FEATURE

Enabling seamless observation and analysis

Further strengthened FIB processing capabilities. Greatly improved SEM imaging by a new optical column. Improved operability with linkage capabilities.

FIB : Further strengthened processing capabilities

- ・Enhanced control system

The vector scan system allows for smooth processing of an arbitrary shape.

Simple 3D observation & analysis is enabled. - ・Large ion beam current up to 90 nA

High-speed processing of the specimen is enabled.

SEM : Improved imaging performance

- ・High resolution at low accelerating voltage

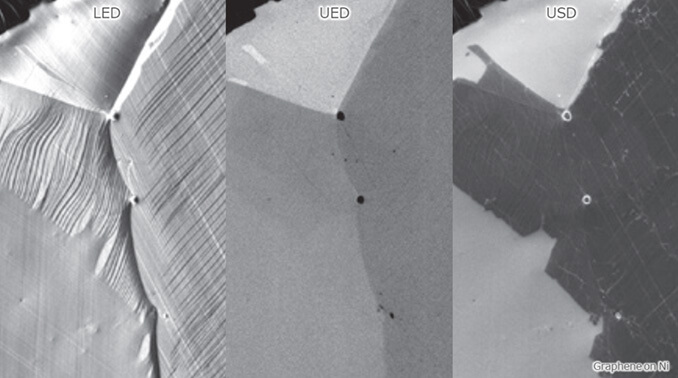

Combination of a hybrid conical objective lens and GENTLEBEAM™ achieves high resolution at low accelerating voltage (1.6 nm at 1 kV). - ・Acquisition of a variety of images

Newly added UED & USD detectors enable acquisition of a variet y of SEM images that contain information on properties, chemical compositions and crystal structures. - ・High resolution at large probe current

Combination of an “in-lens Schottky electron gun” and an aperture angle control lens(ACL) maintains high resolution at large probe current, allowin g for fast analysis.

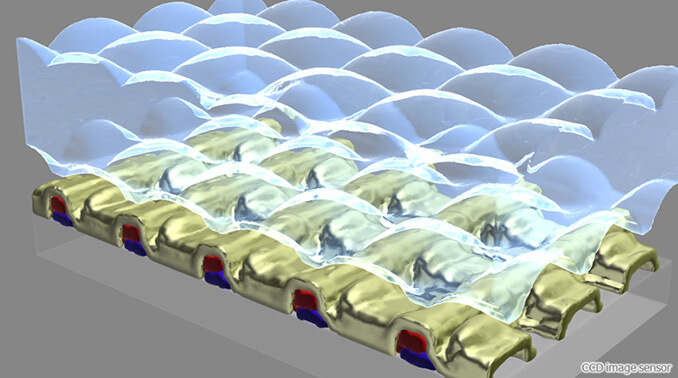

3D observation and analysis

- ・Stable automatic measurement

The Slice and View system (standard component of the JIB-4700F) enables automatic repetition of processing, observation and analysis. - ・Easy reconstruction

After the repeated steps, a 3D reconstructed image is acquired by the 3D-reconstruction software (IB-67020STKV)* from the serially-acquired data.

APPLICATION

Versatile solutions offered by FIB-SEM

Cross section specimen preparation, TEM specimen preparation, 3D observation, 3D EDS analysis, 3D EDSD analysis, Processing of fine shapes

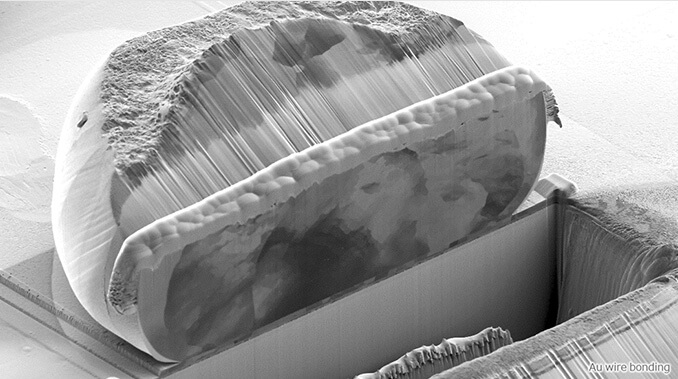

Cross Section

The JIB-4700F Multi Beam System allows for seamless operations from protective-film preparation, specimen milling to cross section observation and analysis. The FIB column enables processing with a largecurrent Ga ion beam (up to 90 nA). This largecurrent processing is particularly effective for a large-area specimen preparation.

