurement is needed by both of clinical chemistry and immunoassay systems, it is necessary to transfer the sample when one analysis is completed, to the next system. This time, in order to automate the transfer, they decided to "consider a system on the premise that the systems are connected by using transfer systems".

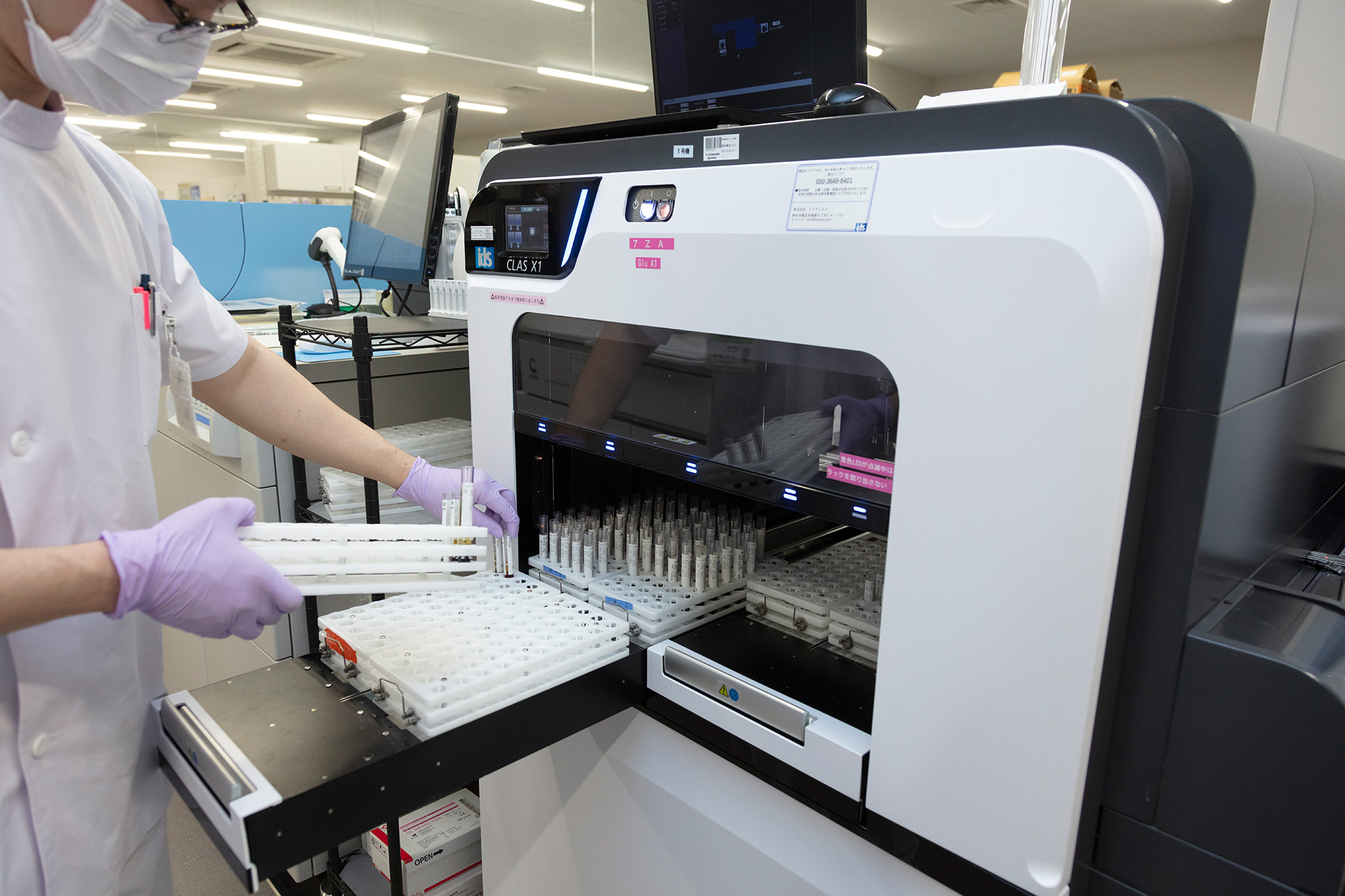

IDS's sample transport system main module

IDS's sample transport system main module

2 Lines Prepared - for Day time/Weekdays and for Nighttime/Holidays

In considering the system requirements, what was first considered was "which clinical chemistry analyzer to select". This was easily decided to be the BioMajesty 6070 G and the JCA-ZS050. Especially, the BioMajesty 6070 G was a successor model of the JCA-BM6070 which they used to utilize at the laboratory and felt the benefits of high throughput and good running costs. It was natural to come to this conclusion to use the JCA-ZS050 for night/holidays line, and the BioMajesty 6070 G for full operation during daytime/weekdays.

Next was the immunoassay system. For immunoassay system, the AIA-CL2400LA was

selected for usage during daytime and weekdays, and for urgent items at night and on holidays.

On the other hand, for the system for daytime and weekdays, the LUMIPULSE L2400 was selected, as it is

capable of measuring tumor markers which are not tested on night and holidays and it holds a high

throughput.