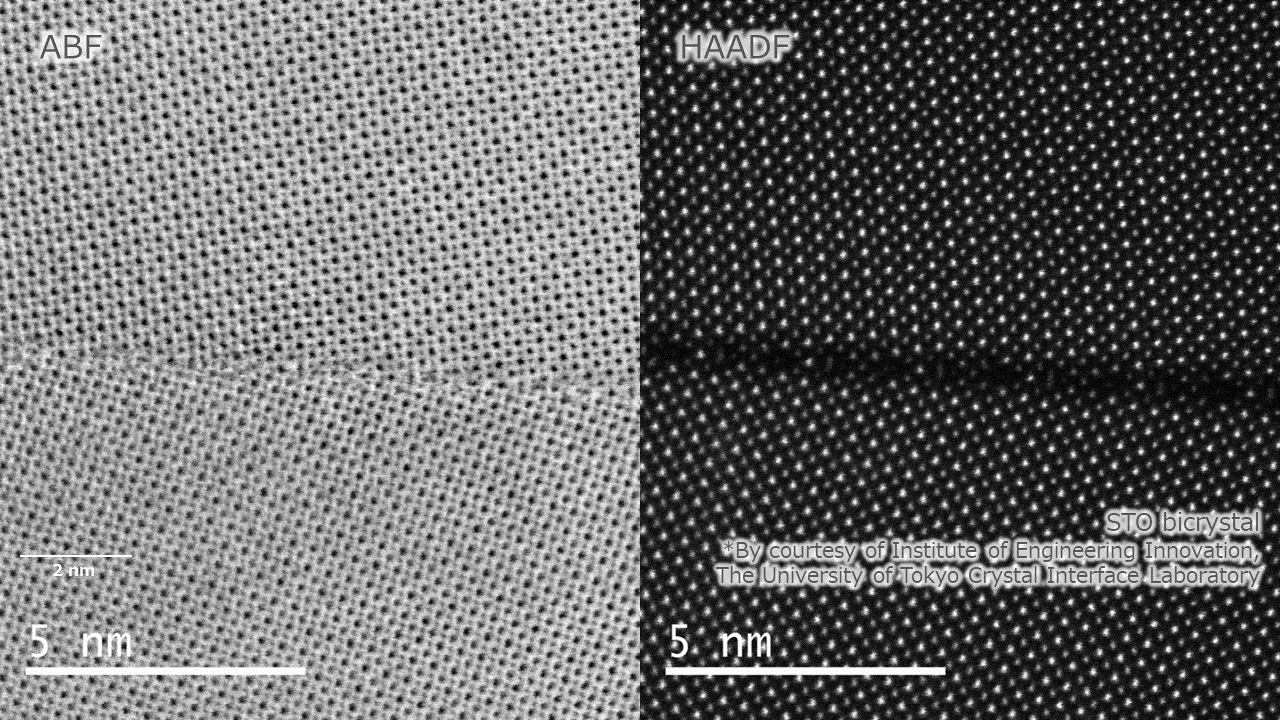

TEM Sample

The combination of the JIB-4700F and the manipulator system allows for smooth TEM specimen preparation. The use of the backscattered electron detector enables you to observe the progress of FIB milling with a high-resolution SEM image. The JIB-4700F enhances operation efficiency, such as detection of final milling end-point for preparation of TEM specimens.

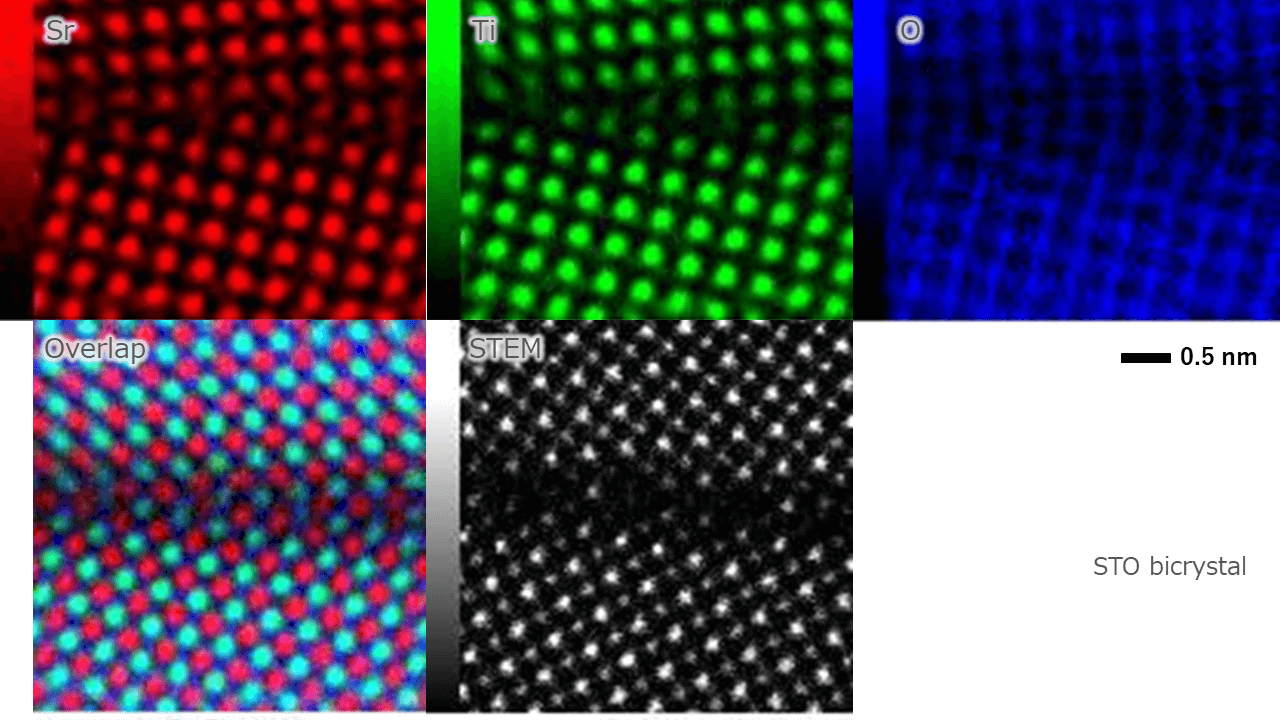

3D-EDS Analysis

3D-EDS* enables automatic serial steps of both FIB milling with an incident ion beam normal to the specimen surface and EDS analysis using a SEM probe.High resolution at large probe current allowin for fast EDS analysis.

3D-EBSD Analysis

An EBSD detector*, which is optimally placed,enables processing and analysis with no stage movement. This feature provides high positional accuracy of data acquisition with a shortened time.