System No. 1: JCA-Z050 connected with AIA-CL2400LA (made by Tosoh Corporation)

System No.2: BioMajesty 6070G connected with LUMIPULSE L2400

(made by Fuji

Rebio Inc.)

As for the combination, the JCA-ZS050 and AIA-CL2400LA (made by Tosoh Corporation) as system No.1 and the BioMajesty 6070 G and the LUMIPULSE L2400 (made by Fuji Rebio Inc.) as system No. 2, are connected by using IDS's sample transport system main module.

The reason to connect the JCA-ZS050 and the AIA-CL 2400LA was because they were used on night and holidays. High throughput is not needed for nights and holidays, but urgent item measurement is required. Therefore, the JCA-ZS050 which has lower throughput than the BioMajesty 6070G, and the AIA-CL2400LA which can measure BNP, MYO and presepsin were connected. On the other hand, as for the BioMajesty 6070 G and the LULMIPULSE L2400, operation on weekdays was more focused. So, the BioMajesty 6070 G of high throughput for measuring samples and the LUMIPULSE L2400 which can measure tumor markers which are not tested on night and holidays were selected.

On the left: Ms. Chiba, on the right: Mr. Watanabe

Connection at early days - not went well as expected

IDS's system can separate the incoming lane where samples are loaded, and the outgoing lane where samples are returned after dispensing is completed. However, the patterns of assigning the rack were fewer than the actual laboratory operation. Originally, they wanted to assign the outgoing lanes to 1. clinical biochemistry sample, 2. sugar/urine sample, 3. untested sample or rerun. However, it was not possible in the first place. As a result, the outgoing lanes easily became full, causing frequent replacement work of racks, the burden of the work, and affecting the operation's efficiency.

However, thanks to IDS's flexible response, the specification was changed. Now the assignment of racks has been realized as desired, resulting in a smooth operation.

No more mistakes, and more time and mental capacity

Before the introduction, once the test has been completed with one system, a sample needs to be moved by human hand to the next system. Thus, handling of a sample was complicated, resulting in overlooking mistakes of measurement.

After the introduction of the system, they only need to enter the samples to the IDS's sample transport

system main module, simplifying the workflow, thus mistakes to overlook measurements hardly occurs. Reruns

and additional tests used to require time-consuming searches for samples. But now reruns can be performed

automatically from the primary sample. A sample search function can be used to immediately locate samples

for cross reruns and additional tests, thereby reducing the workload. As a result, the number of personnel

required for testing has been reduced from five to four. The results are reported to the clinic with TAT

from 20 to 30 minutes instead of 30 to 40 minutes.

The major benefit for the medical technologists is that they now have more time and mental flexibility.

Before, they were busy working from 8:30 am to 5 pm without rest. When they were moving samples from one

system to another, they sometimes wondered if this was the work of a medical technologist.

Now they have more time to check electronic medical records and prepare training materials when they have free time. They also said that now it is necessary for staff to take their vacations properly, scheduling them is becoming easier.

Hope for patients to feel the benefits

In the future, they plan to conduct periodic staff training including the staff members with limited experience to improve their technical and academic skills. A long-term objective is to make the laboratory capable of response in a disaster.

Back to TAT, now the TAT for testing is becoming 30 minutes. However, our patients do not seem to feel that the test time is shorter because of the long waiting time in the blood collection room. We would like to resolve the waiting time for blood collection and provide results within 1 hour of the arrival at the hospital including the time required for blood collection and blood test time. That is our goal now.

Supplementary information

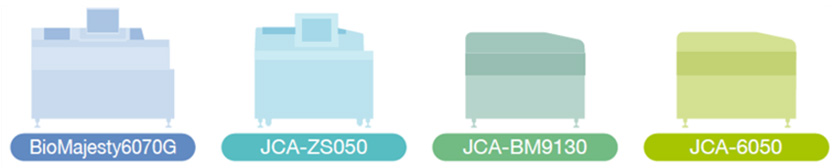

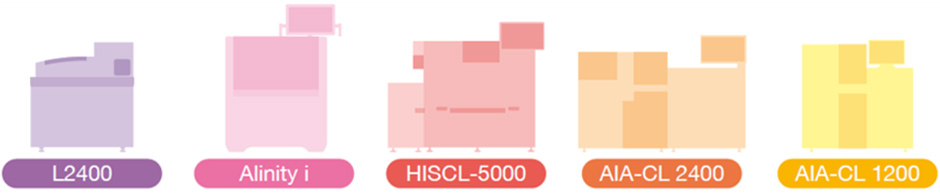

*1 Selectable models for connection

Clinical Chemistry Analyzer 4 Models

Immunoassay System 5 Models

Combination of Clinical Chemistry Analyzer & Clinical Chemistry Analyzer Possible

*2 Bird's eye view of measurement flow

*3 Outgoing rack pattern

Example of outgoing rack layout

- Storing samples for clinical chemistry tests and immunoassay tests separately

- Request to store samples for outsourcing and manual method (Test for Syphilis, etc.) separately can be met.

- A Normal unloading

- B Outsourcing sample (Sample for next outsourcing)

- C Separate test(manual method, etc.), etc.

BioMajesty™ is a registered trademark of JEOL Ltd.

Company names and product names in this article are registered trademarks of their respective companies.